Patents

Literature

32 results about "Coffee roaster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coffee roasting control system and process

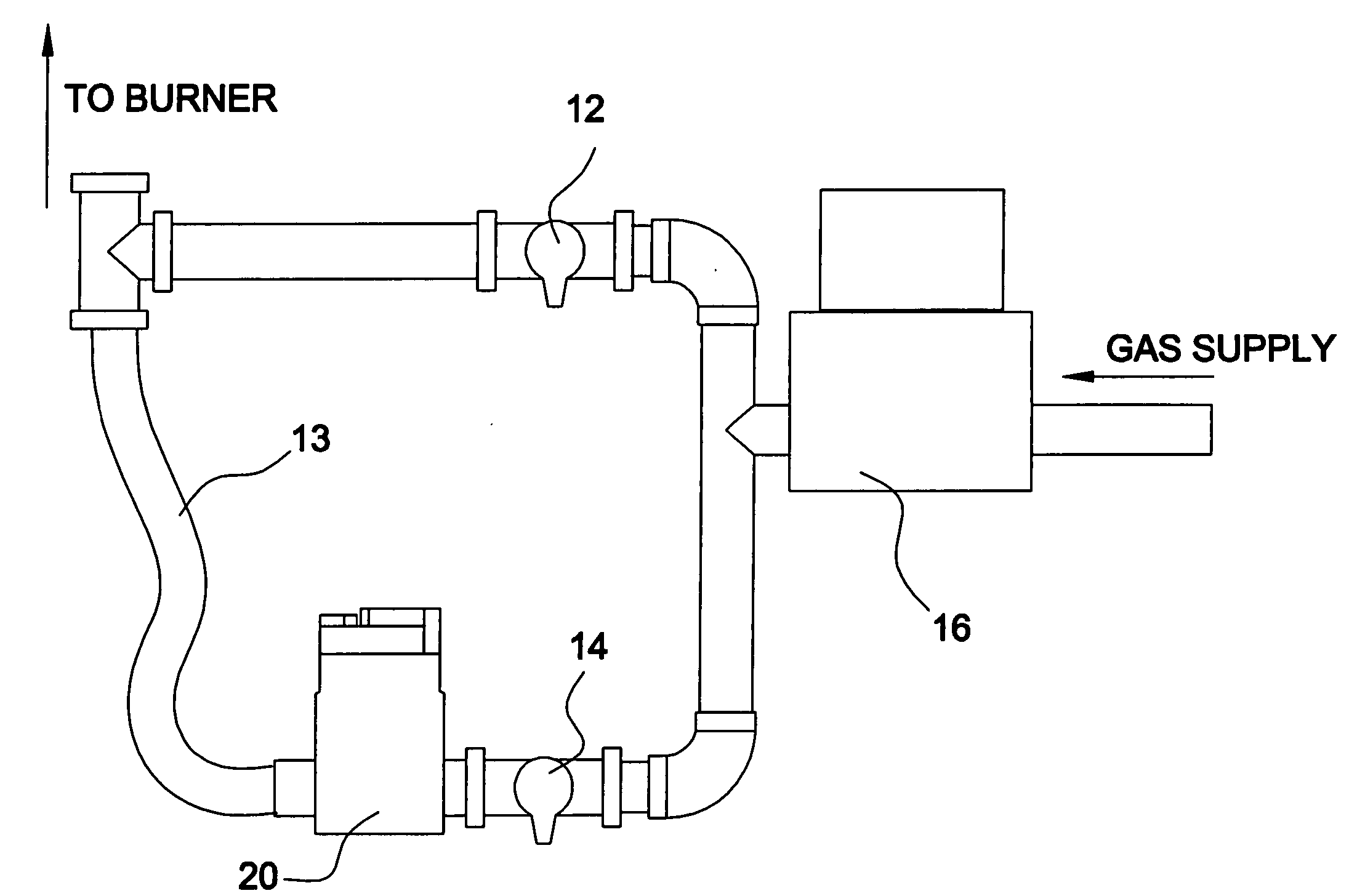

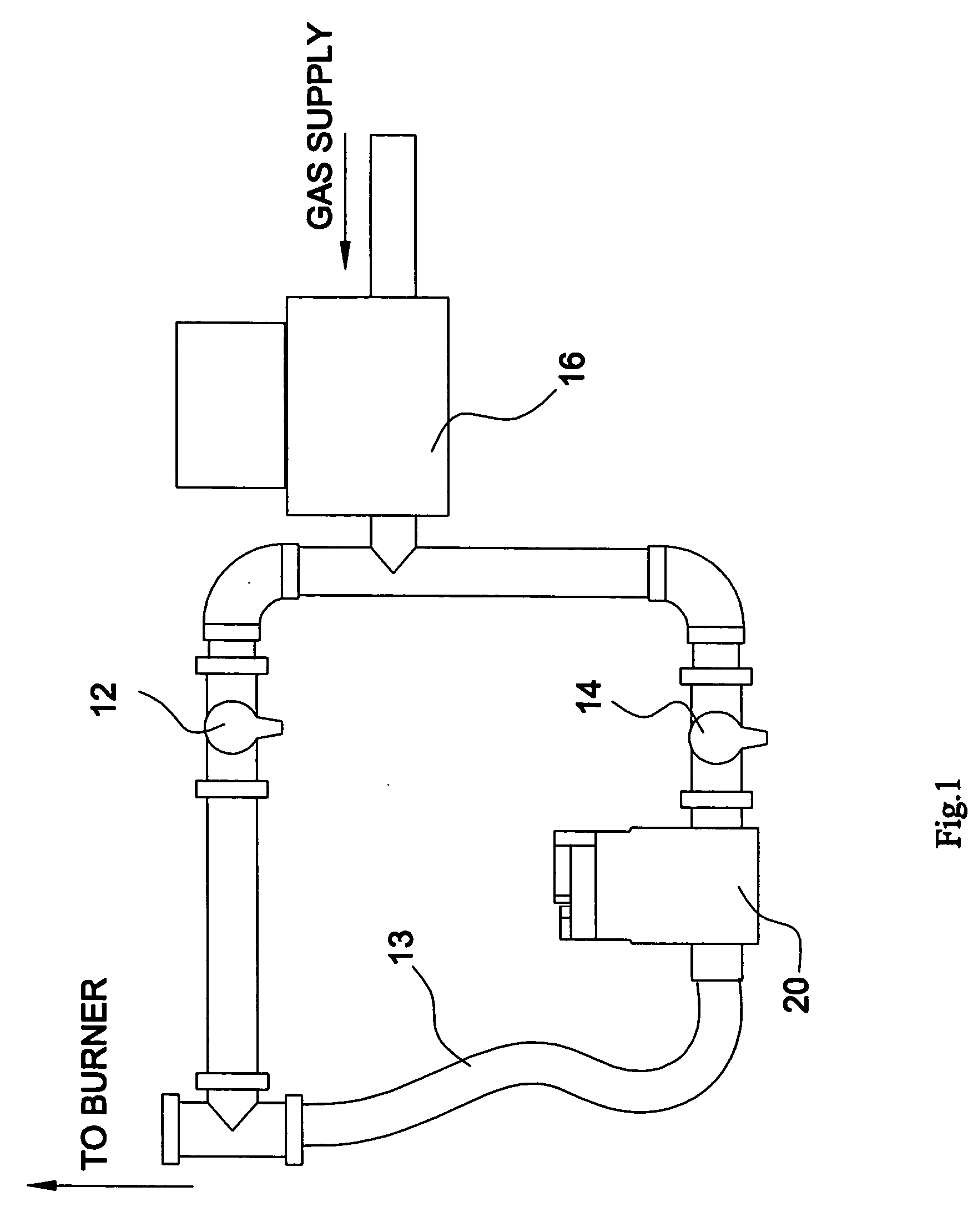

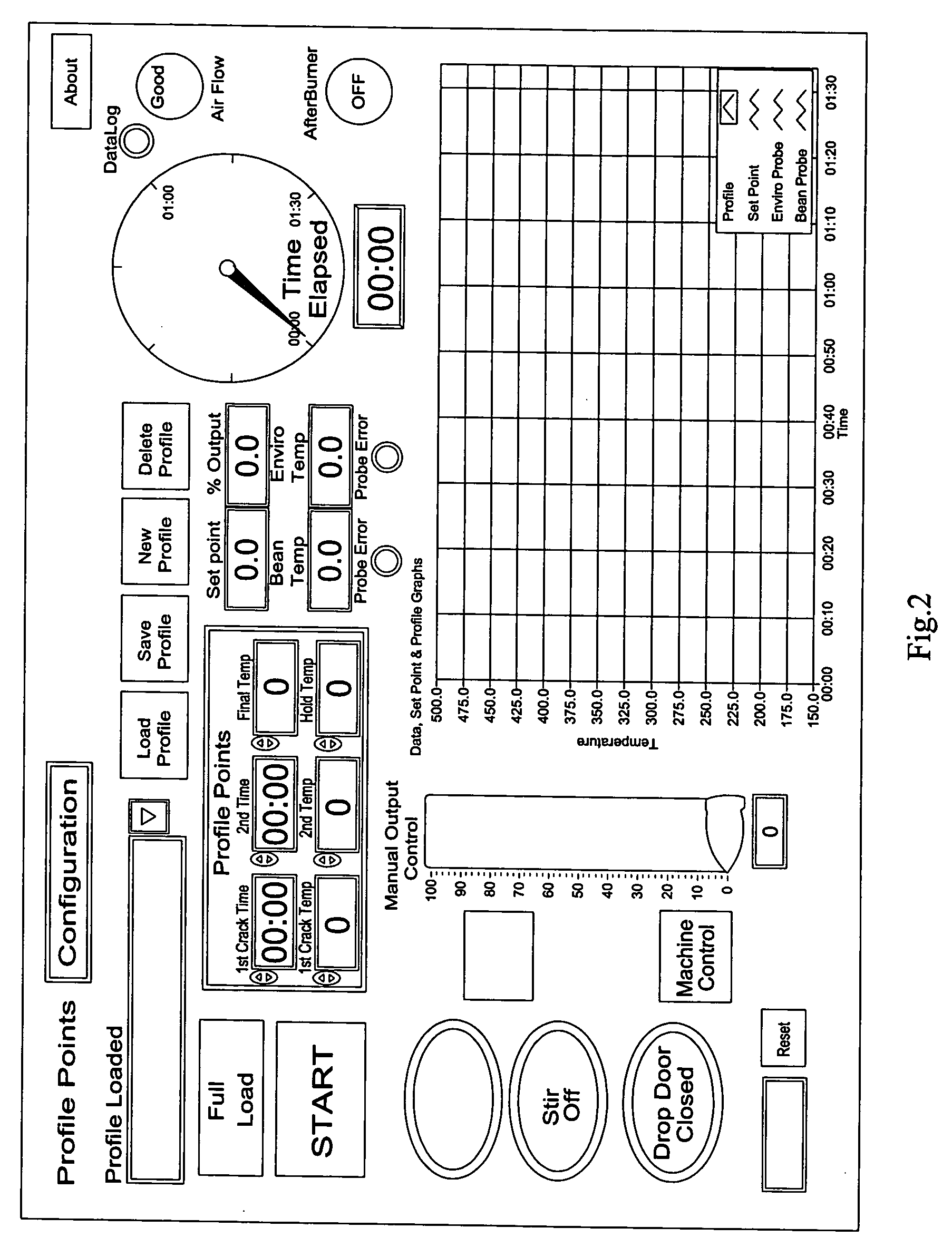

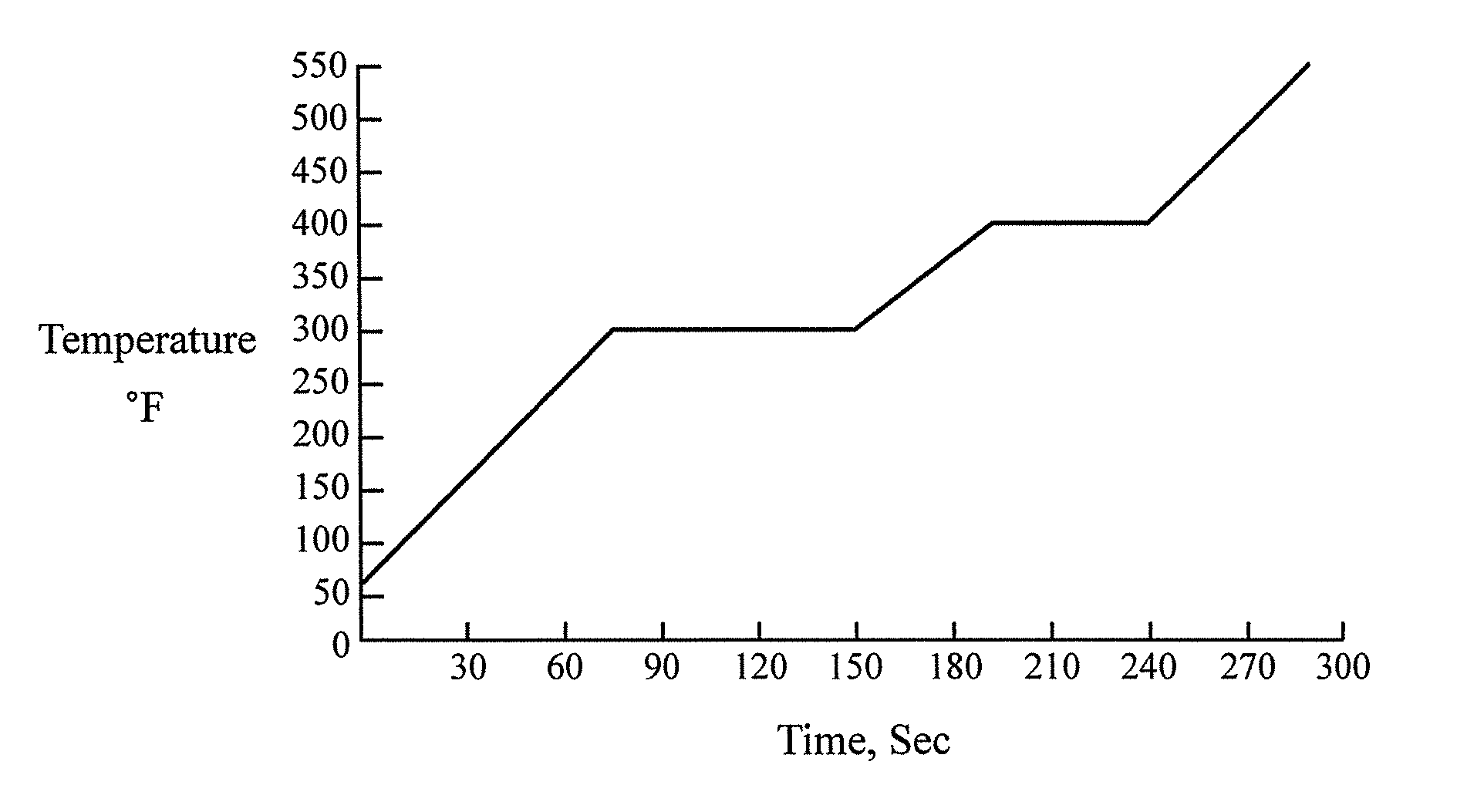

The inventive process comprises micro-processing means utilizing a coffee roaster control algorithm for controlling the roast process of coffee beans. The algorithm utilizes curve fitting techniques to calculate polynomial coefficients used in generating a smooth curve to control the coffee bean temperature during the roast process. Through the use of multiple set points and actual historical data, the polynomial coefficients are generated. The coefficients are then used to plot a graph that indicates the path the roast process will try and maintain.

Owner:AMBEX

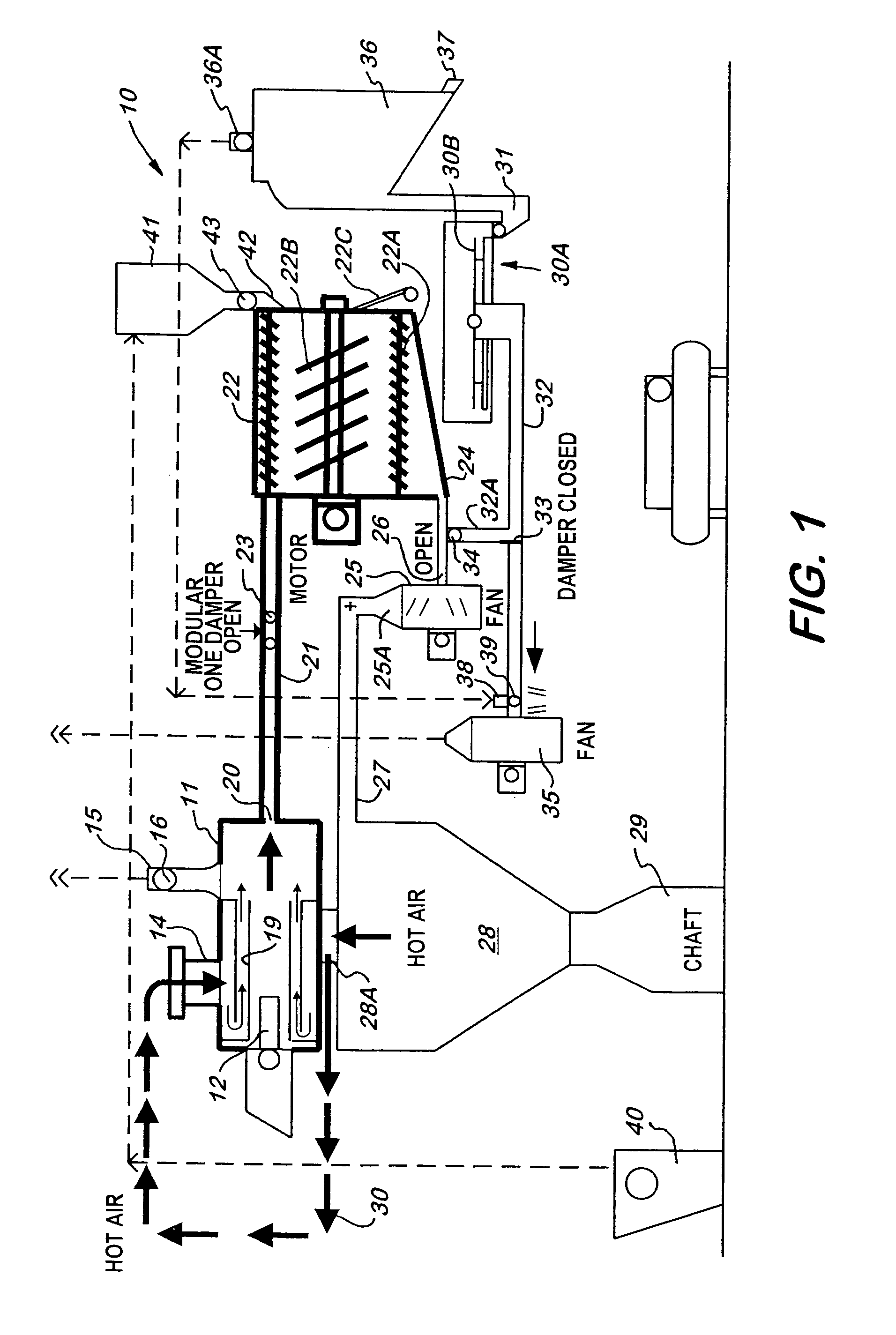

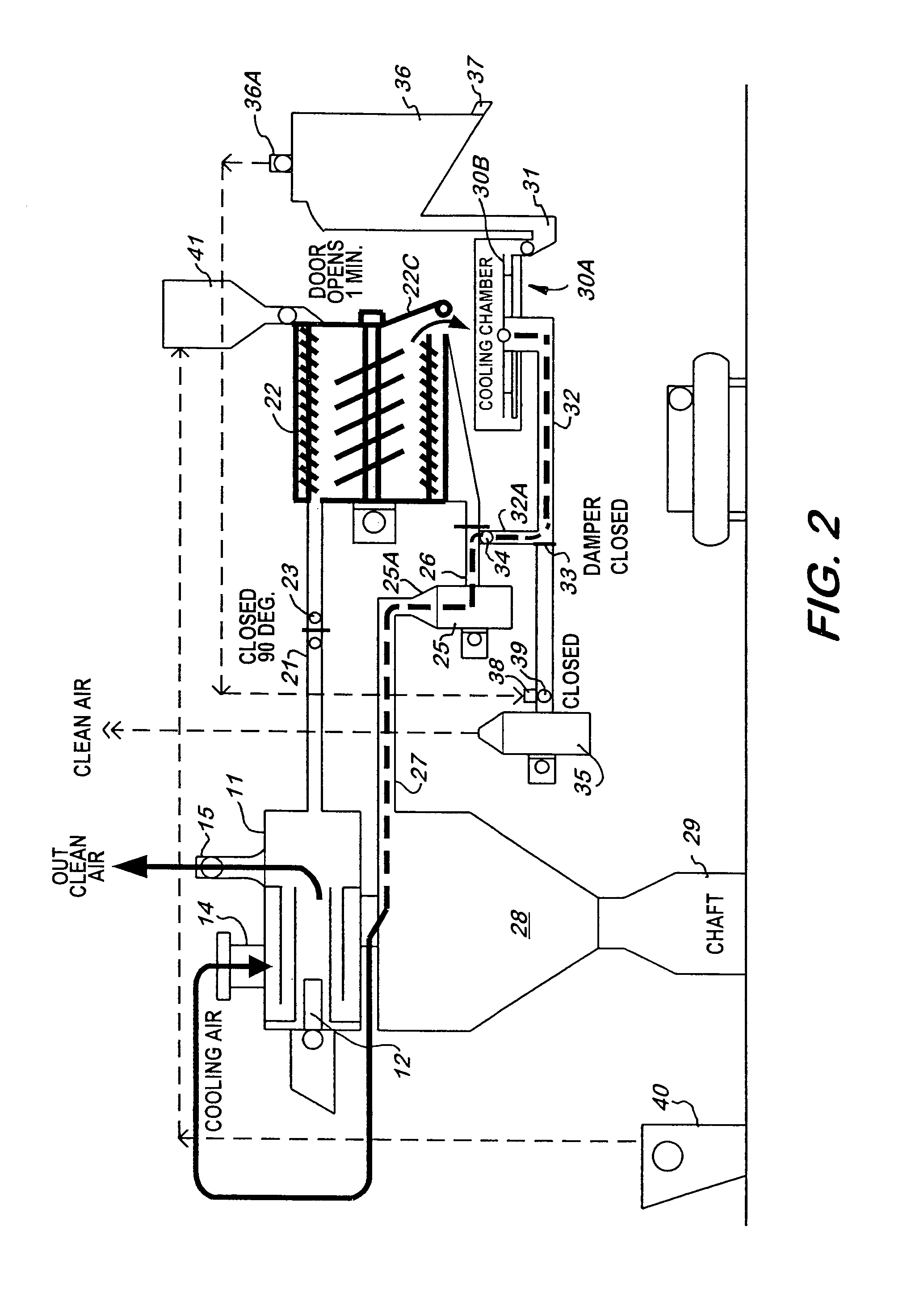

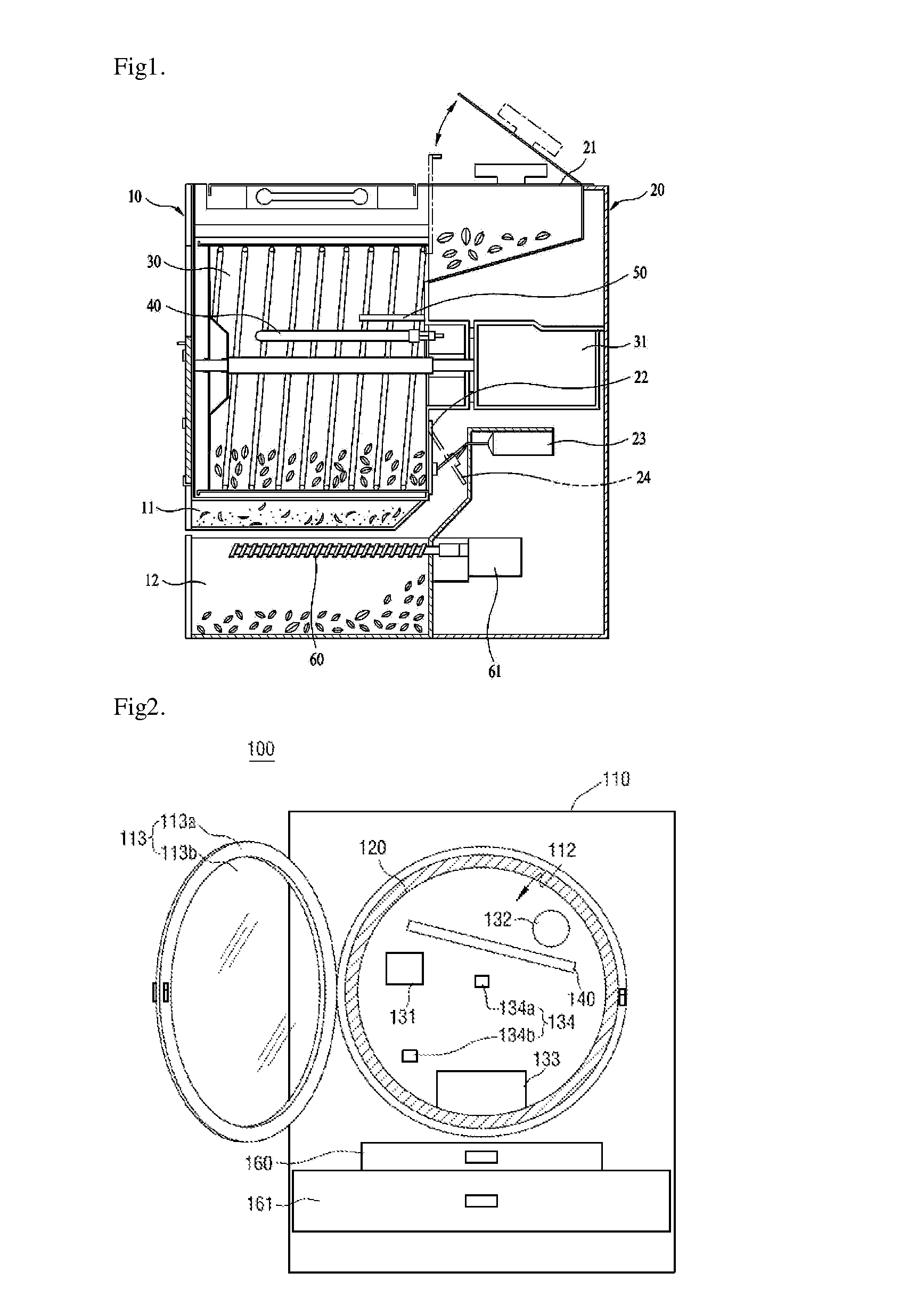

Coffee roasting apparatus and method

InactiveUS7143686B1Reduce the temperatureAir-treating devicesMilk preservationCombustion chamberCooling chamber

A coffee roaster that includes a combustion chamber and a connected roasting oven in which the heating gases for roasting the coffee beans are recirculated to the combustion chamber wherein the coffee bean chaff is separated from the recirculating heating gases prior to venting to atmosphere, and an associated cooling chamber wherein the roasted coffee beans are cooled in a two-stage-heating cycle wherein the cooling air is recirculated to the combustion chamber to be reheated to roasting temperatures and vented to atmosphere during the second stage of cooling. The coffee beans being de-stoned as the cooled coffee beans are conveyed from the cooling chamber to the discharge hopper.

Owner:SANDOLO RAFFAEL

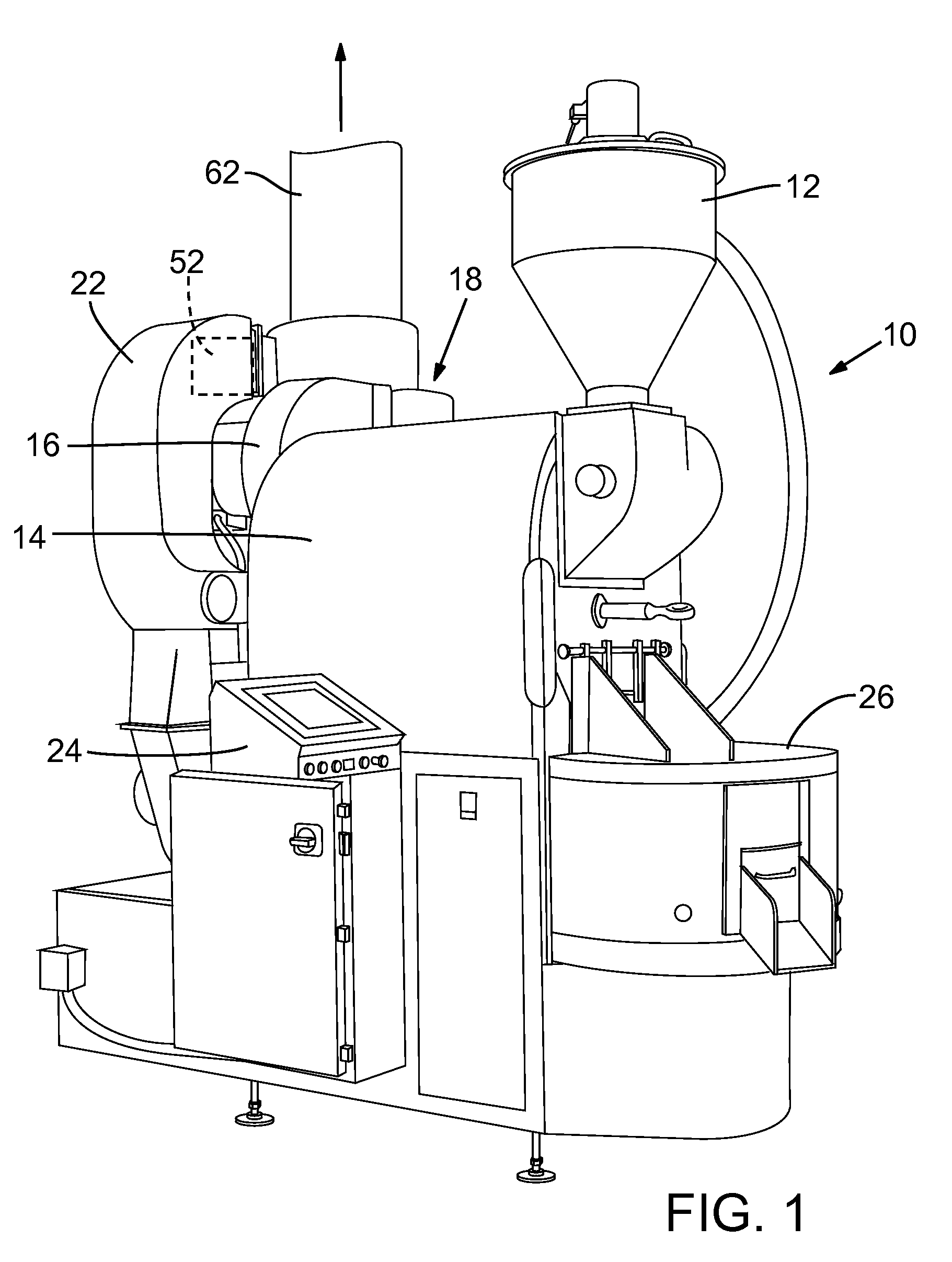

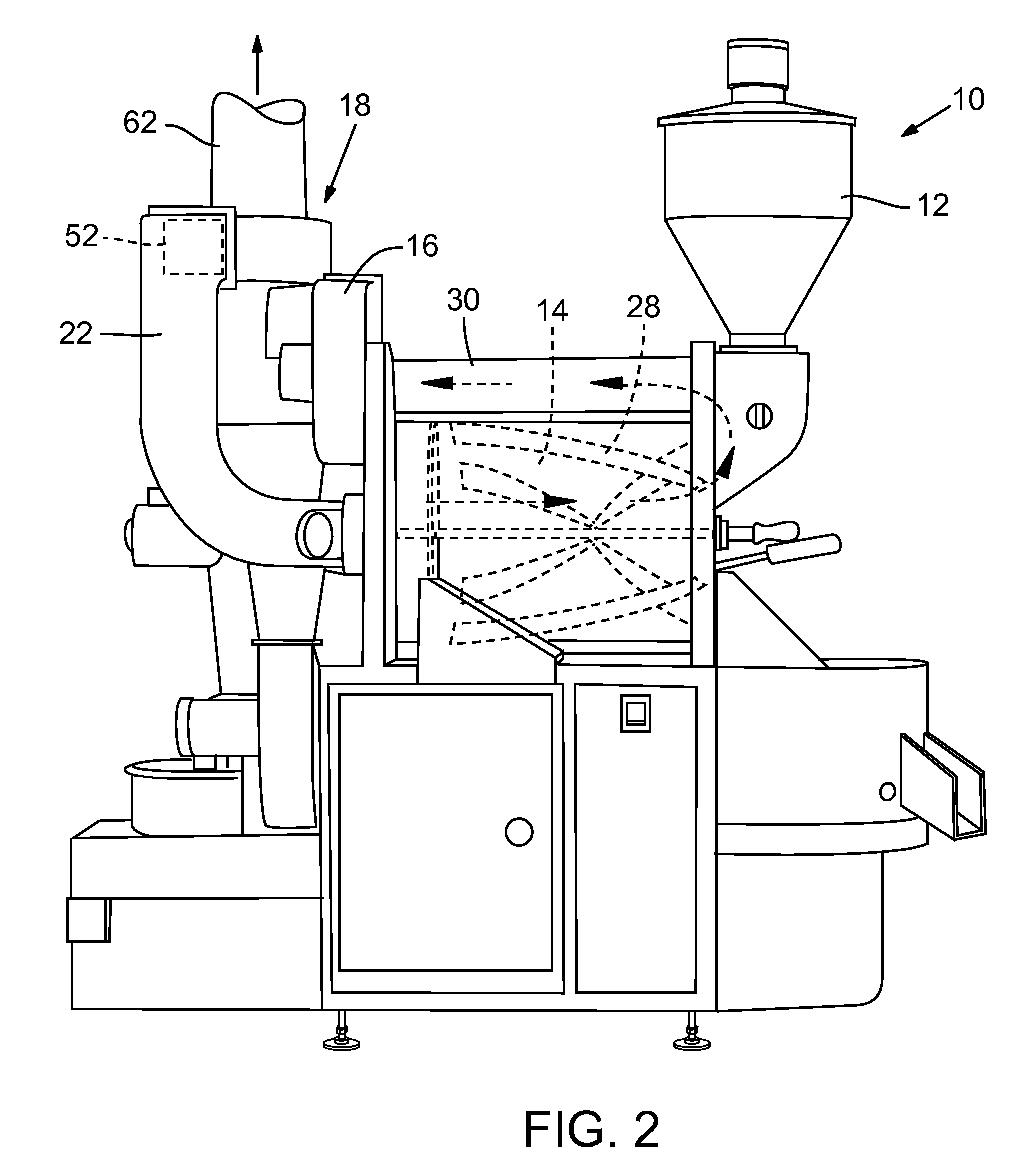

Coffee roasting machine and system and method of use

A coffee roasting machine for roasting coffee, particularly in small batch sizes for sale and distribution to individual customers. The coffee roaster is suitable for placement entirely within a retail sales outlet or establishment and for being operated by any person, such as, an employee, customer, or patron who has little or no knowledge, skill, or experience in roasting coffee beans. The coffee-roasting machine selects an appropriate coffee roasting instruction set, stored internally, that corresponding to information input into the coffee-roasting machine for roasting a particular type of coffee bean or coffee bean blend to a desired roast level. The information is integrally included on a package of coffee beans for roasting and is directly readable by the machine or manually inputtable by an operator.

Owner:BRESSNER GORM +6

Fluidized bed coffee roaster

A fluidized bed coffee roaster controls air flow and / or temperature to maintain a desired time-temperature roast profile. The roaster may also provide a two stage quenching cycle for rapidly cooling roasted coffee beans to ambient temperature. In a first stage of the quenching cycle unheated air is passed through the roasted beans while they are still in the roasting chamber of the fluidized bed roaster. In a second stage of the quenching cycle which is carried out outside of the roasting chamber, in a fluidized bed quenching station, unheated air is flowed through, and fluidizes, the roasted coffee beans cooling them to ambient temperature.

Owner:JAVA MASTER INT LLC

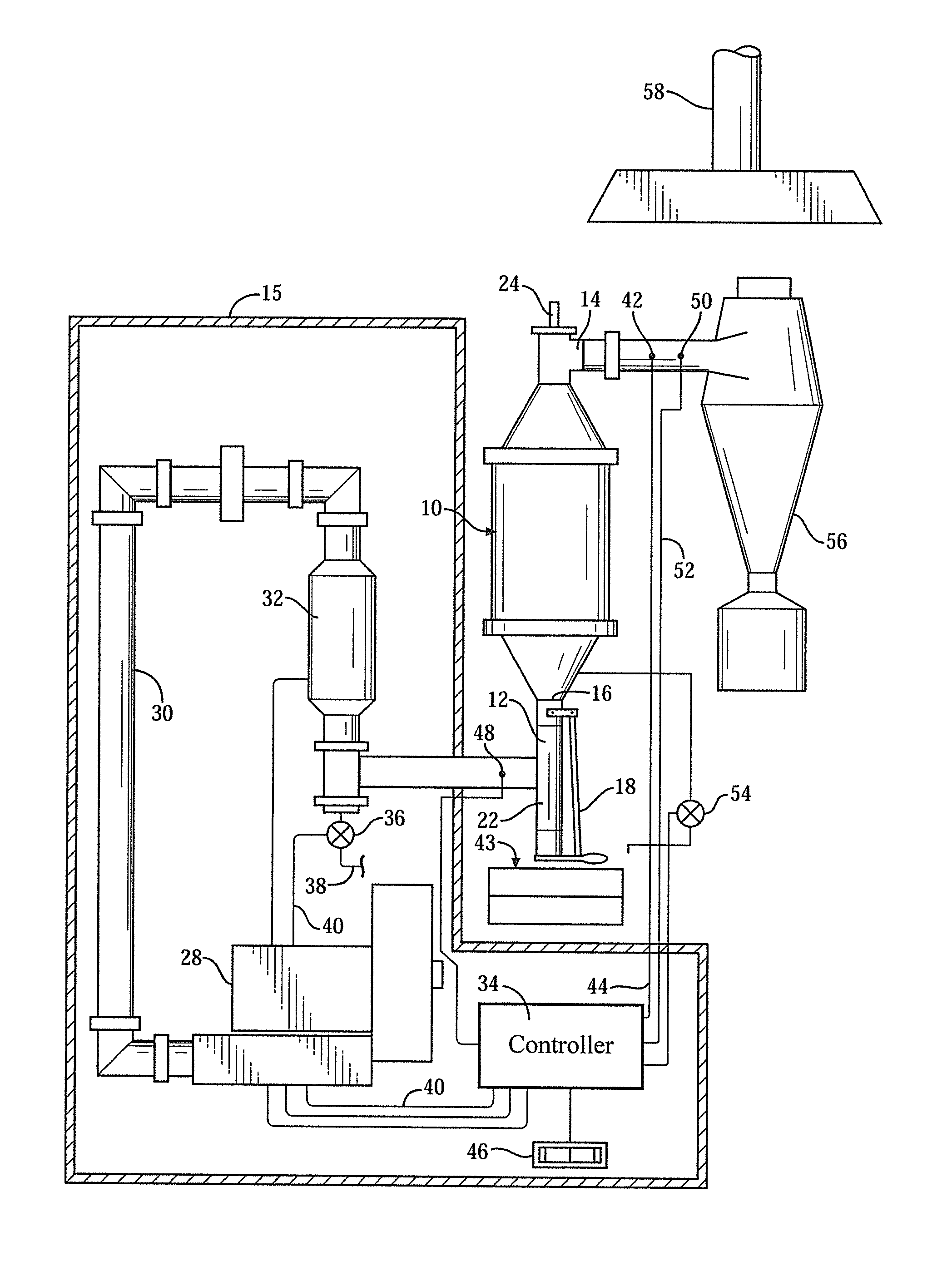

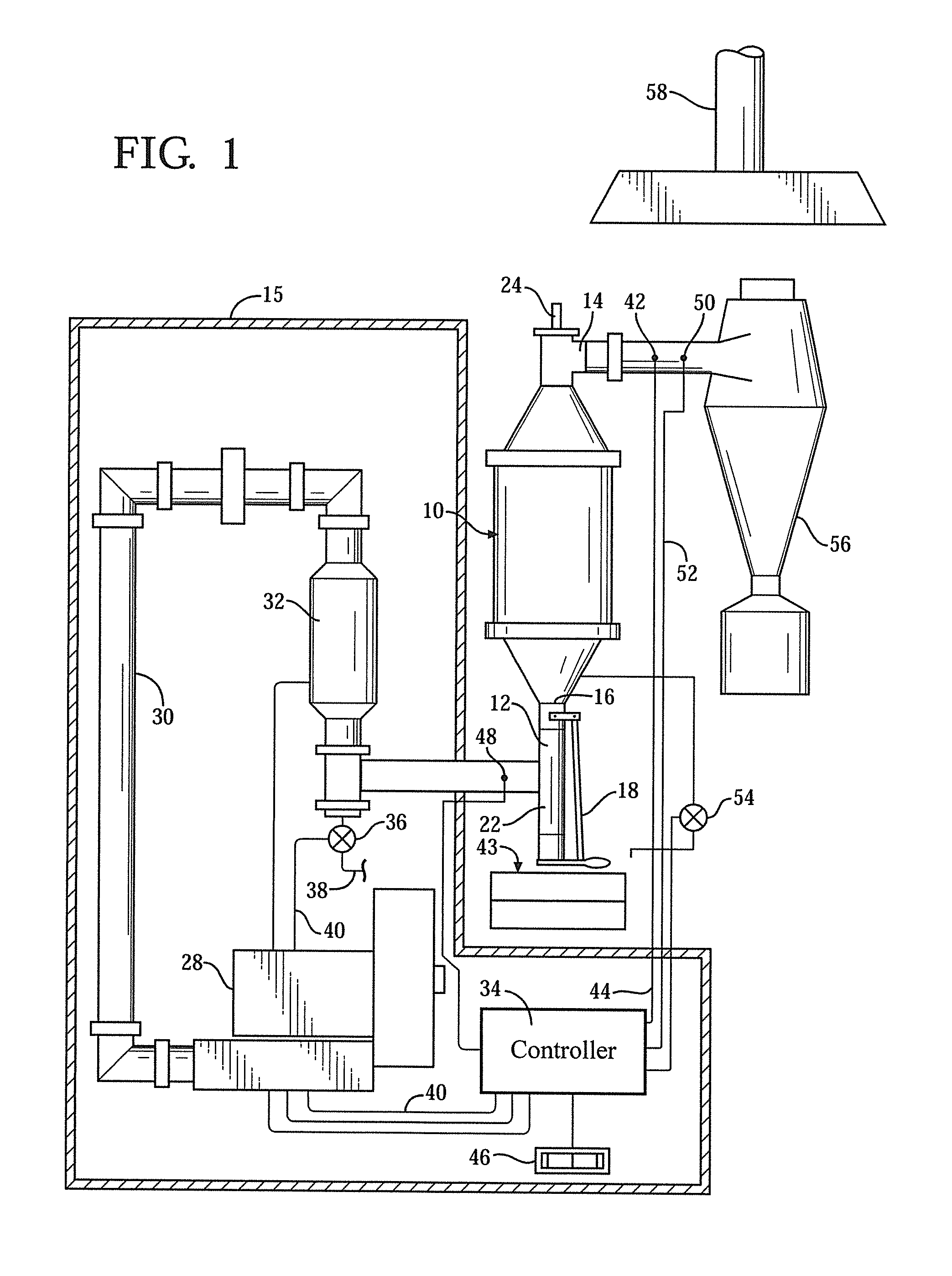

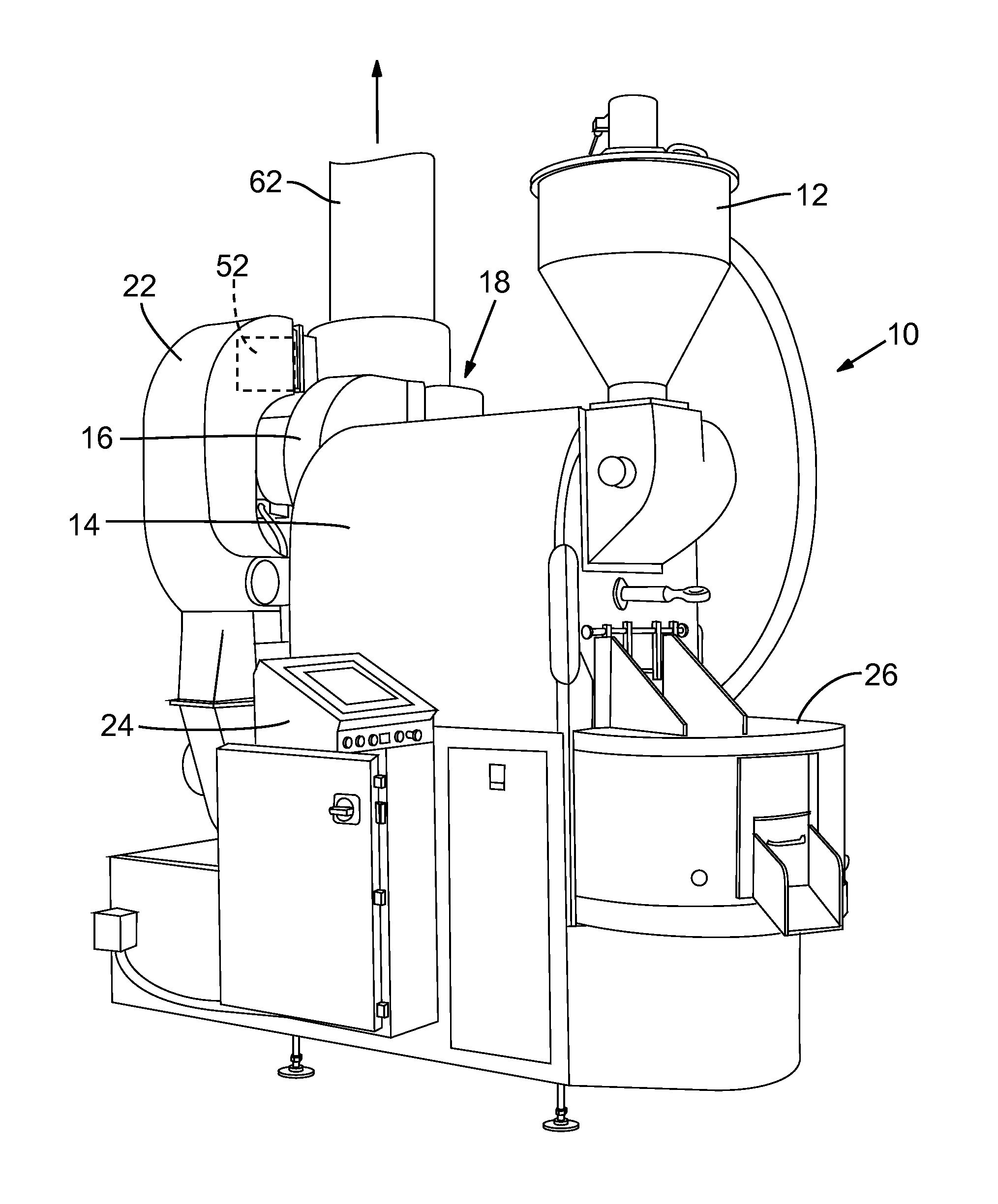

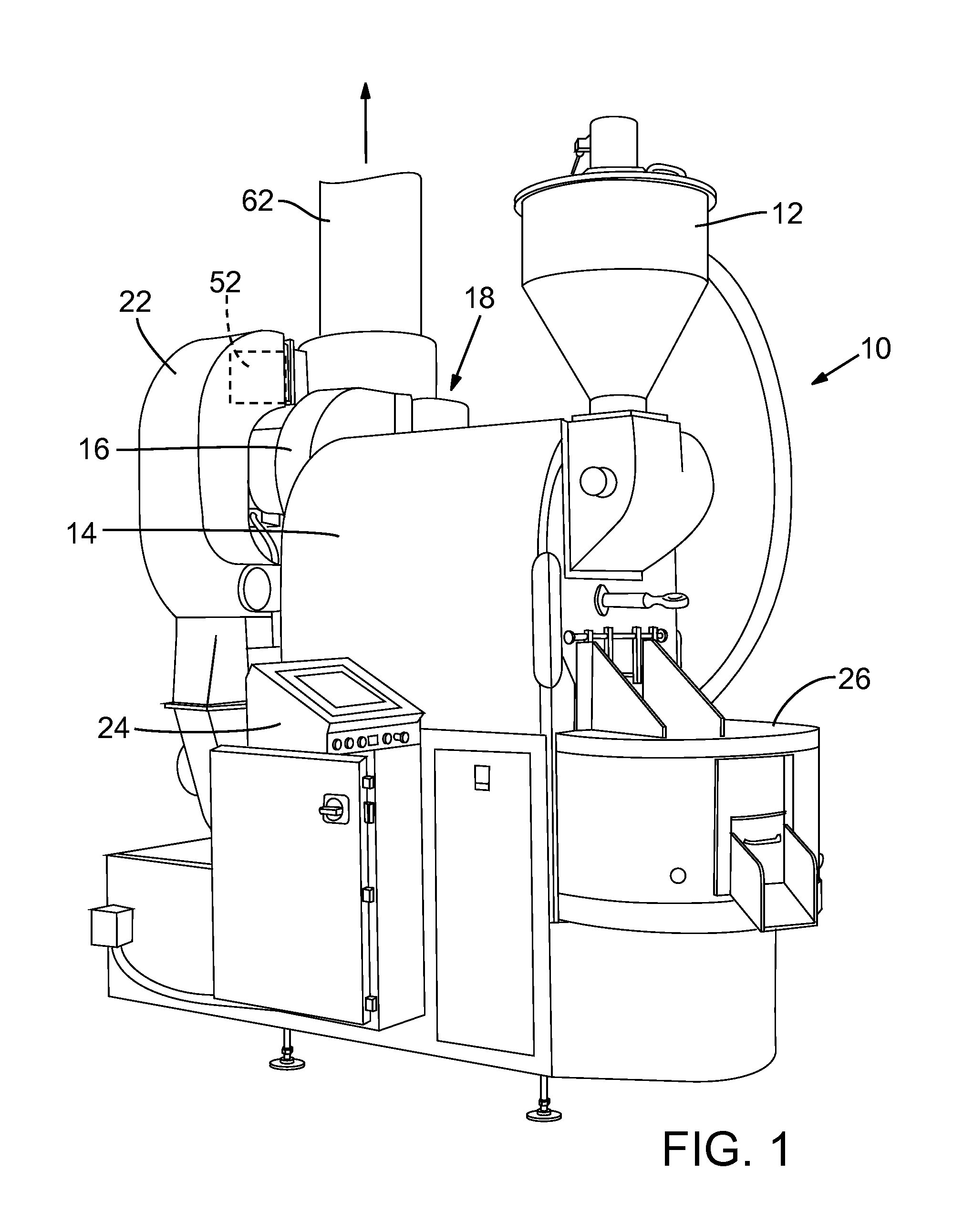

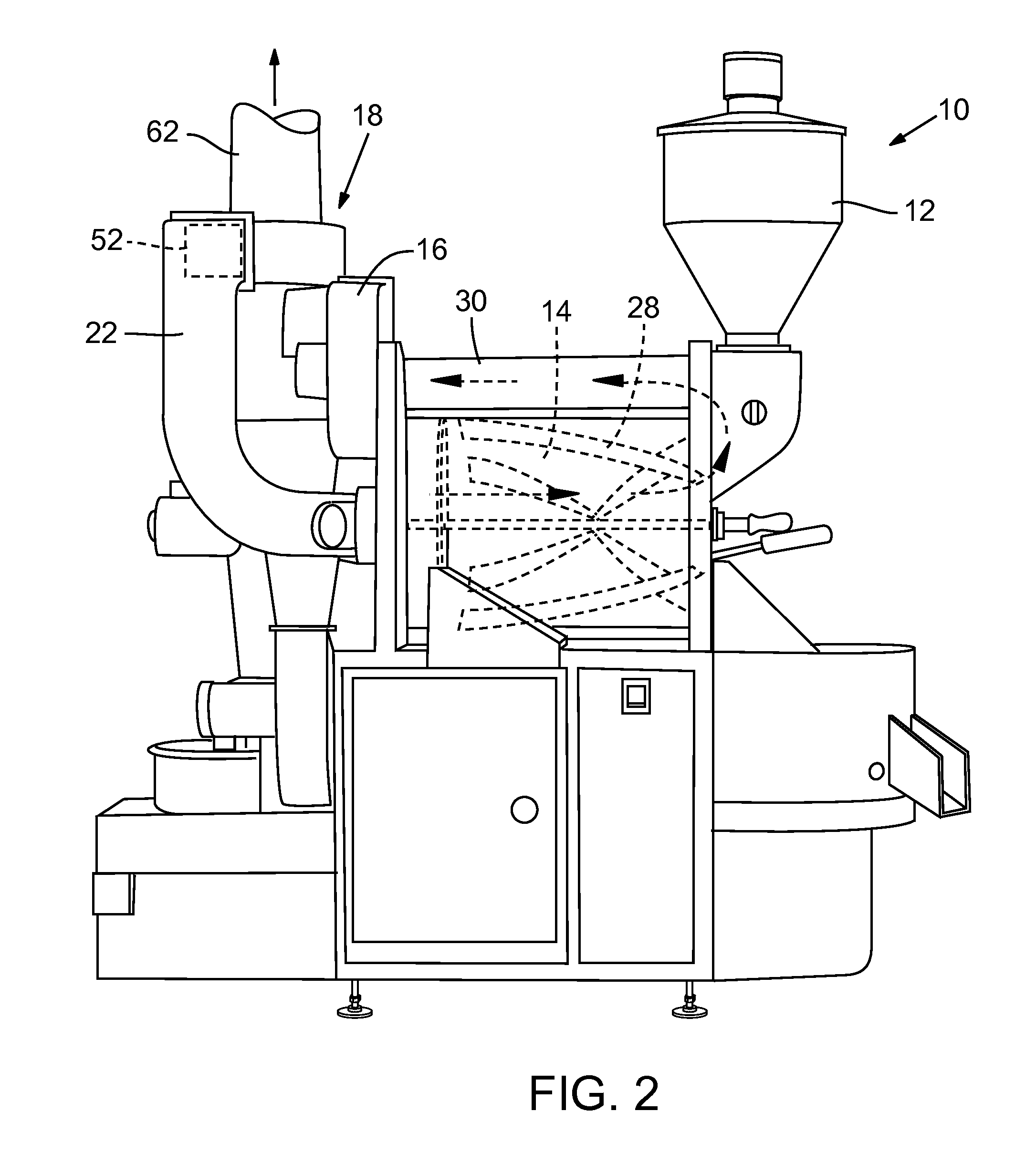

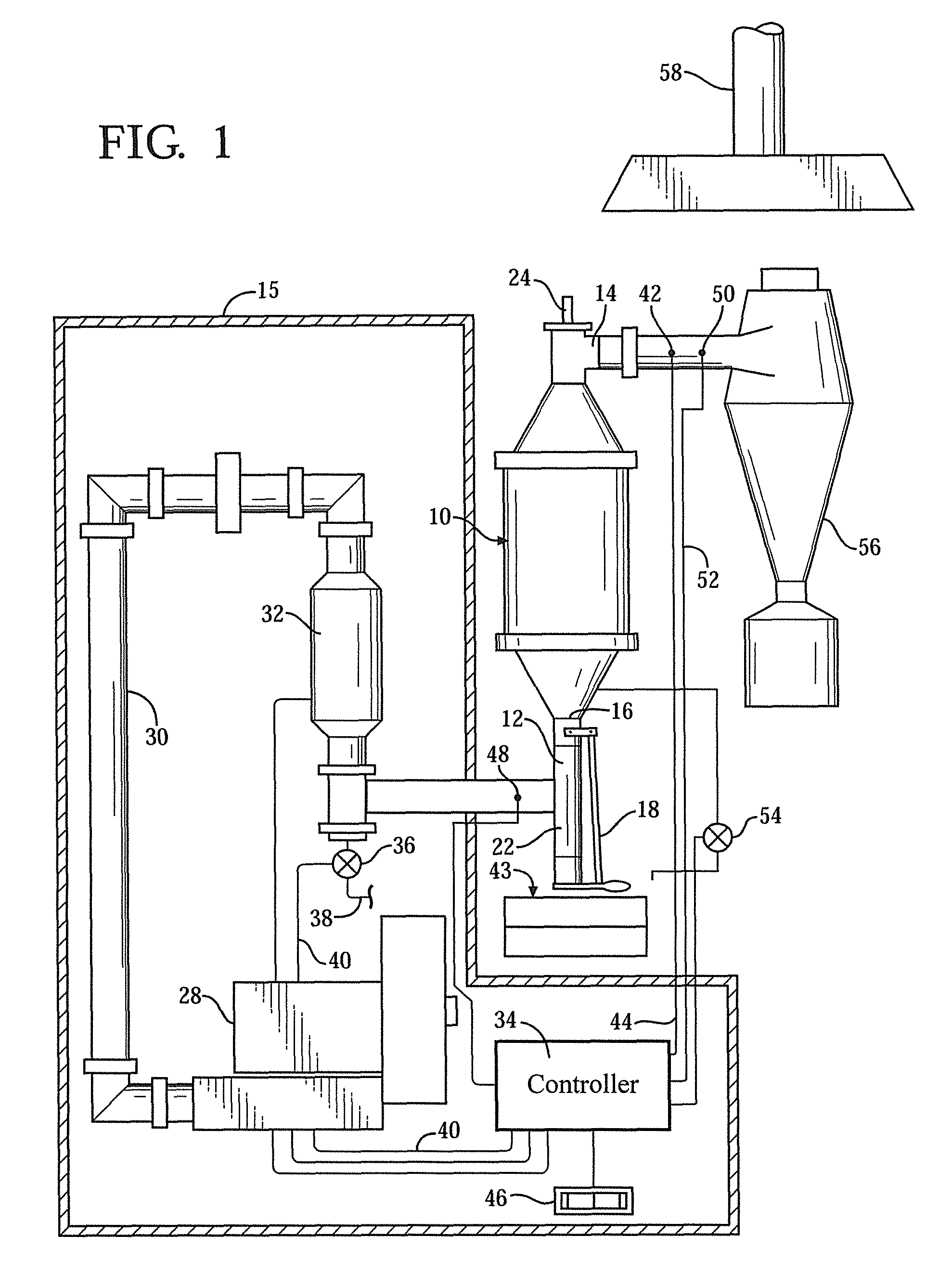

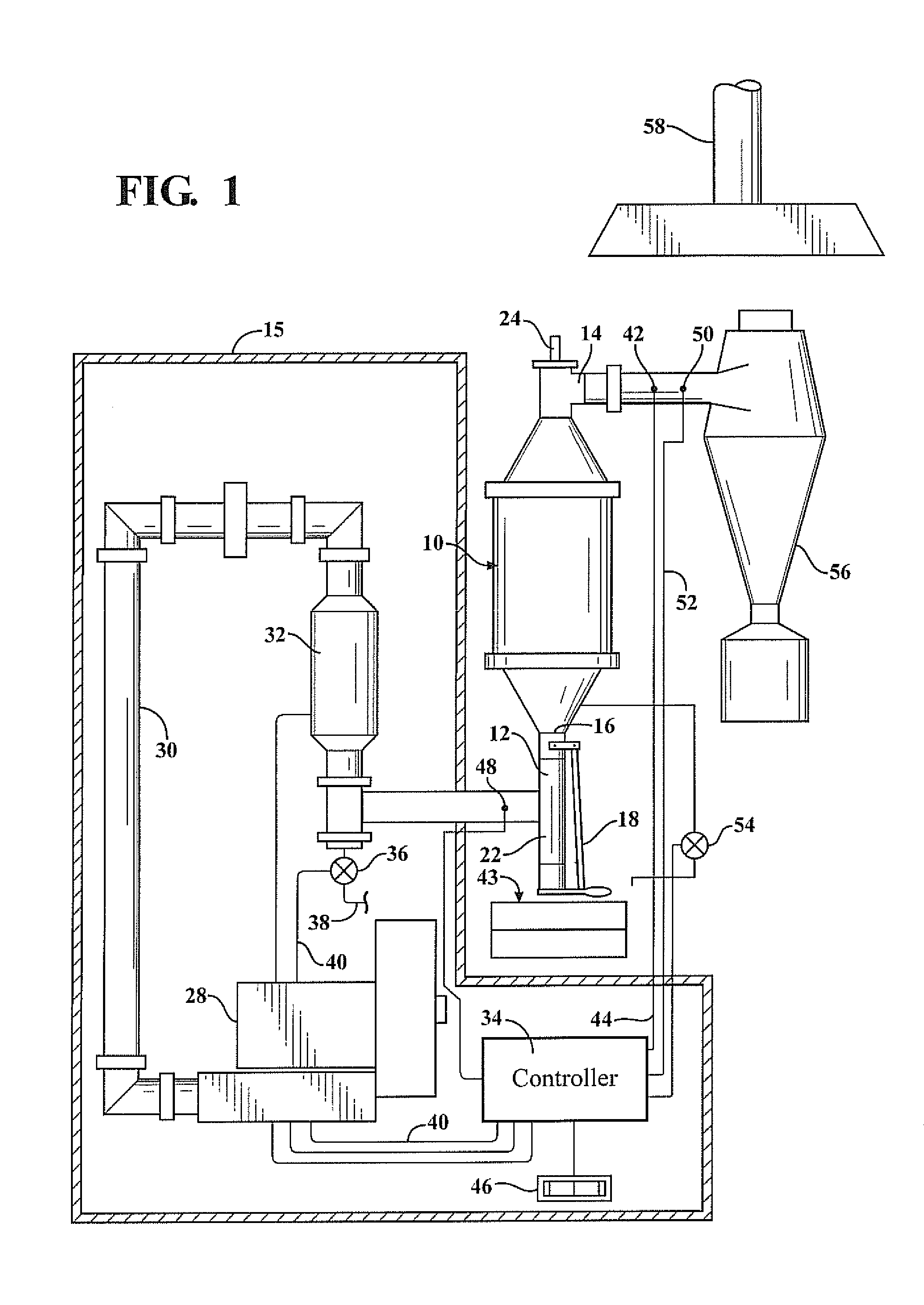

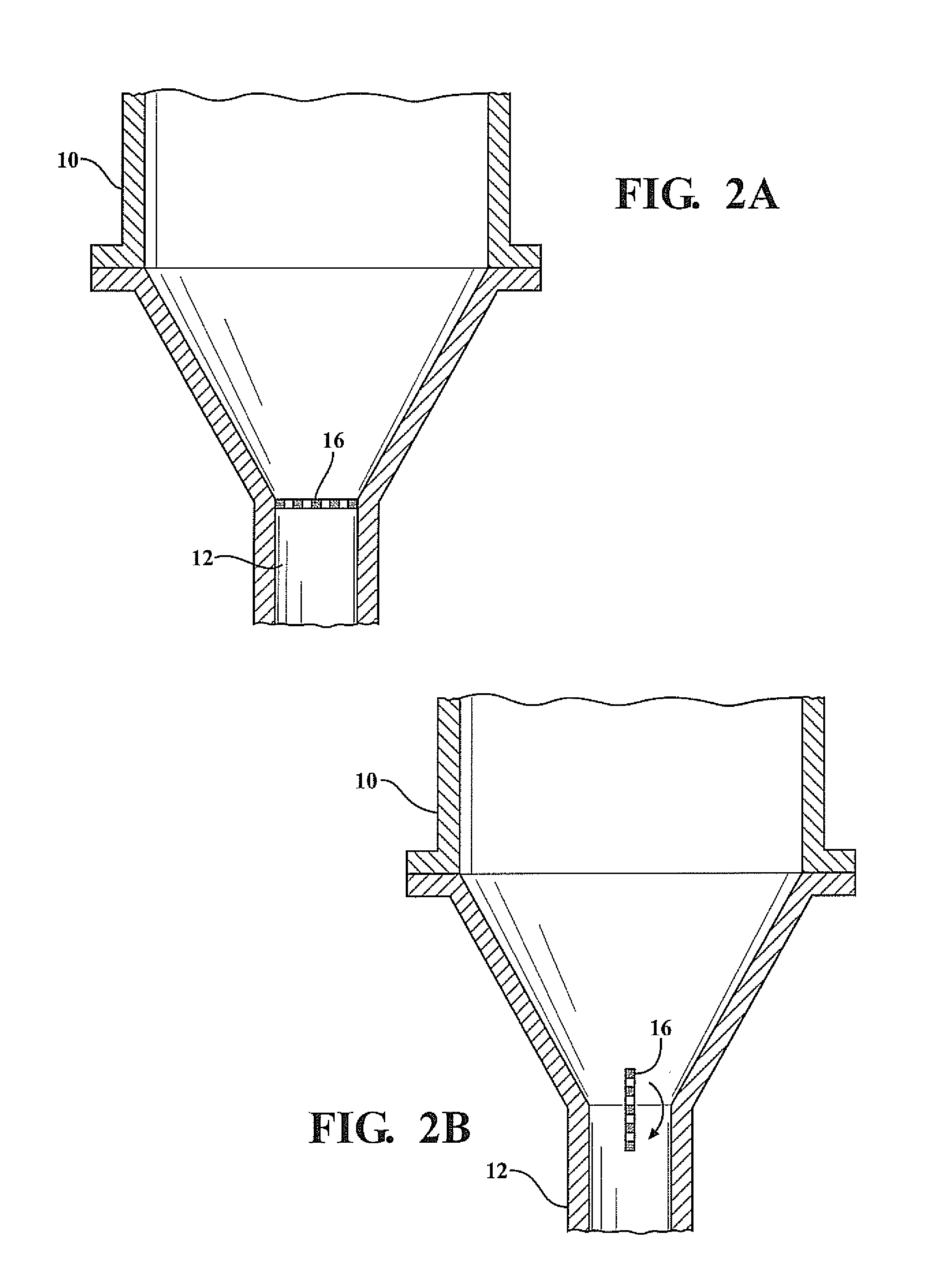

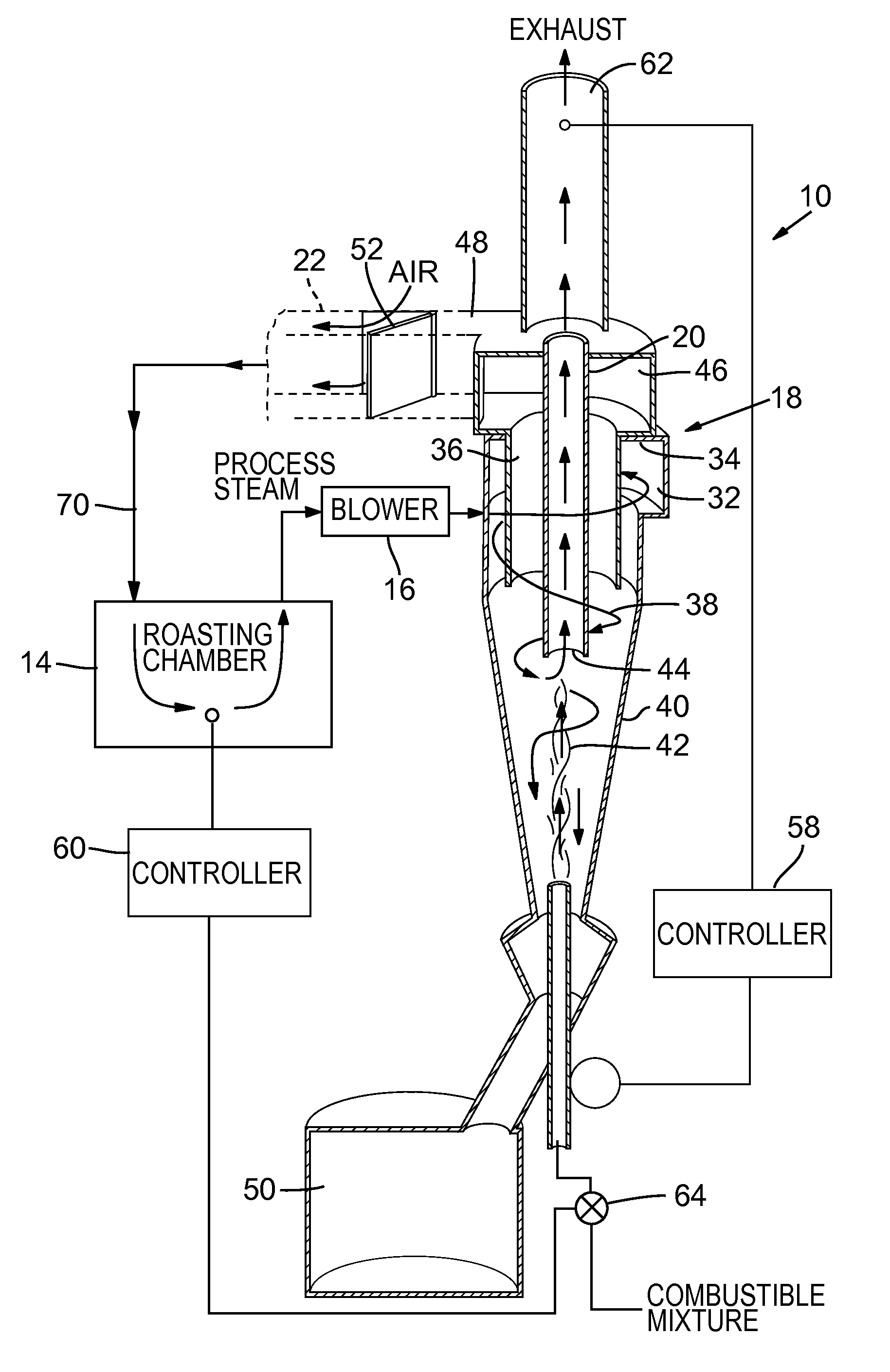

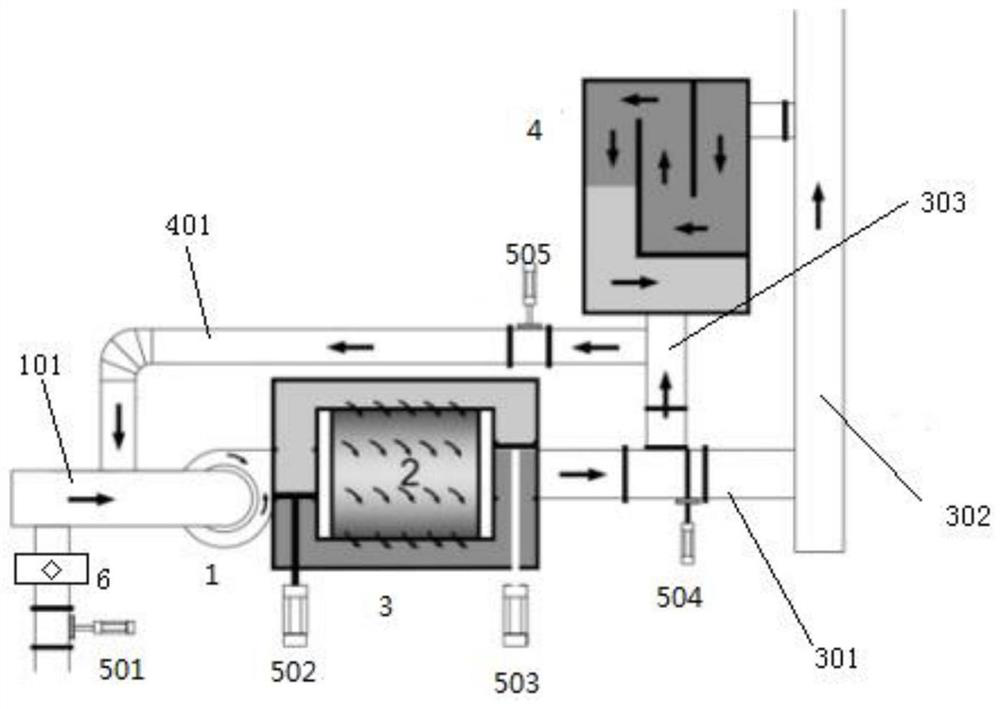

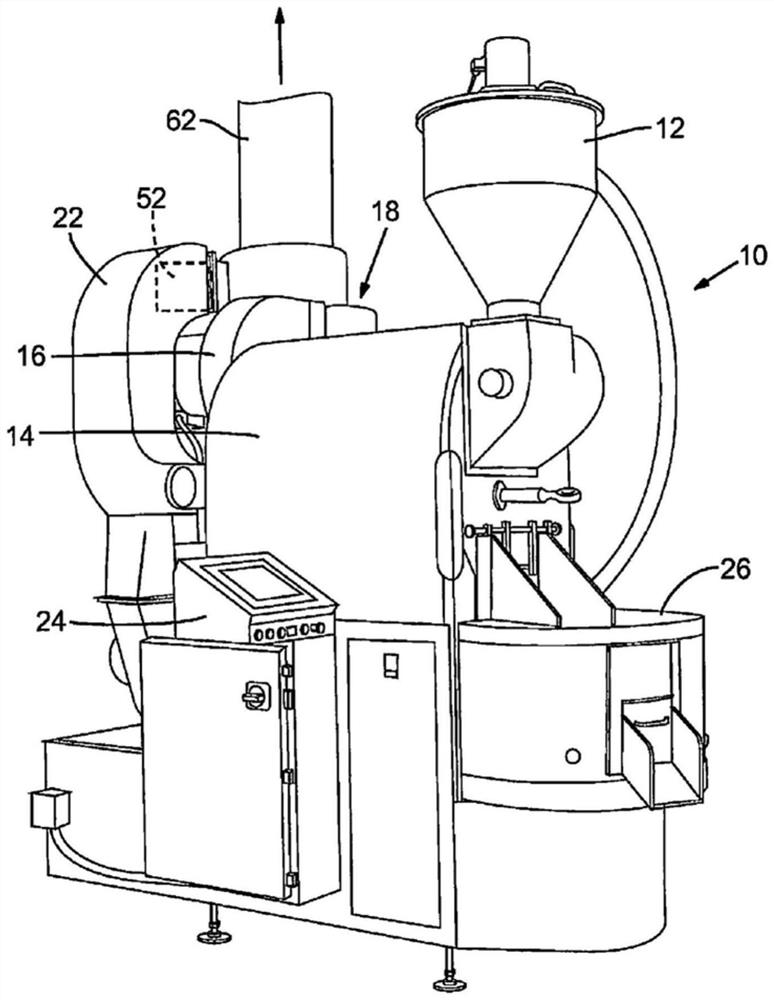

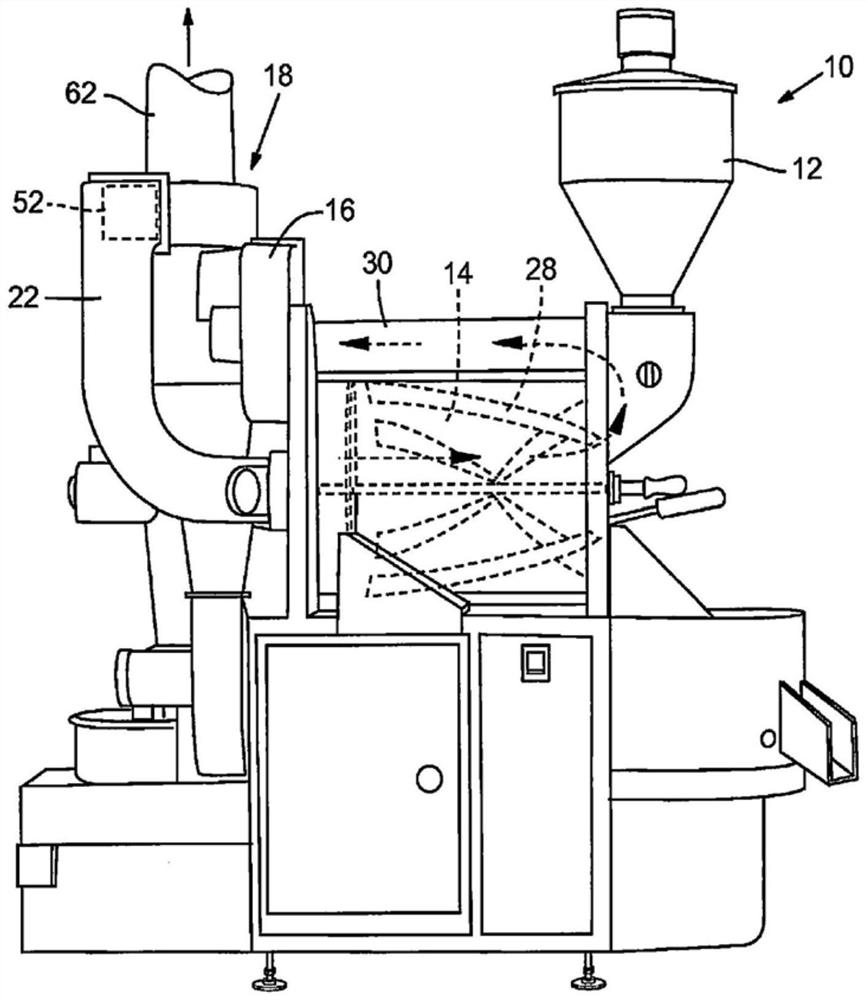

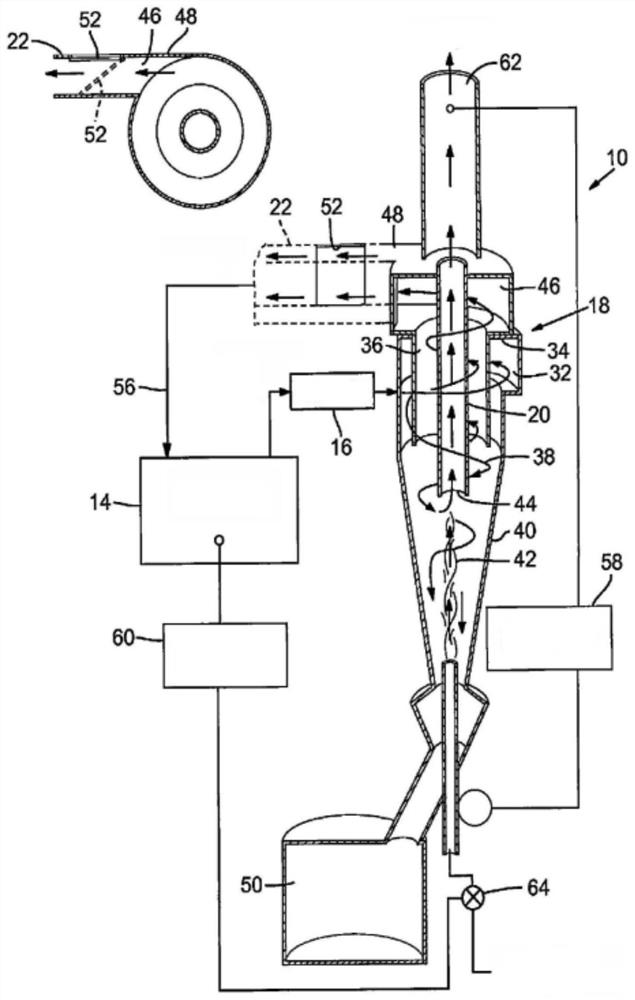

Smokeless coffee roaster

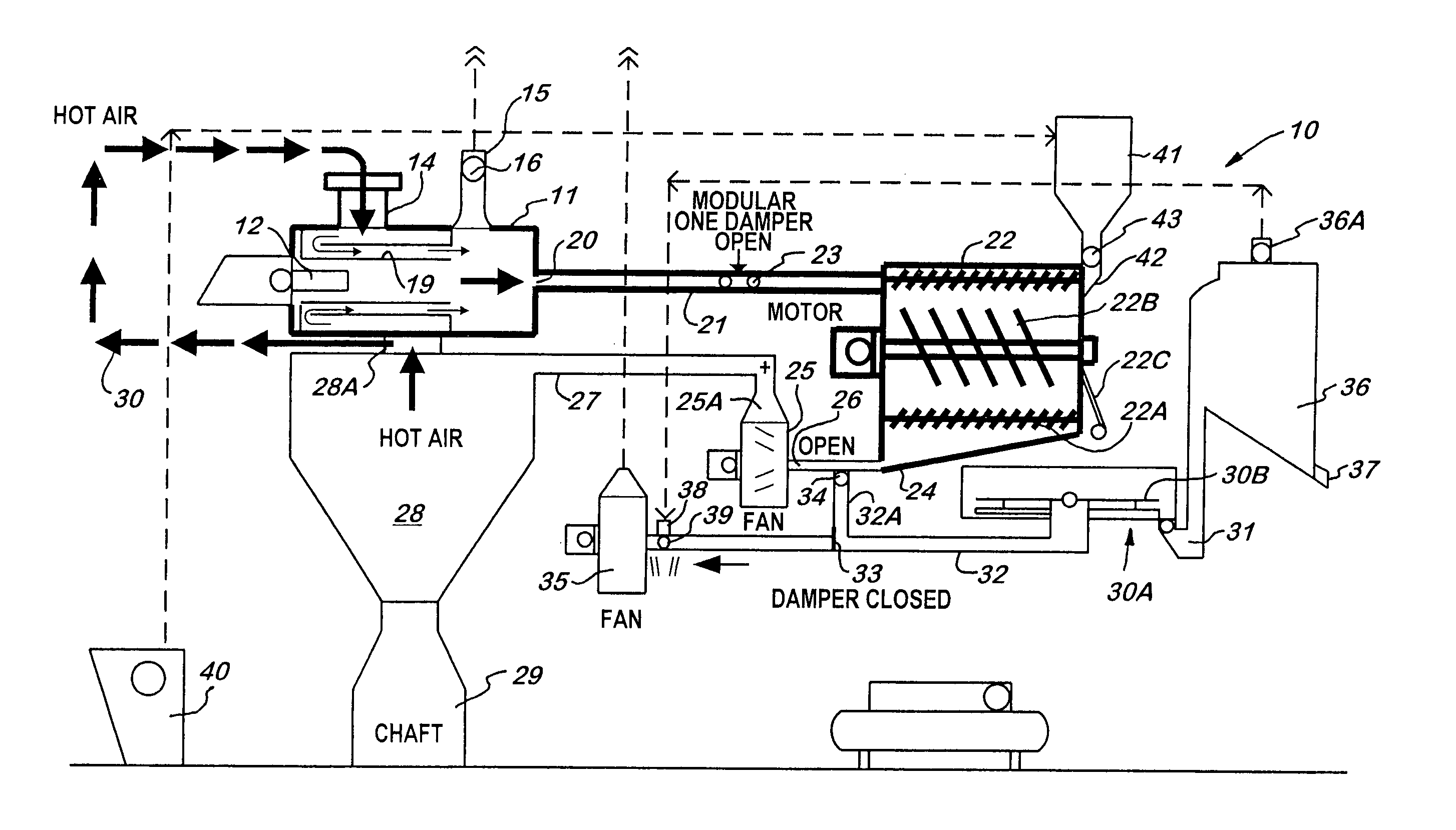

A coffee bean roasting machine of the type having a cyclone separator heating chamber and a coffee bean roasting chamber in a recirculating process stream driven by a recirculation fan is operated to air cool the roasted coffee beans in the roasting chamber, to a temperature beneath which the beans give off smoke, while at the same time incinerating smoke removed from the roasting chamber. A purge gate in ducting between the cyclone separator and the roasting chamber is opened to allow the flow of ambient air into and through the roasting chamber while blocking flow out of the cyclone separator, so that ambient air is directed through the roasting chamber. The smoke and any airborne particulate material from the roasting chamber are carried into the heating chamber and through the incineration tube, where they are incinerated. Preferably the system and process are operated automatically by a computer and programming.

Owner:LORING SMART ROAST

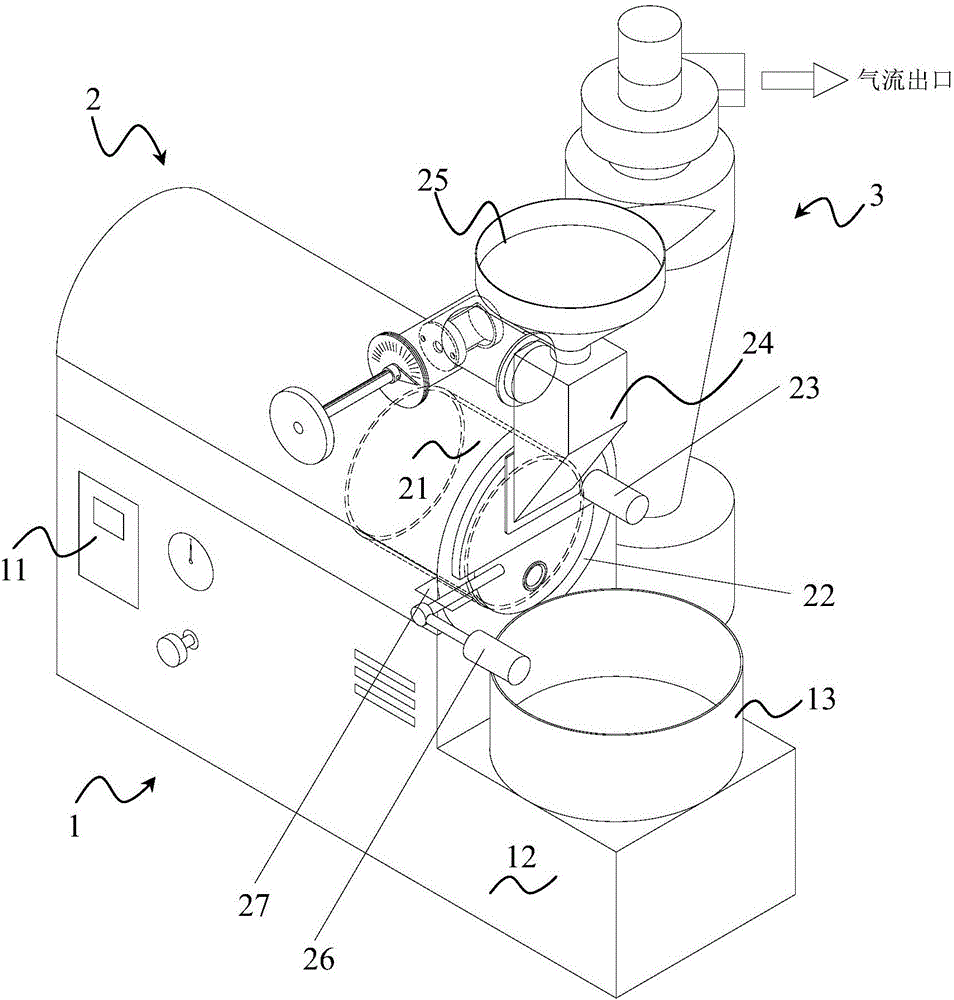

Coffee baking device capable of monitoring baking degree in real time and monitoring method

InactiveCN106579488AReal-time monitoring of baking degreeReduce labor costsFood treatmentElectricityEngineering

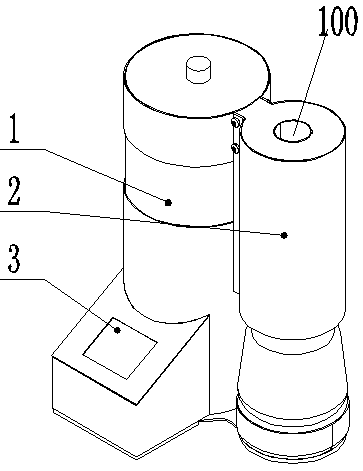

The invention discloses a coffee baking device capable of monitoring baking degree in real time and a monitoring method. The baking device includes a base, a cylinder and a control unit. The cylinder is mounted above the base. A baking chamber is arranged in the cylinder. A cover board is arranged at the joint of an open end of the baking chamber and one end of the cylinder. The cover board is provided with a monitoring device used for monitoring the baking degree of coffee beans in the baking room. The monitoring device is connected with the control unit electrically. According to the invention, real time monitoring of the baking degree of the coffee beans in the baking chamber can be realized through the monitoring device. When the coffee bean baking degree displayed on the control unit reaches a preset value, the control unit sends alarm sound or an alarm light is on, so that repeated manual observation is saved, labor strength is reduced and the working efficiency is improved at the same time.

Owner:周南

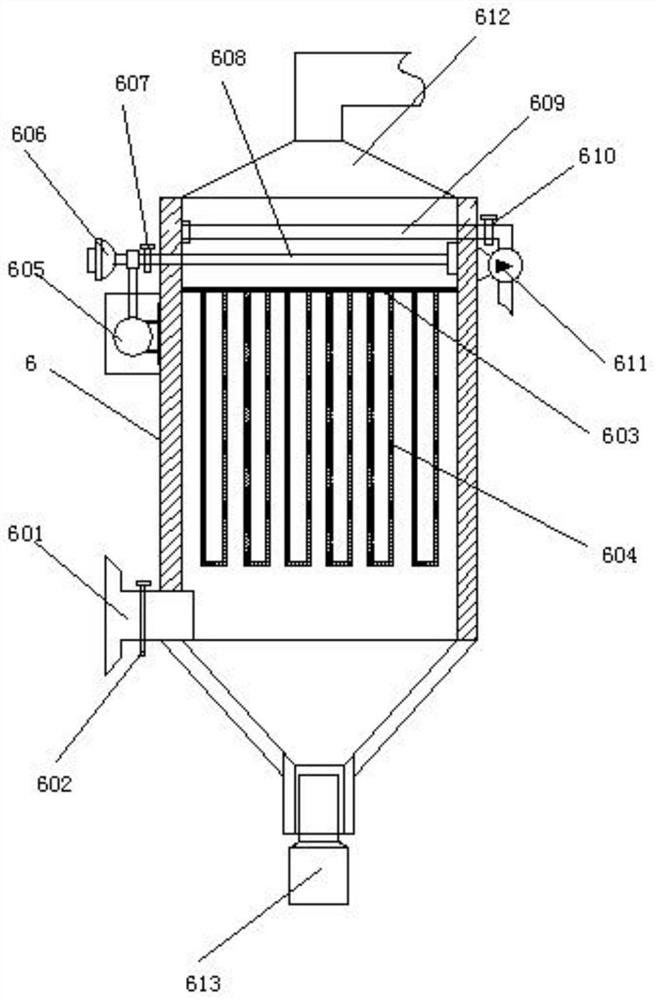

A flushing precipitator

InactiveUS20160243487A1Efficient collectionPrevent backflowVortex flow apparatusUsing liquid separation agentWater flowWater spray

A dust collector separates dust from the gas including the dust such as smoke discharged from a coffee roasting machine. The dust collector uses a water spray. The dust collector can prevent blockage of nozzles of a upper water supply line and a side water supply line by arranging the upper nozzle and the side nozzle, which spray water, to be faced to each other within the body of the dust collector. Water flows along the side within the inlet which is slant downward, which allows the gas to flow into the body of the dust collector, and a separate assistant water supply line is connected to the inlet.

Owner:CECUBE

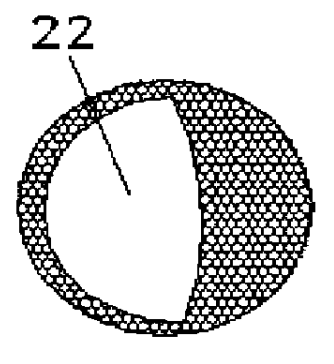

Coffee roaster filter, chaff collector and smoke reducer

InactiveUS6065226ASimple methodAvoid pollutionMilk preservationMeasurement devicesParticulatesMicroparticle

An exhaust particle and particulate containment system for a coffee roaster comprises a filter chamber for exhaust coffee roasting by-products including chaff and smoke particulates and oils is comprised of a screen for separating chaff from the exhaust coffee roasting by-product effluent and a filter for containing chaff and removing smoke particulates and oils when the screen is in a closed position.

Owner:GELL JR HAROLD A

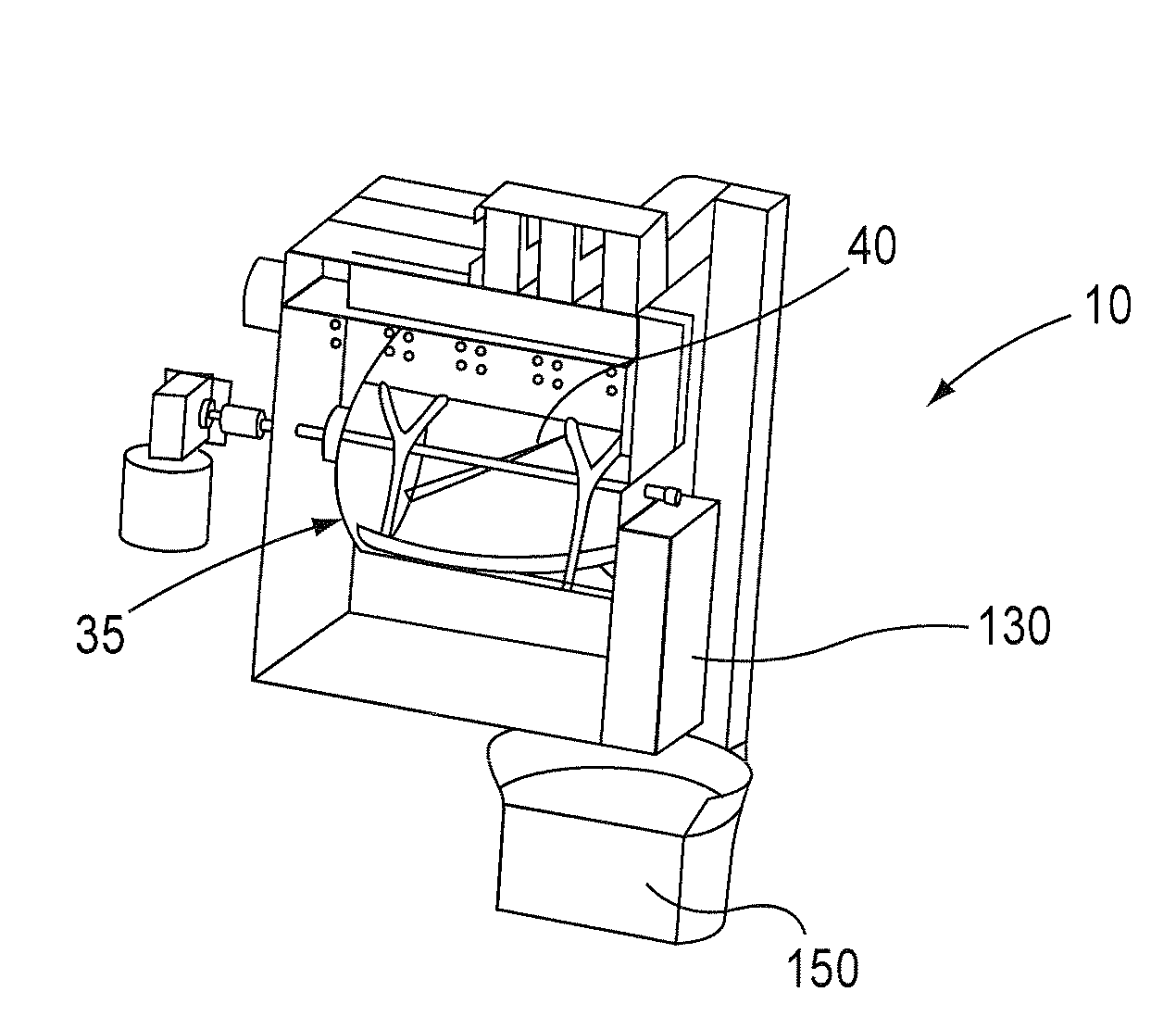

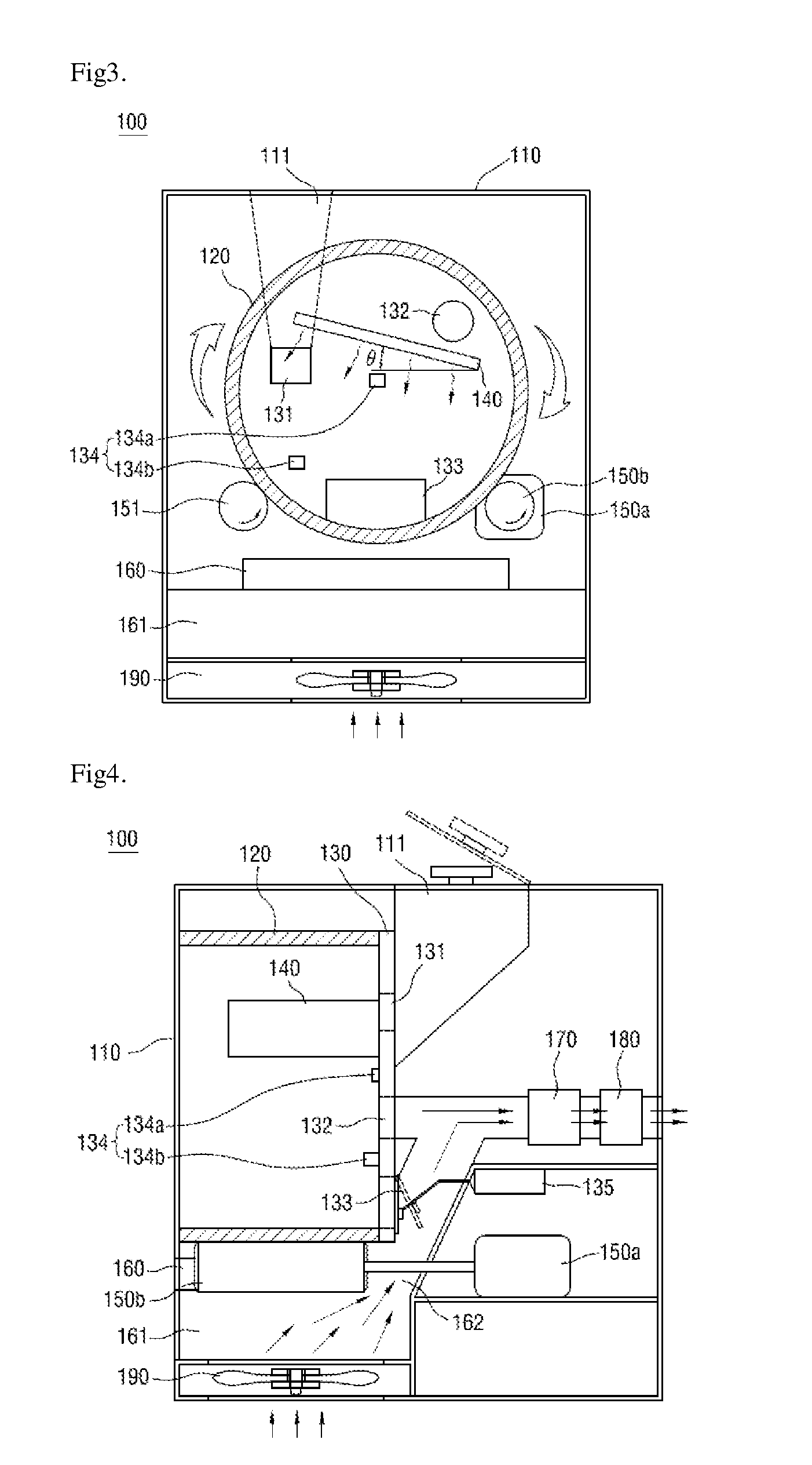

Coffee roaster

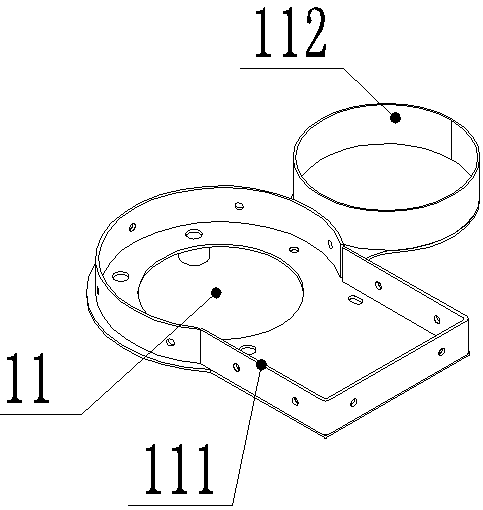

ActiveUS20160183586A1Easy to control temperatureAccurate operationCooking vesselsCoffee roasting methodsMechanical engineeringCoffee roaster

The present invention relates to a coffee roaster comprising: a housing; a supporting plate located within the housing, the supporting plate comprising a heating means in a predetermined region; a drum chamber located at one side of the supporting plate within the housing; a first supporting unit for supporting the drum chamber, the first supporting unit being installed to be adjacent to the outer circumferential surface of the drum chamber; and a second supporting unit for supporting the drum chamber, the second supporting unit being installed to be adjacent to the outer circumferential surface of the drum chamber and being spaced apart from the first supporting unit by a predetermined distance. As the drum chamber is rotated by receiving a driving force for rotation from the first supporting unit, the drum chamber can be rotated without being obstructed by the heating means.

Owner:CM TECH CO LTD

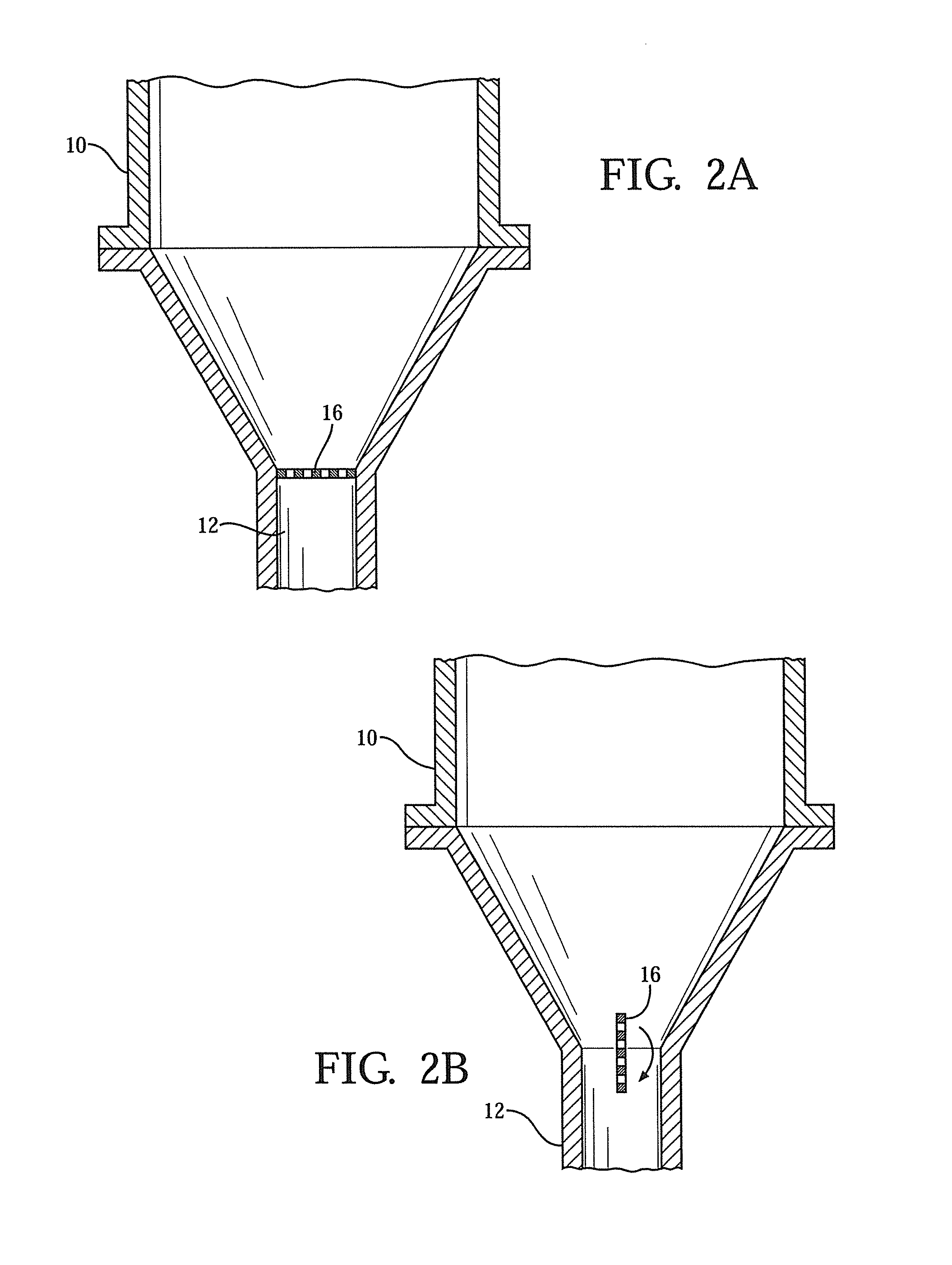

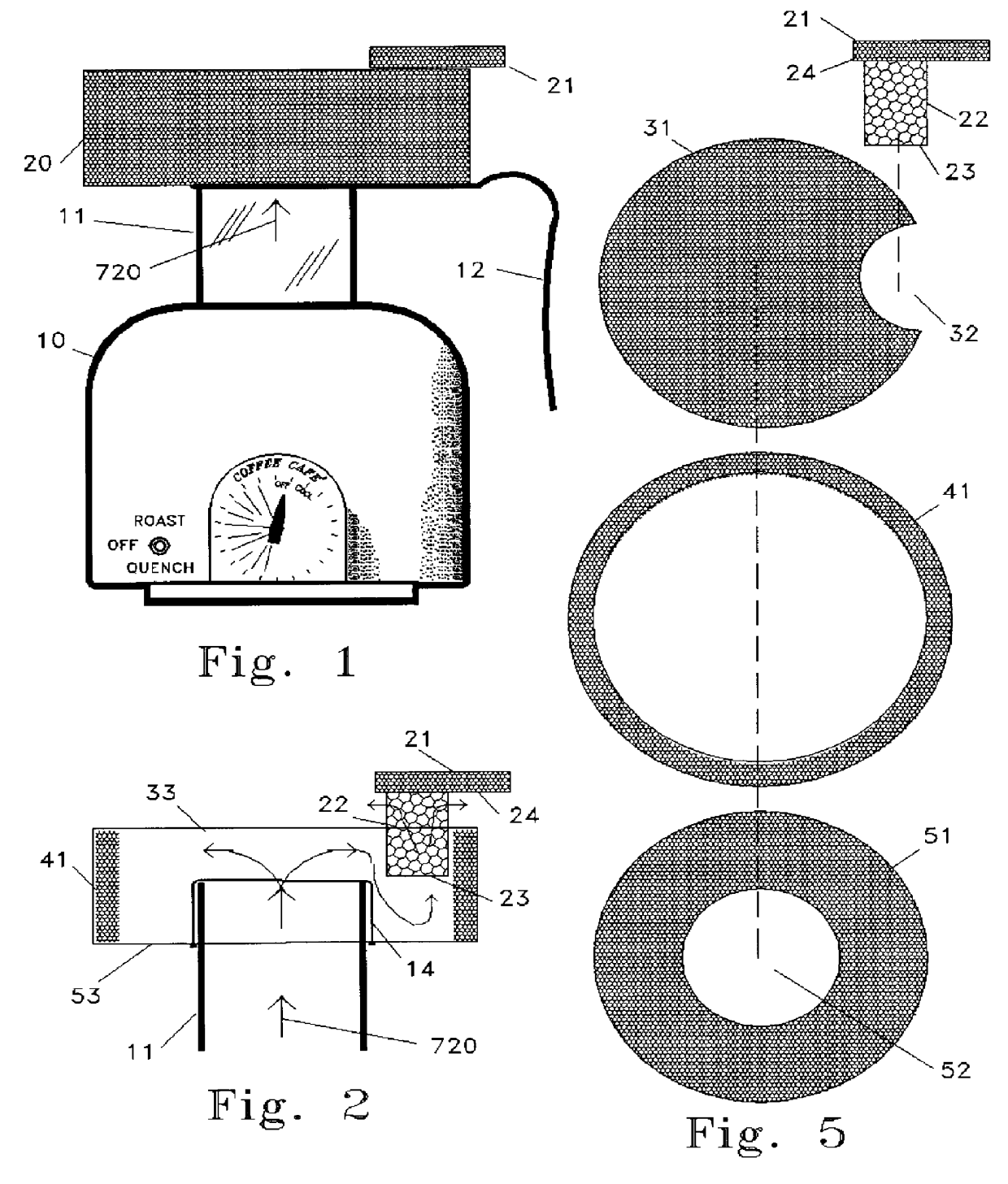

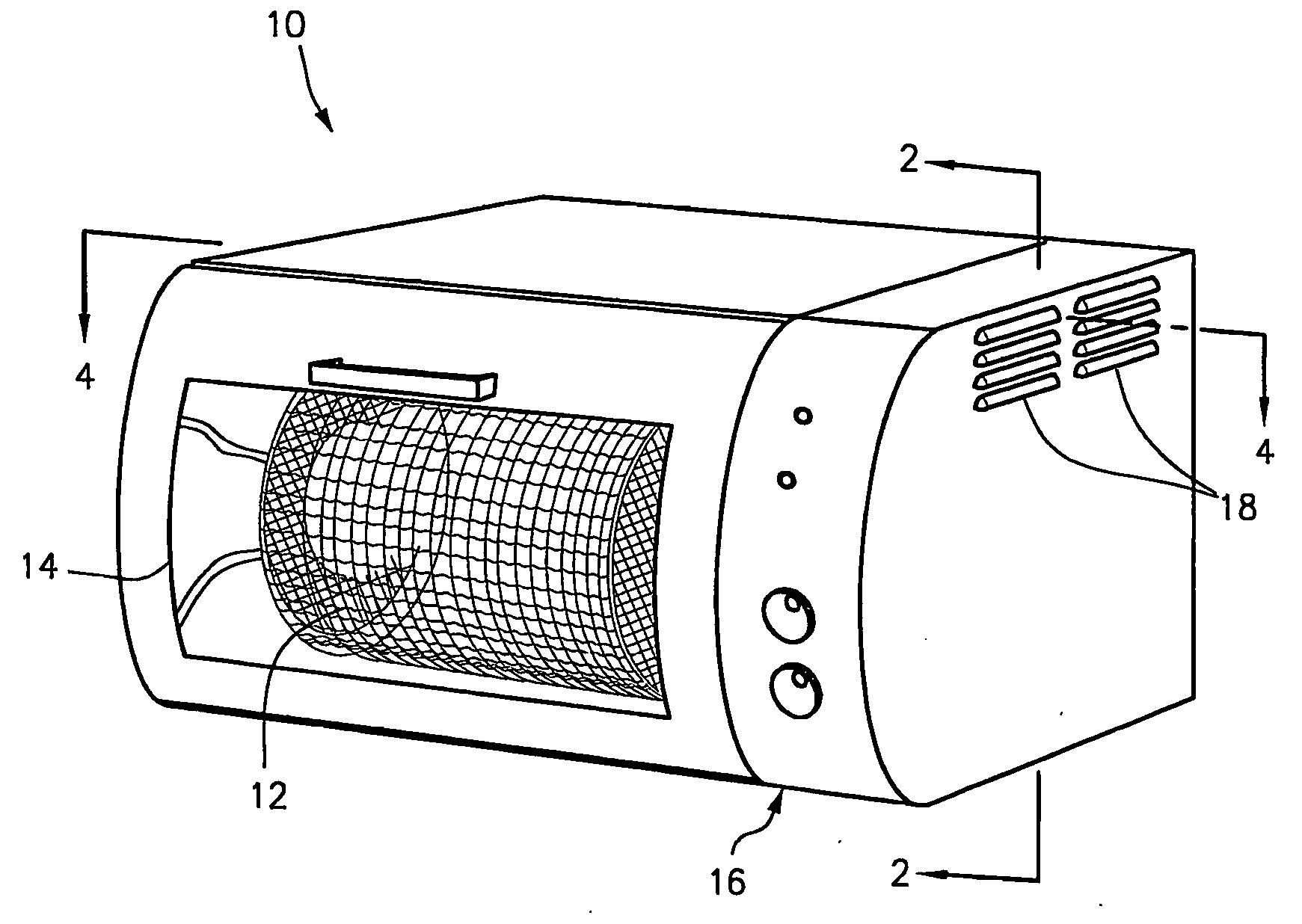

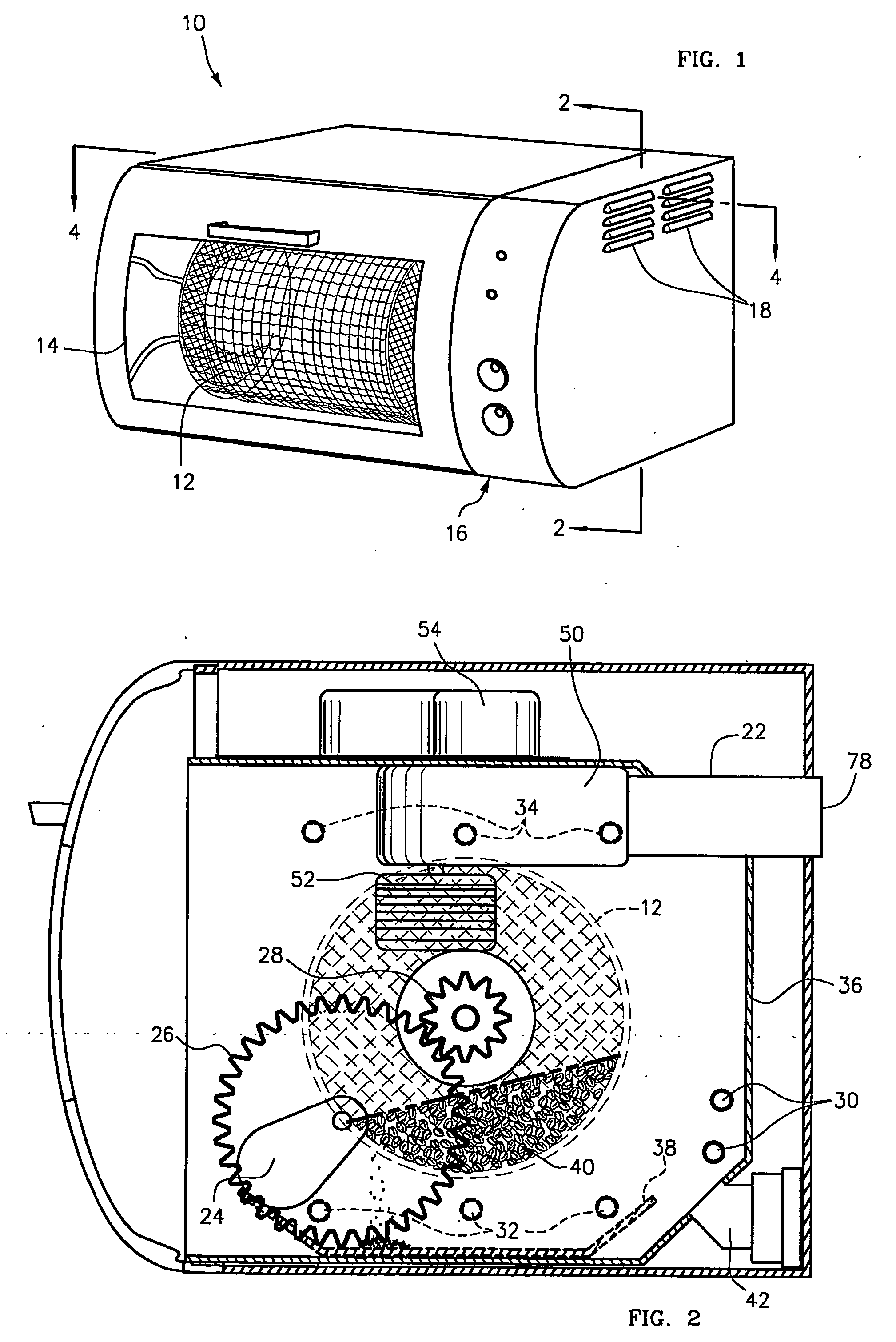

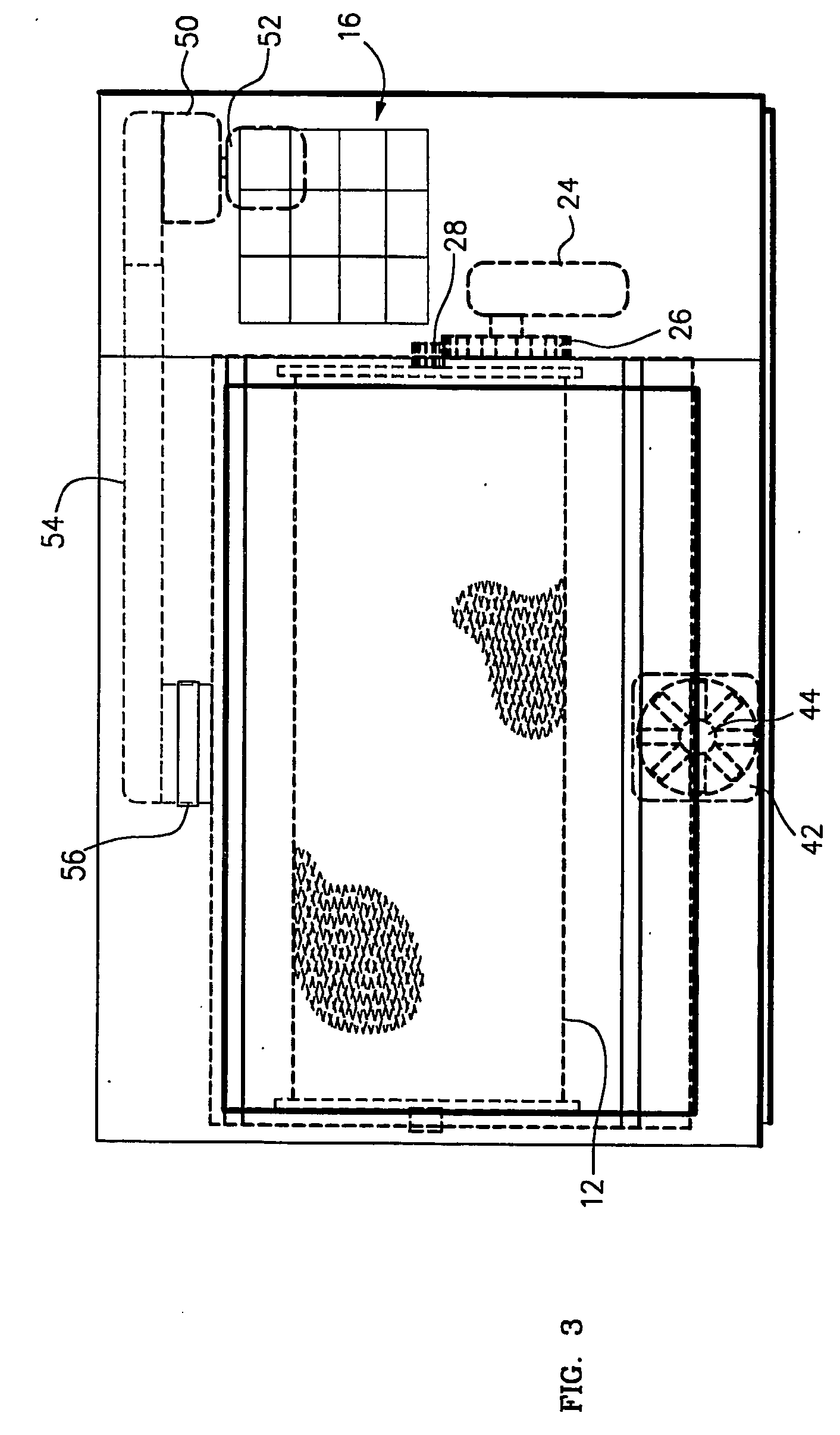

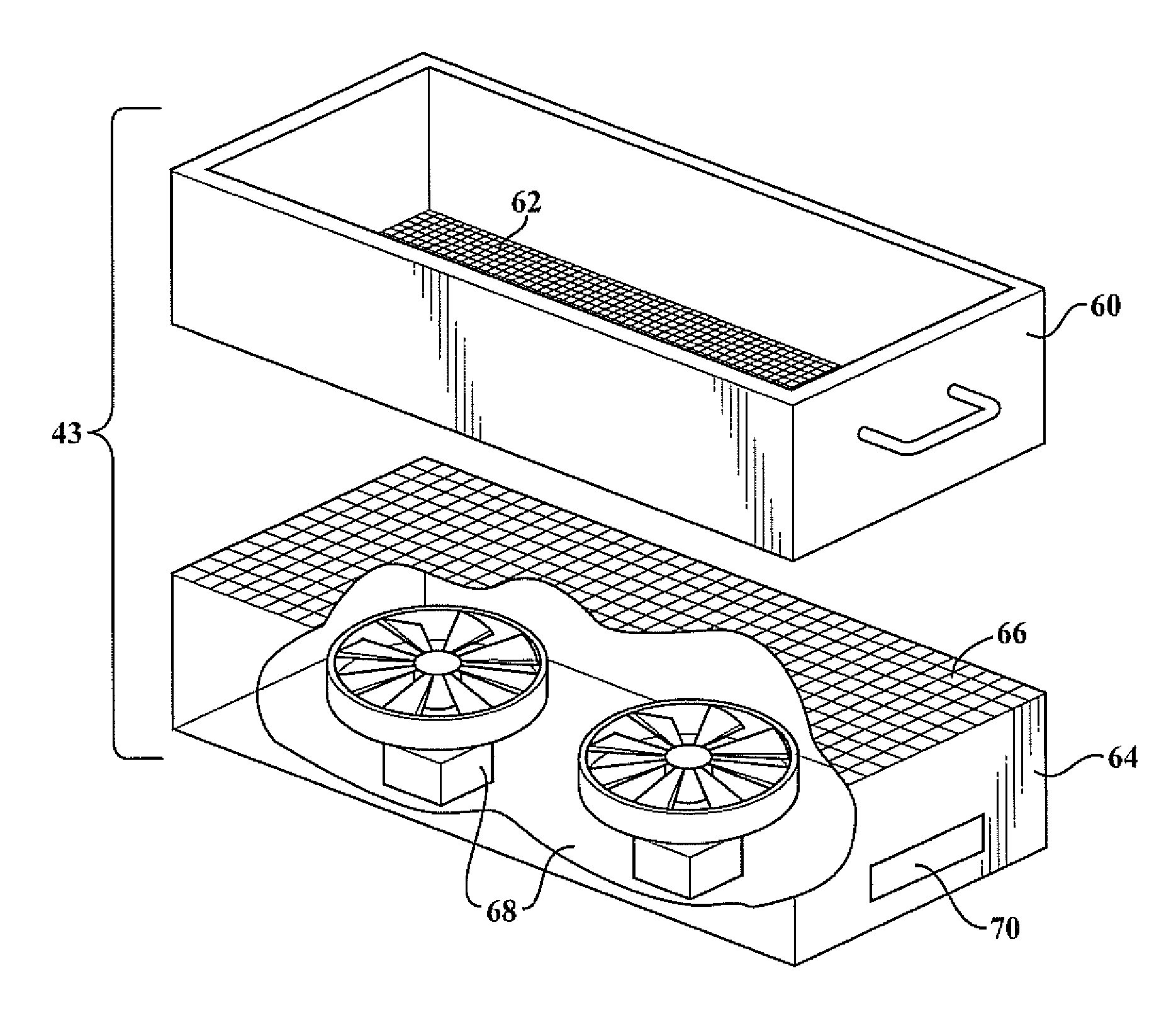

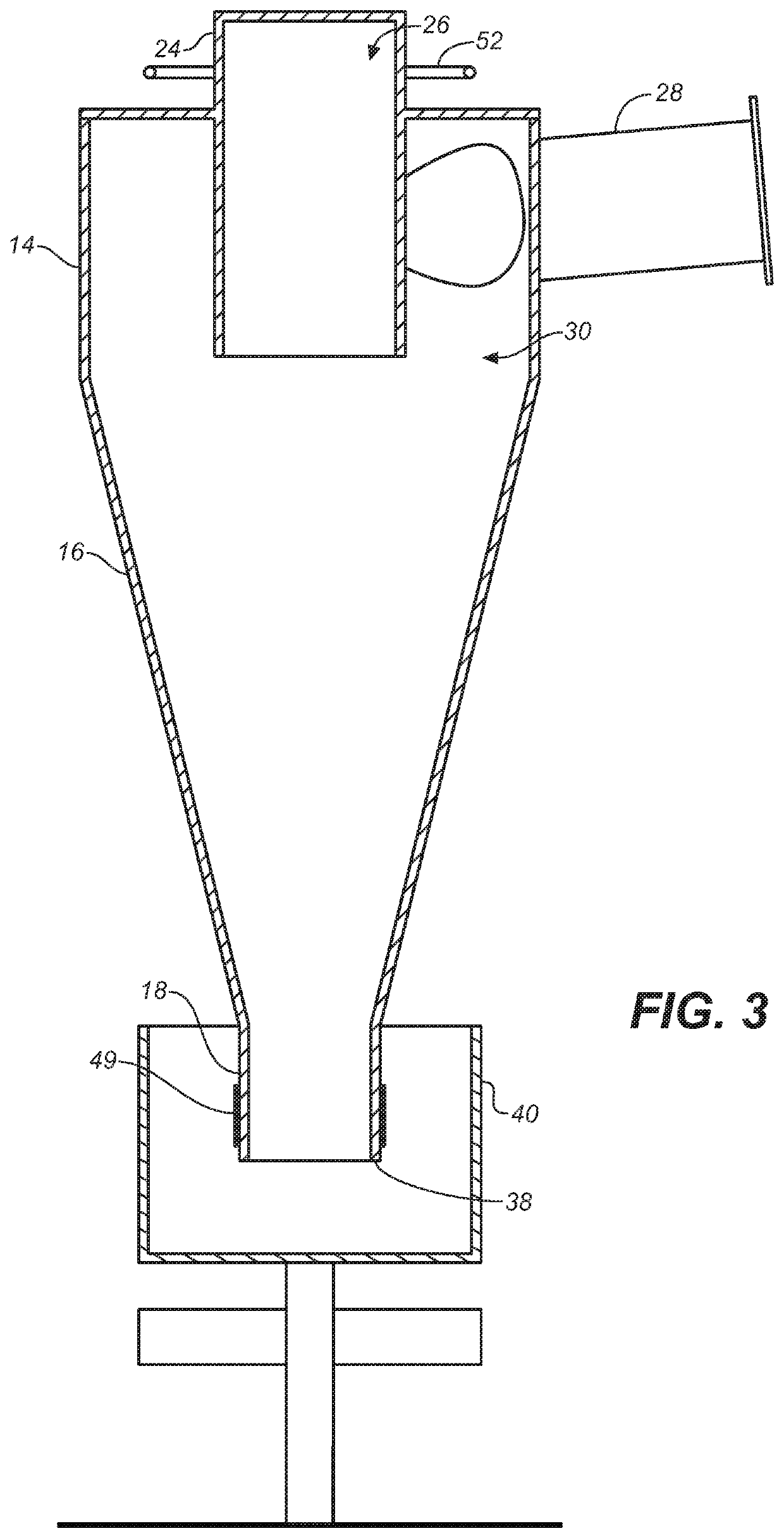

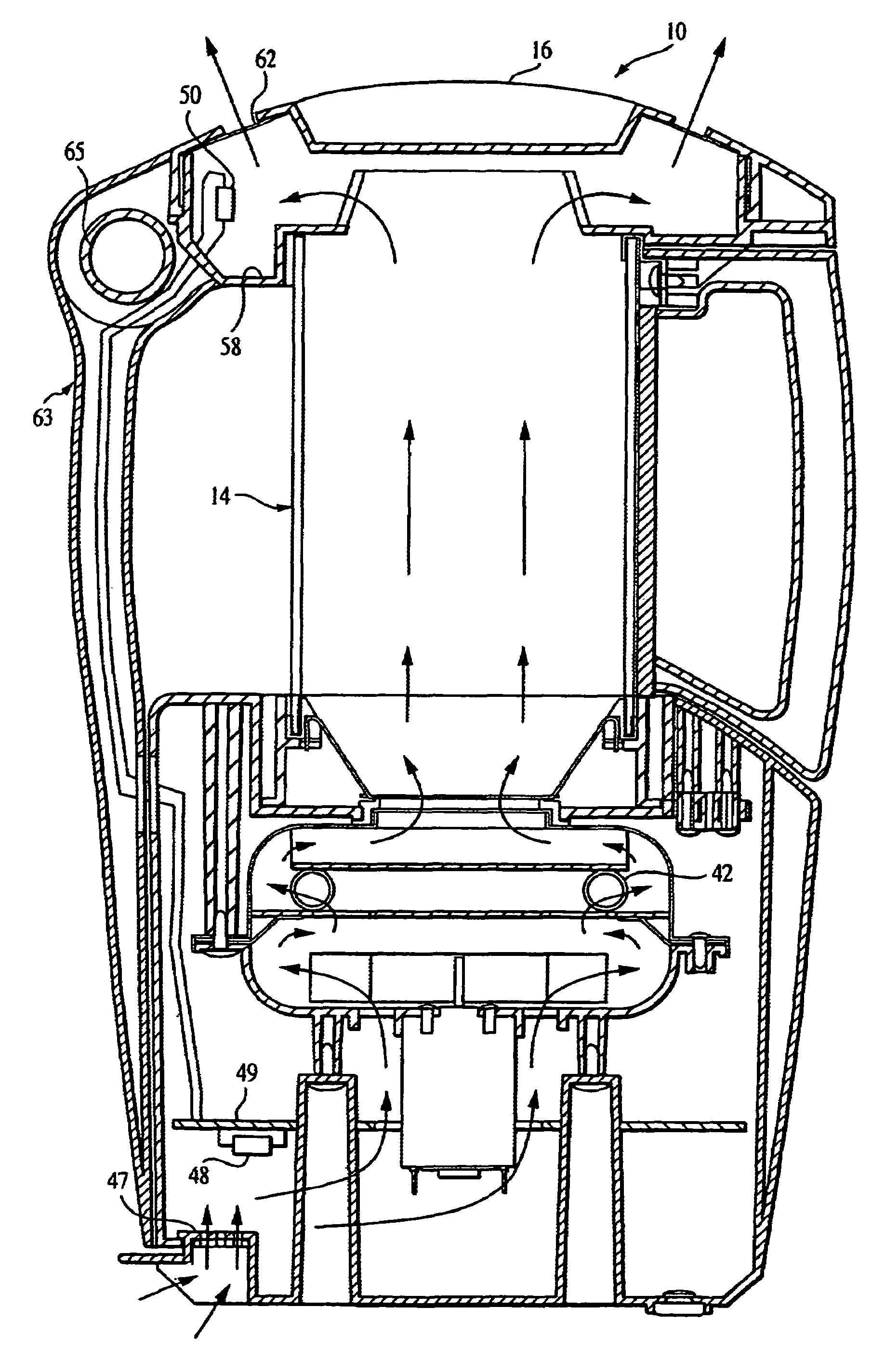

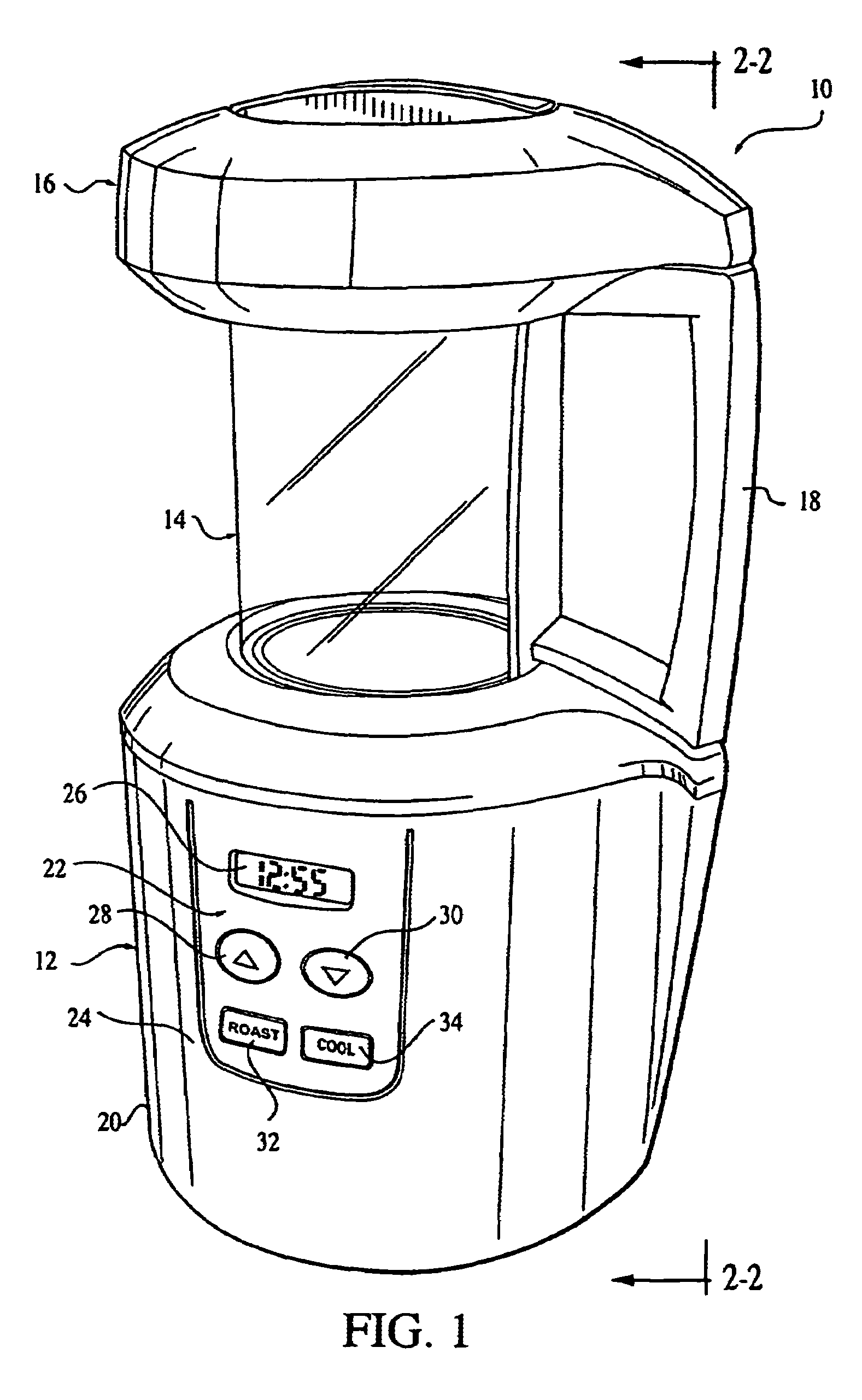

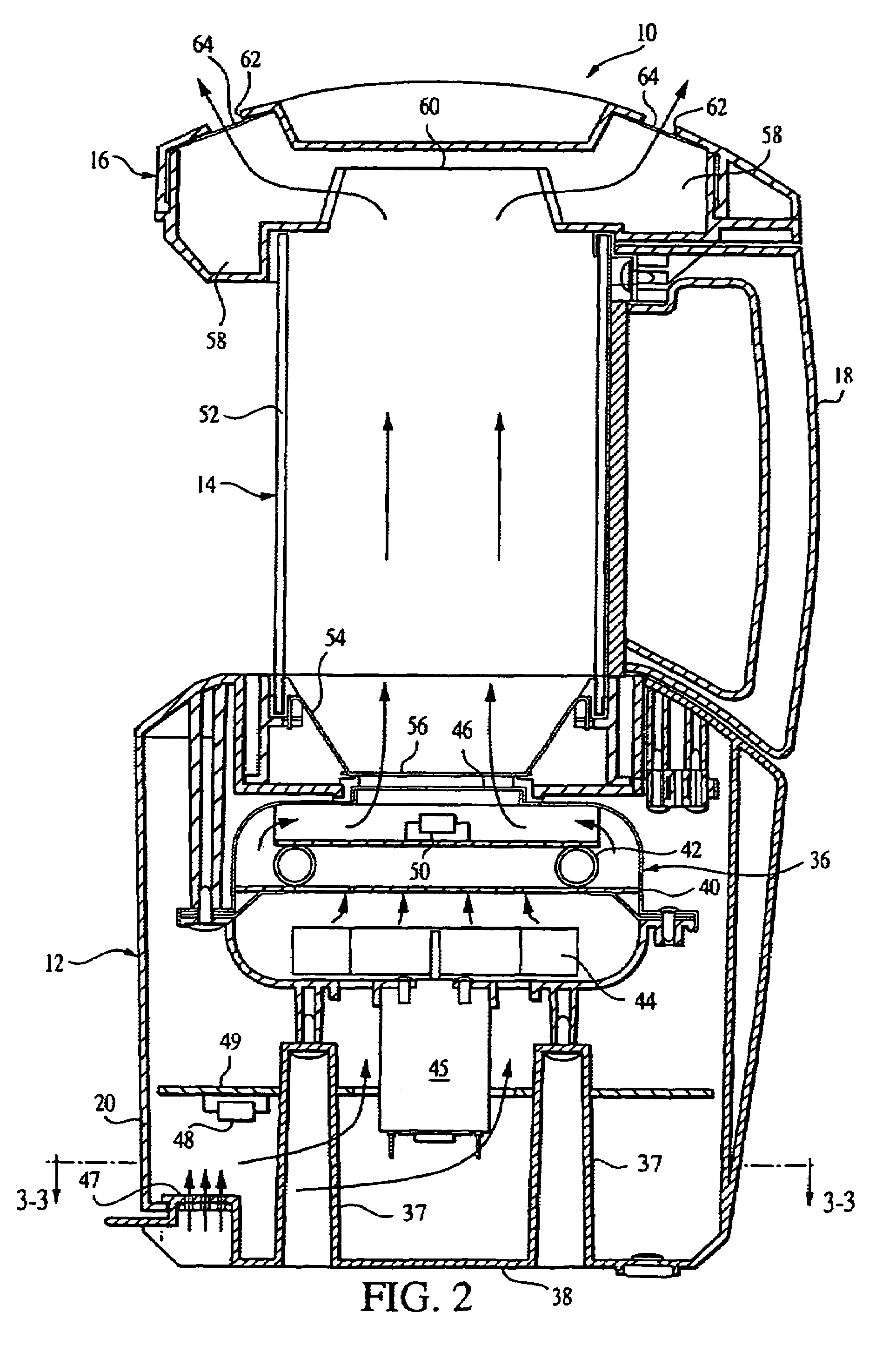

Small-batch coffee bean roaster and counter-top oven appliance

InactiveUS20050072018A1Efficient and economical wayLow costRotary drum furnacesBaking ovenEngineeringCoffee roaster

A countertop appliance and coffee roaster (10) with a roasting chamber containing at least one heating element (30), a bean container (12), and an exhaust duct (22) for venting said roasting chamber. The countertop appliance and coffee roaster (10) may include a cooling duct (42) for cooling the beans at the conclusion of the roasting cycle. The exhaust duct (22) may contain an exhaust fan (72), secondary heating elements (74), and / or exhaust duct vents (20).

Owner:BEHM JOSEPH

Coffee roasting machine

InactiveCN105935249AImplement automatic cleanupRealize the collectionBeverage vesselsFood treatmentDrive motorEngineering

The invention relates to a coffee roasting machine which comprises a head cover, a rack, a roasting heater, a roasting container and a bean shell storing container. The roasting container and the bean shell storing container are detachably arranged on the rack, the roasting container comprises a container body and a stirring component, the roasting heater is connected with the container body, the stirring component is used for being connected with a drive motor and rotatably arranged in the container body, the container body is provided with an opening, the head cover movably covers the opening of the container body, the end, far away from the opening, of the container body is provided with multiple material discharging channels, and the bean shell storing container is arranged at the end, provided with the material discharging channels, of the container body. When the roasting heater conducts heating to roast coffee beans in the roasting container, the coffee beans are rotated by means of the stirring component, bean shells and coffee beans are separated, the separated bean shells drop into the bean shell storing container though the material discharging channels, automatic cleaning and collecting of the bean shells in the roasting process are achieved, and therefore the roasting efficiency is improved.

Owner:洪英玉

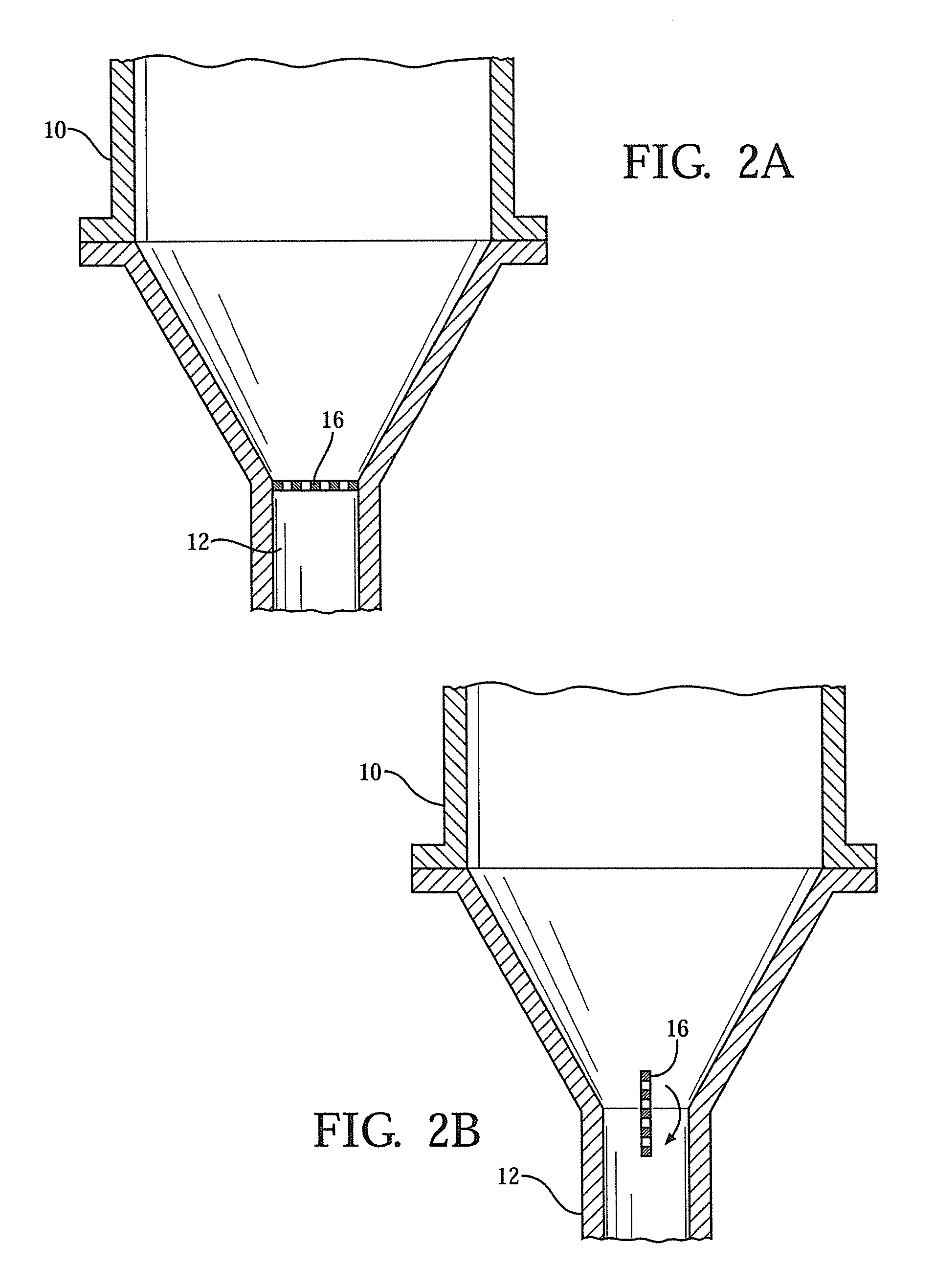

Fluidized bed coffee roaster

A fluidized bed coffee roaster controls air flow and / or temperature to maintain a desired time-temperature roast profile. The roaster may also provide a two stage quenching cycle for rapidly cooling roasted coffee beans to ambient temperature. In a first stage of the quenching cycle unheated air is passed through the roasted beans while they are still in the roasting chamber of the fluidized bed roaster. In a second stage of the quenching cycle which is carried out outside of the roasting chamber, in a fluidized bed quenching station, unheated air is flowed through, and fluidizes, the roasted coffee beans cooling them to ambient temperature.

Owner:JAVA MASTER INT LLC

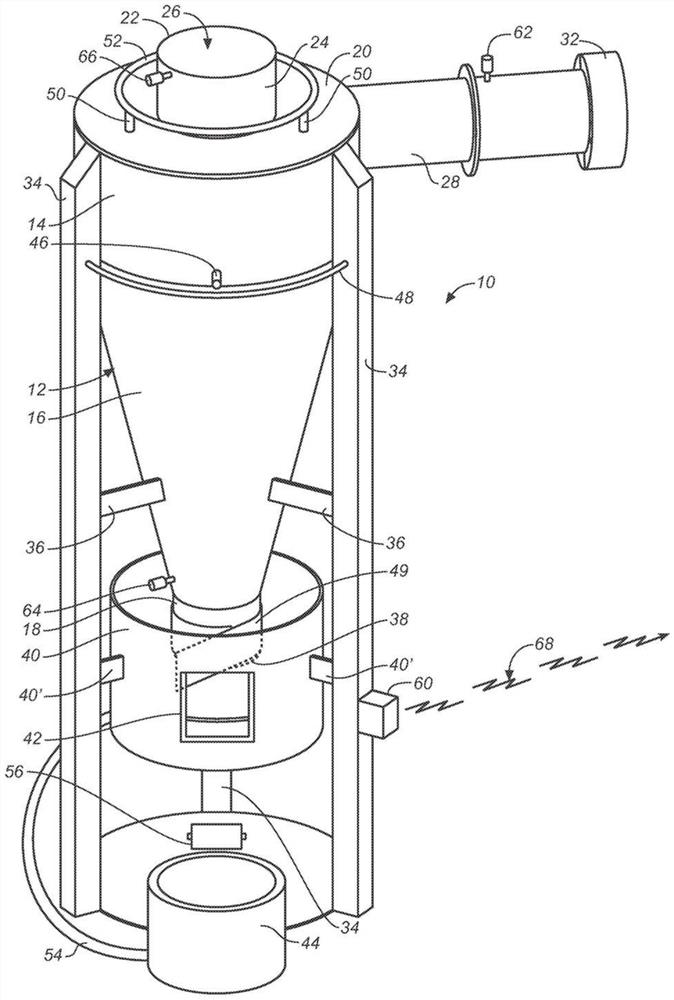

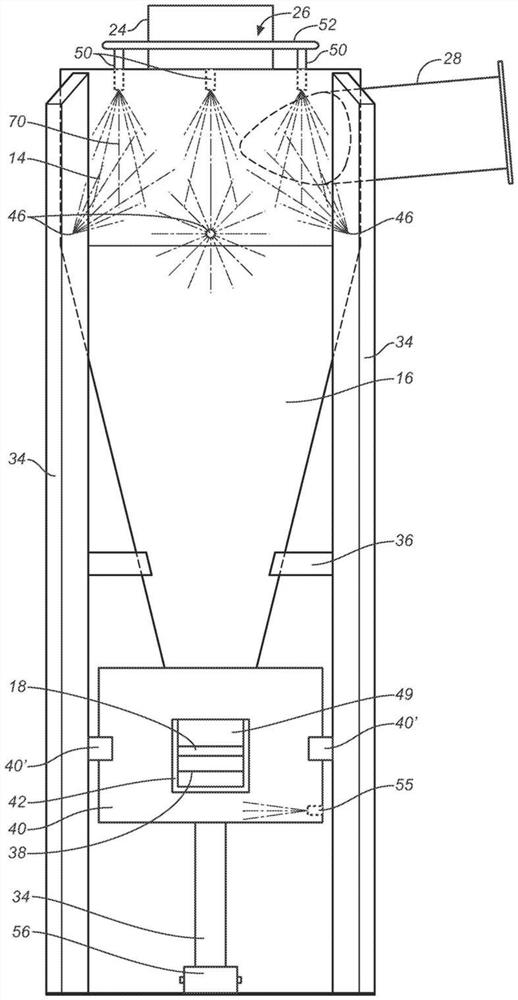

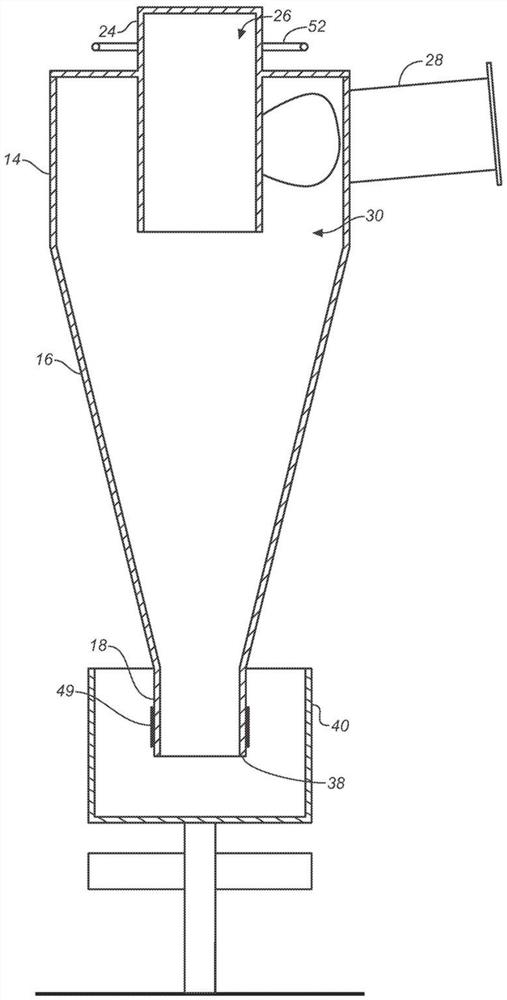

Fluidized bed coffee roaster having dual-stage quenching cycle

A fluidized bed coffee roaster provides a two stage quenching cycle for rapidly cooling roasted coffee beans to ambient temperature. In a first stage of the quenching cycle unheated air is passed through the roasted beans while they are still in the roasting chamber of the fluidized bed roaster. In a second stage of the quenching cycle which is carried out outside of the roasting chamber, in a fluidized bed quenching station, unheated air is flowed through, and fluidizes, the roasted coffee beans cooling the to ambient temperature.

Owner:JAVA MASTER INT LLC

Temperature Controlled Exhaust Steam Water Filter for Coffee Roasters

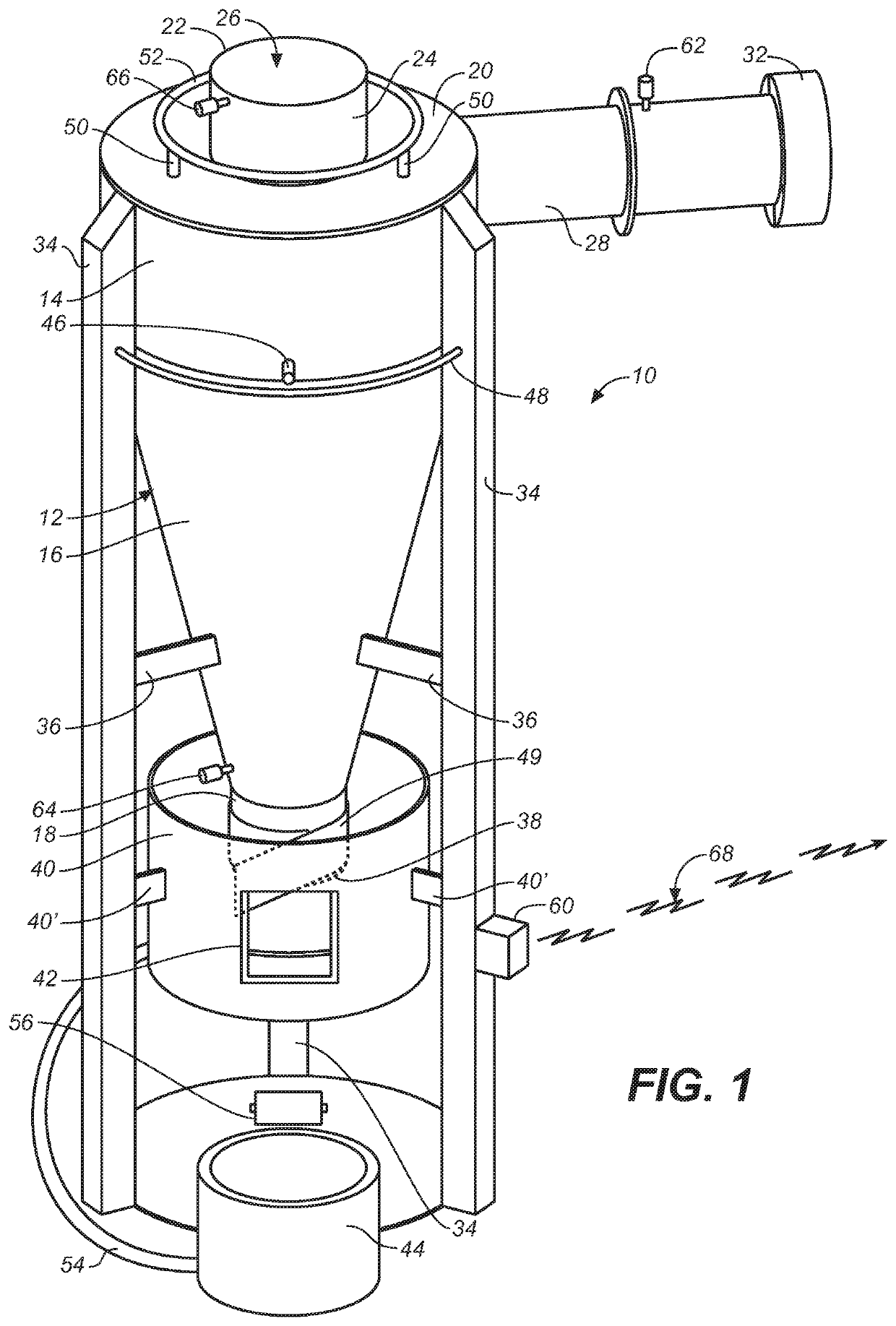

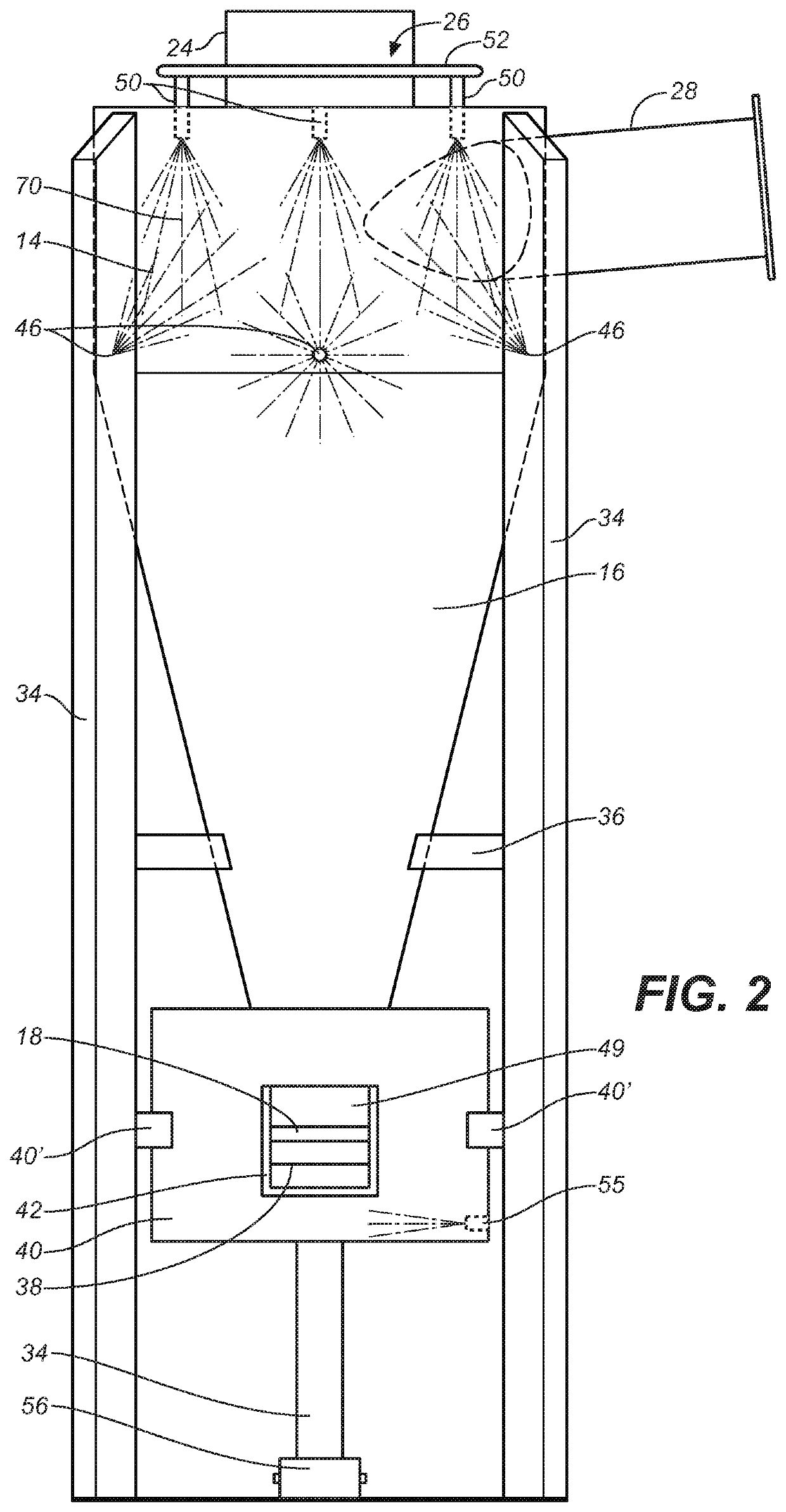

ActiveUS20220032226A1Reduce the risk of injuryIncrease airflowCombination devicesReversed direction vortexParticulatesInterior space

A cyclonic chiller-separator, including a vertically oriented treatment tower defining an interior space and having an exhaust inlet disposed in an upper portion, and a chimney with an exhaust outlet; an exhaust stream conduit in fluid communication with said interior volume of said treatment tower through said exhaust inlet, wherein said exhaust inlet is configured to induce cyclonic fluid motion in an exhaust stream entering said interior volume; a coolant water source; and a plurality of nozzles disposed about interior walls of said treatment tower and in fluid communication with said coolant water source for spraying cooling water into said interior volume above and into an exhaust stream introduced into said interior volume so as to cool, condense, and precipitate volatile organic compounds and organic acids, and to entrain and remove particulates from the exhaust stream.

Owner:VORTX KLEANAIR SYSTEMS

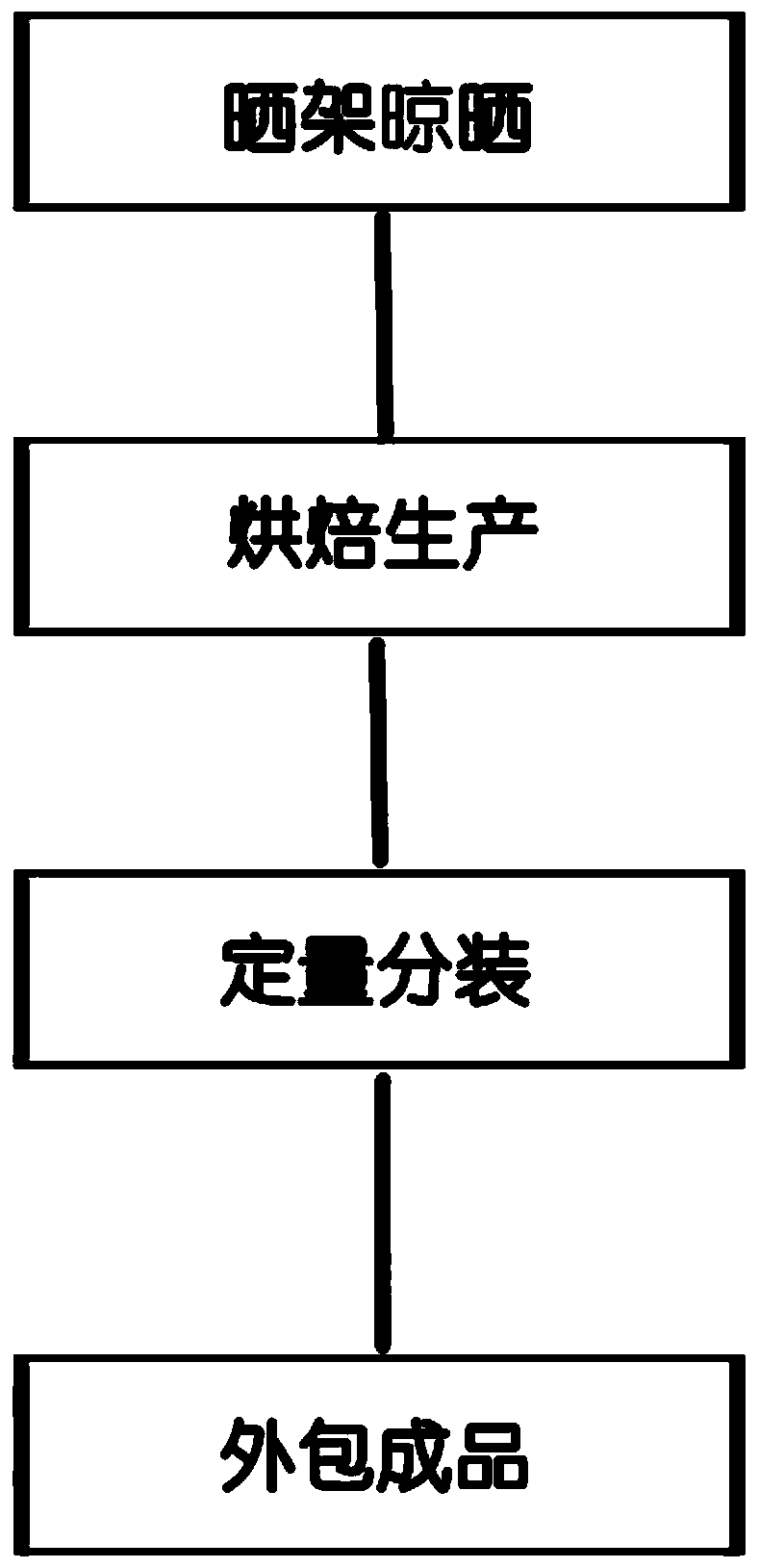

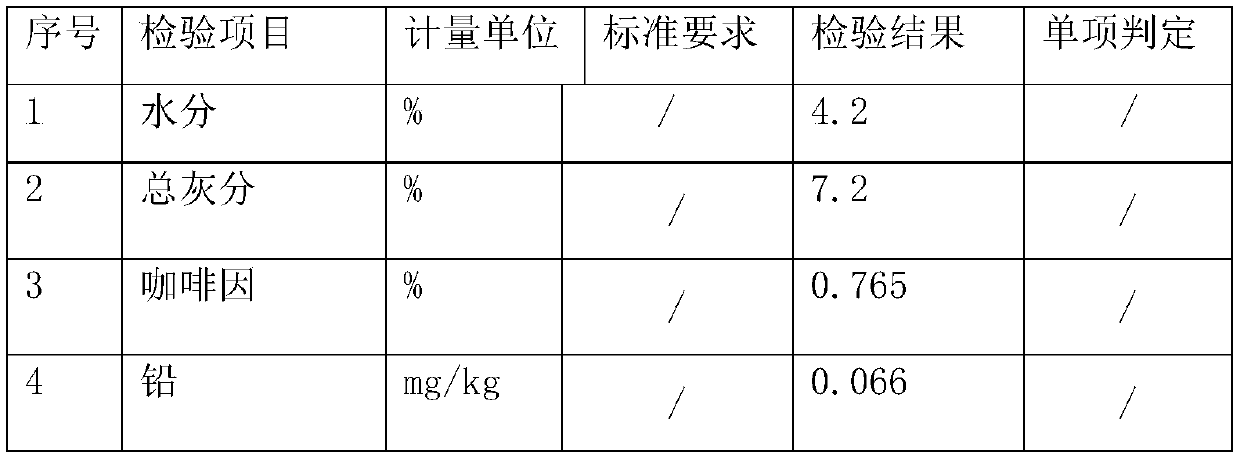

Coffee fruit skin tea and preparation method thereof

InactiveCN109965058AClean and refreshing tasteNo impurityTea substituesRoasted coffee treatmentCooking & bakingMoisture

The invention discloses a preparation method of coffee fruit skin tea. The preparation method comprises the following steps: step A, placing freshly picked coffee fruits on a drying rack to be naturally aired by sunlight irradiation, and airing according to the overturning frequency of fine sun-dried coffee, wherein the airing days are 40-60 days until the moisture of the coffee fruits is aired tobe about 15%; and removing the coffee fruits from the rack and carrying out peeling treatment to obtain coffee bean skins mixed with impurities; step B, removing flaws, coffee beans and fruit skin fragments in the coffee bean skin and coffee fruit skin which are mixed with the impurities in the step A to obtain coffee bean skins for baking; and step C, placing the coffee bean skins for baking inthe step B into a coffee baking machine for baking, controlling the fire power and the heating rate under the condition that the professional temperature of the coffee baking machine is small fire, and obtaining the baked coffee bean skins. The invention also discloses coffee fruit peel tea. The coffee fruit peel tea is fragrant and sweet in taste, clean and refreshing, free of impurity feeling, stable in taste and free of mold taste.

Owner:杨秋湖

Smokeless coffee roaster

A coffee bean roasting machine of the type having a cyclone separator heating chamber and a coffee bean roasting chamber in a recirculating process stream driven by a recirculation fan is operated to air cool the roasted coffee beans in the roasting chamber, to a temperature beneath which the beans give off smoke, while at the same time incinerating smoke removed from the roasting chamber. A purge gate in ducting between the cyclone separator and the roasting chamber is opened to allow the flow of ambient air into and through the roasting chamber while blocking flow out of the cyclone separator, so that ambient air is directed through the roasting chamber. The smoke and any airborne particulate material from the roasting chamber are carried into the heating chamber and through the incineration tube, where they are incinerated. Preferably the system and process are operated automatically by a computer and programming.

Owner:LORING SMART ROAST

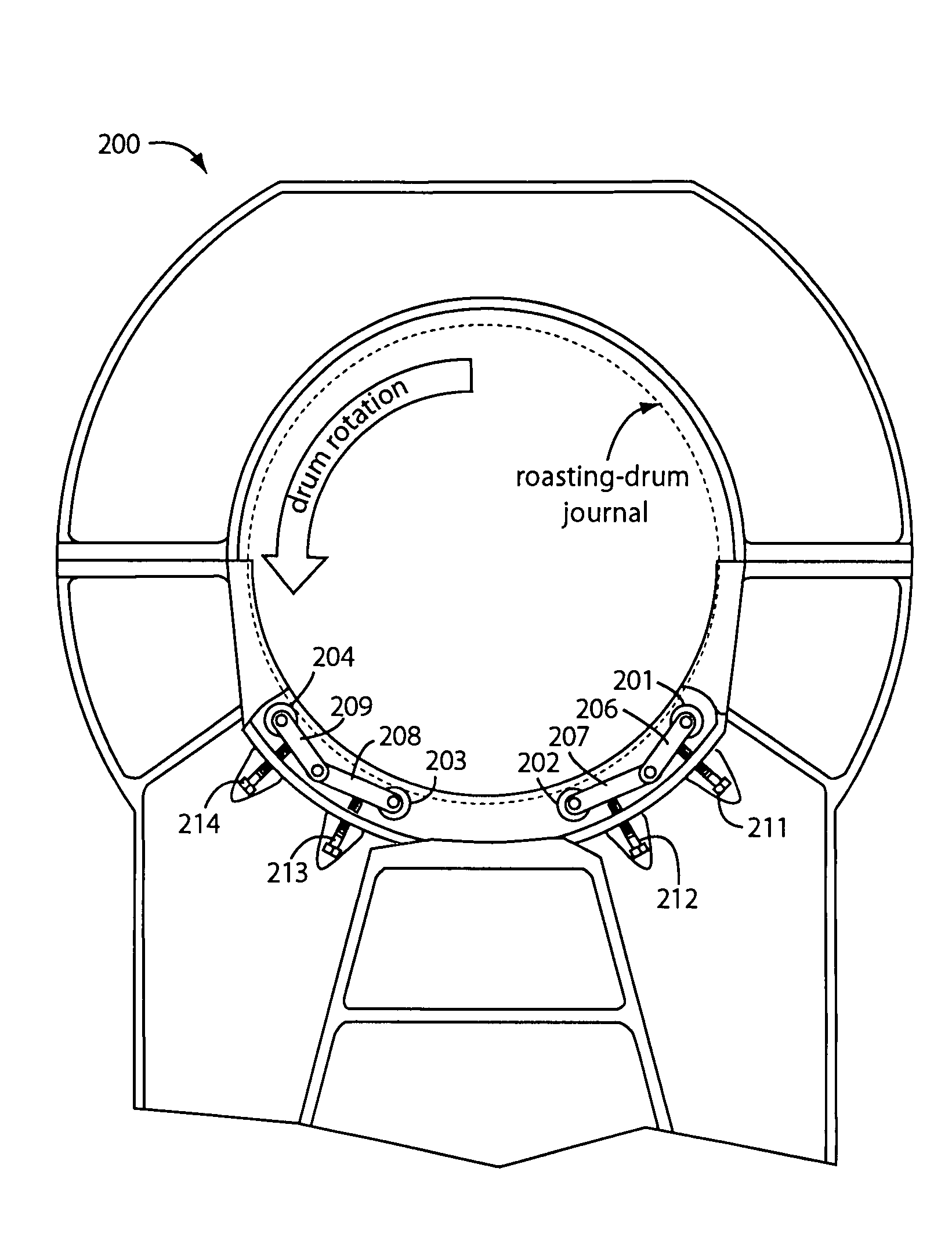

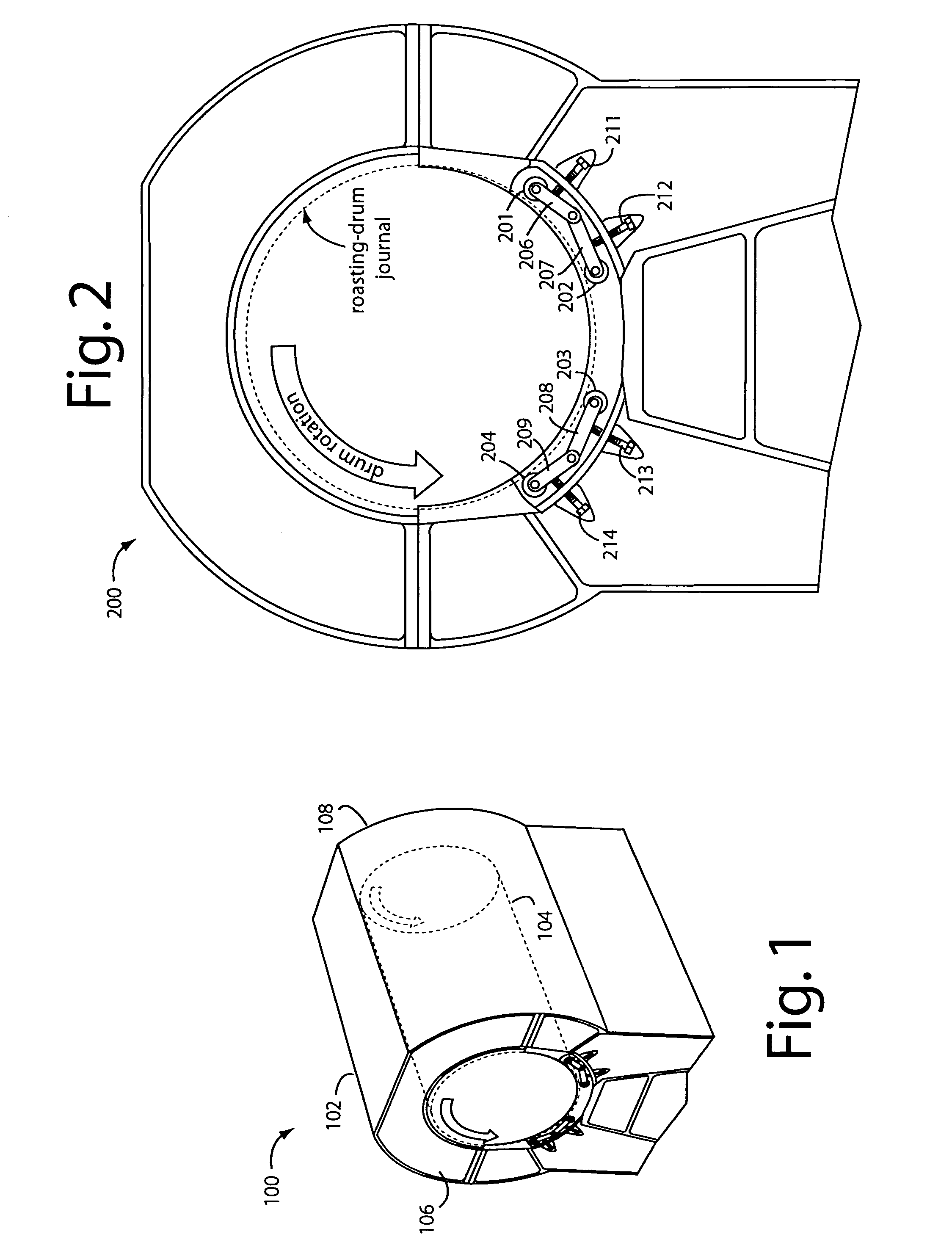

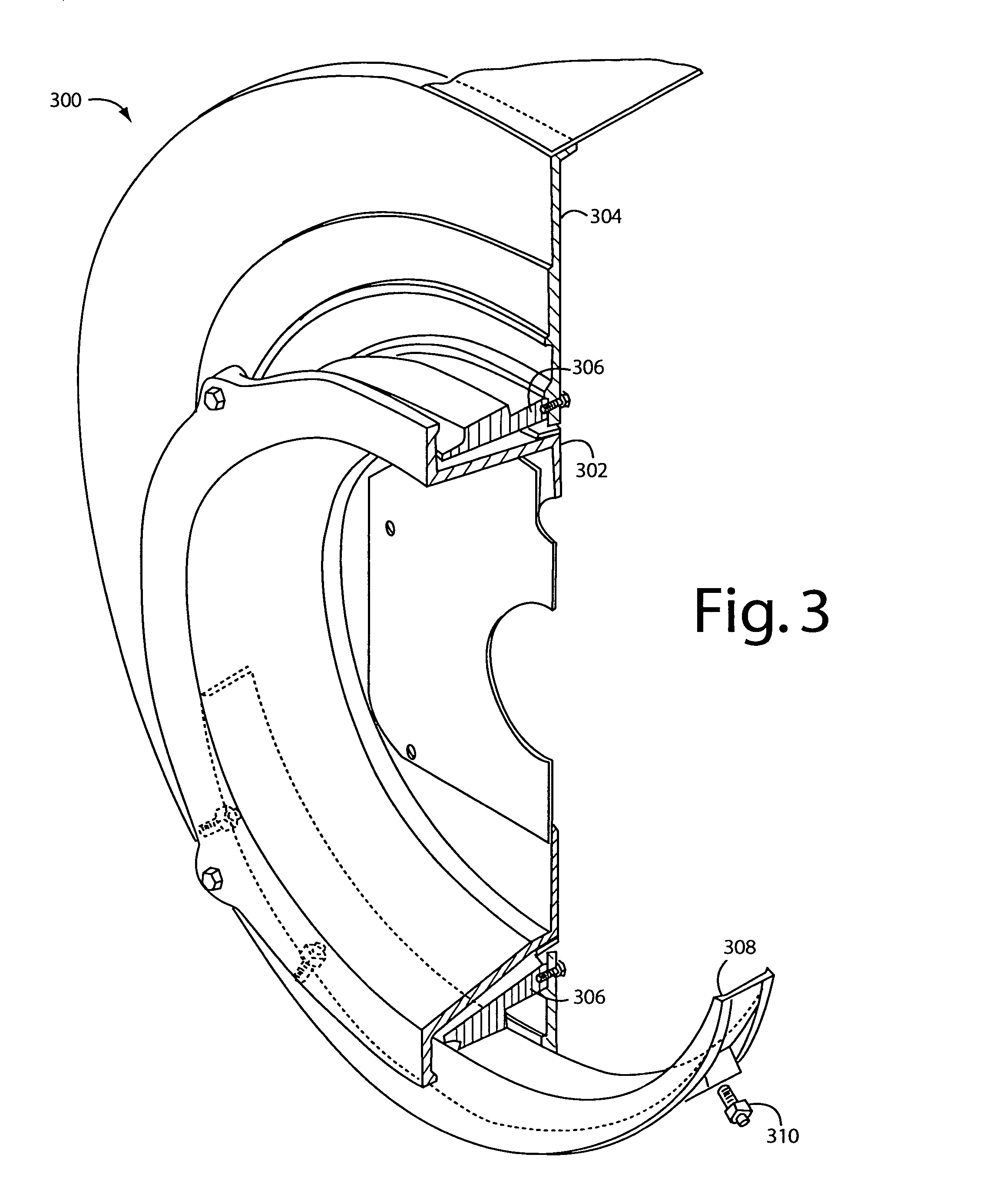

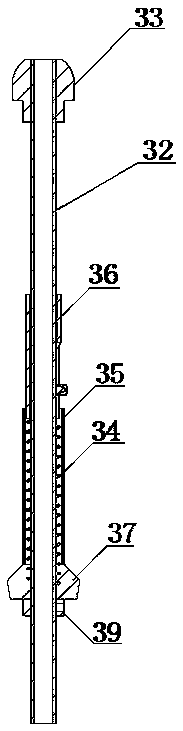

Coffee roaster drum rocker arm roller bearing system

InactiveUS7003897B1Extended service lifeDrying solid materials with heatDrying machines with non-progressive movementsHorizontal axisEngineering

A coffee roaster is an oven with a roasting drum. The roasting drum turns on a horizontal axis within the oven to tumble coffee beans while roasting and to even out differences in heating. The roasting drum is fitted with a bearing journal at each end and just fits within the length of the oven. Opposite ends of the oven have four rollers each that receive the turning weight of the roasting drum by riding along the bearing journals. Each roller wheel is carried at the distal end of a rocker arm attached by its near end to the lower end wall of the oven below a corresponding drum opening. Each in a set of four roller wheels are height adjustable at the 4-o'clock, 5-o'clock, 7-o'clock, and 8-o'clock positions. The two outer rockers and wheel rollers adjust the lateral position of the roasting drum in the oven, and the two inner ones adjust the vertical height of rotation within the oven.

Owner:LINGLE JAMES B +1

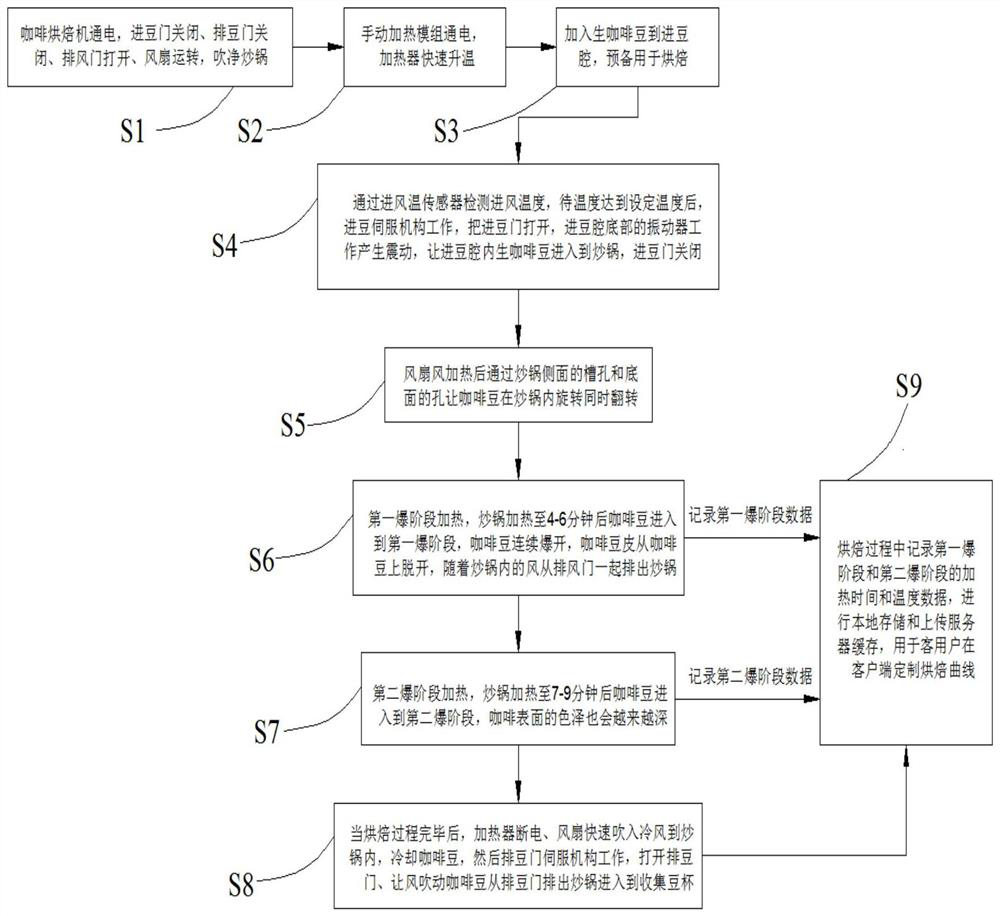

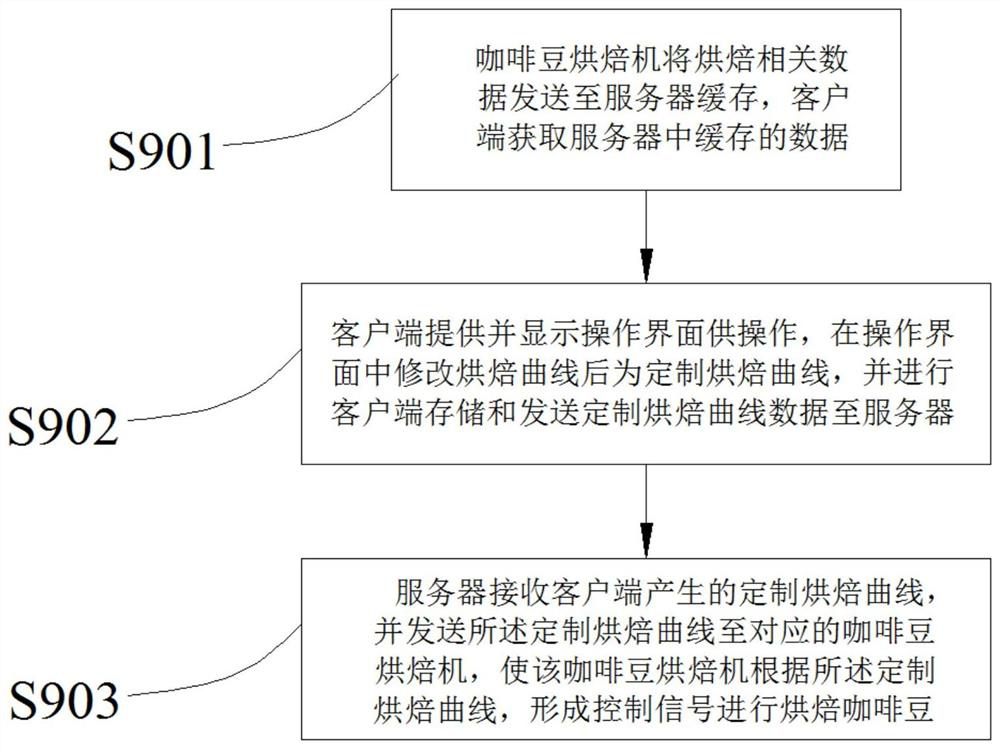

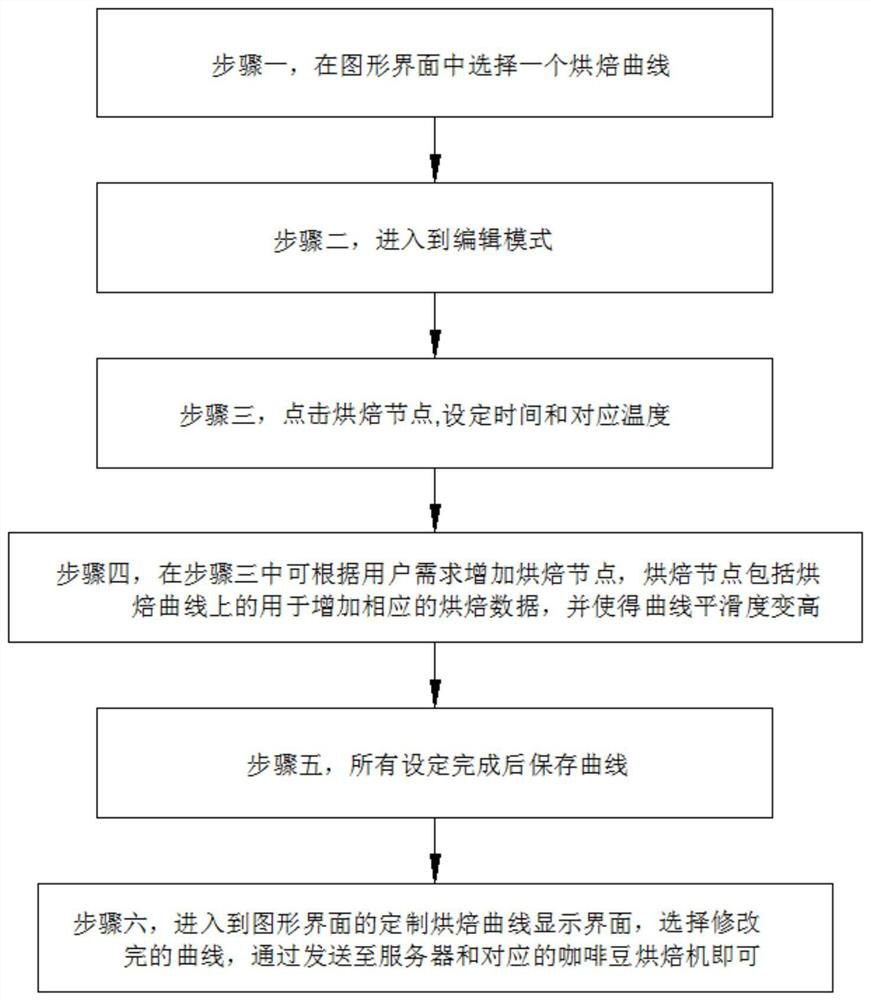

Coffee bean refined baking method, system and equipment

ActiveCN114631636AMeet your own needsIncrease stickinessTransmissionFood treatmentControl systemProcess engineering

The invention discloses a coffee bean refined baking method, system and equipment, and the method comprises the following steps: checking, cleaning and preheating before treatment, heating coffee beans in a first explosion stage, heating coffee beans in a second explosion stage, discharging coffee beans and discharging residues, and recording the heating time and temperature data of the first explosion stage and the second explosion stage in the baking process; according to the method and the system, data of the client side and the coffee baking machine are stored locally and uploaded to the server for caching, so that a user can customize a baking curve at the client side, the client side modifies the baking curve in an operation interface to form a customized baking curve, and the coffee baking machine can be controlled. The client side can correspondingly modify the baking curve according to requirements, so that the baking process is more refined and diversified, self-set requirements of different users are met, the coffee baking machine and a control system are improved, and intelligent, informationized, stable and precise operation of the coffee baking machine is improved.

Owner:南京艾文捷电子科技有限公司

Coffee roaster having an apparatus for increasing airflow in a roasting chamber

InactiveUS7360481B2Increase air velocityDomestic stoves or rangesElectrical heating fuelCoffee roasterWaste management

A roaster for roasting coffee beans includes a roasting chamber having a top and a bottom. A cover is seated on the top of the roasting chamber and a bottom of the roasting chamber is seated on a base. A hot air supply is provided in the base for supplying hot airflow into the roasting chamber for heating the coffee beans. At least one air opening is formed on the bottom for enabling the airflow to enter the roasting chamber. A wind tunnel is provided over the air opening for increasing the speed of the airflow in the roasting chamber as the airflow passes through the wind tunnel.

Owner:NUWAVE

Temperature controlled exhaust stream water filter for coffee roasters

ActiveCN113438982AOdor suppressionVisible smoke reductionCombination devicesReversed direction vortexParticulatesWater filter

A cyclonic chiller-separator, including a vertically oriented treatment tower defining an interior space and having an exhaust inlet disposed in an upper portion, and a chimney with an exhaust outlet; an exhaust stream conduit in fluid communication with said interior volume of said treatment tower through said exhaust inlet, wherein said exhaust inlet is configured to induce cyclonic fluid motion in an exhaust stream entering said interior volume; a coolant water source; and a plurality of nozzles disposed about interior walls of said treatment tower and in fluid communication with said coolant water source for spraying cooling water into said interior volume above and into an exhaust stream introduced into said interior volume so as to cool, condense, and precipitate volatile organic compounds and organic acids, and to entrain and remove particulates from the exhaust stream.

Owner:VORTX KLEANAIR SYSTEMS

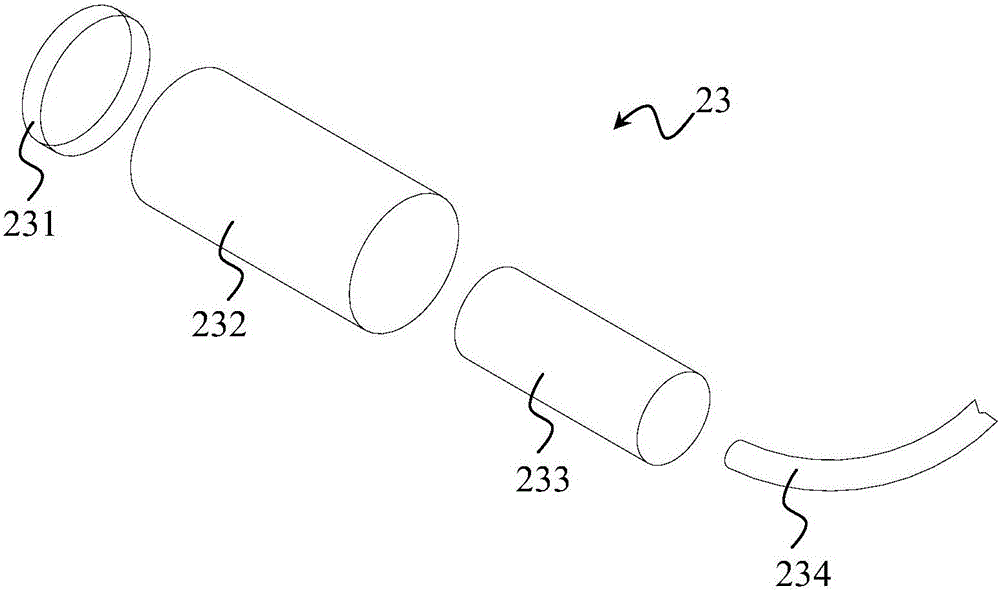

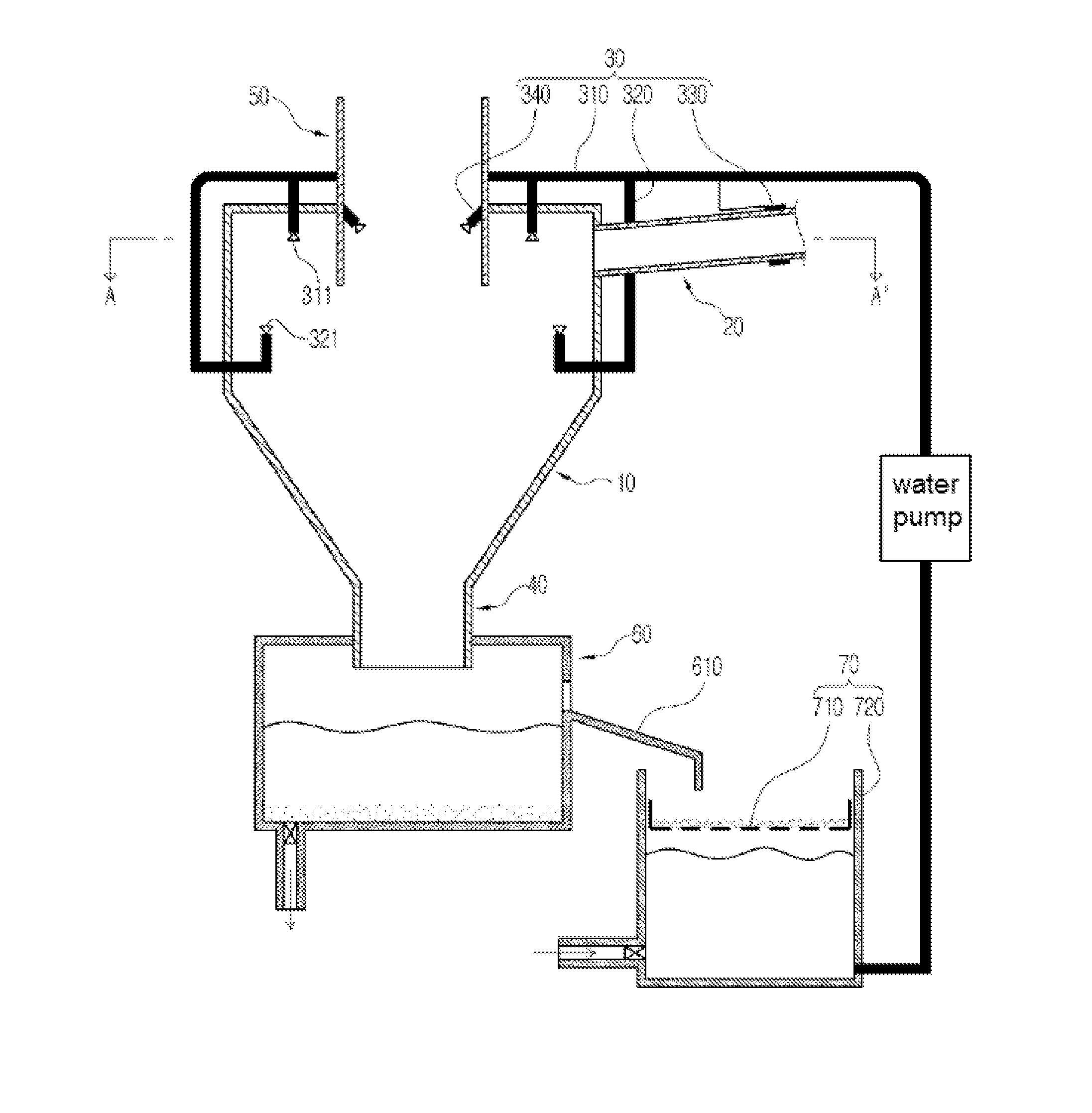

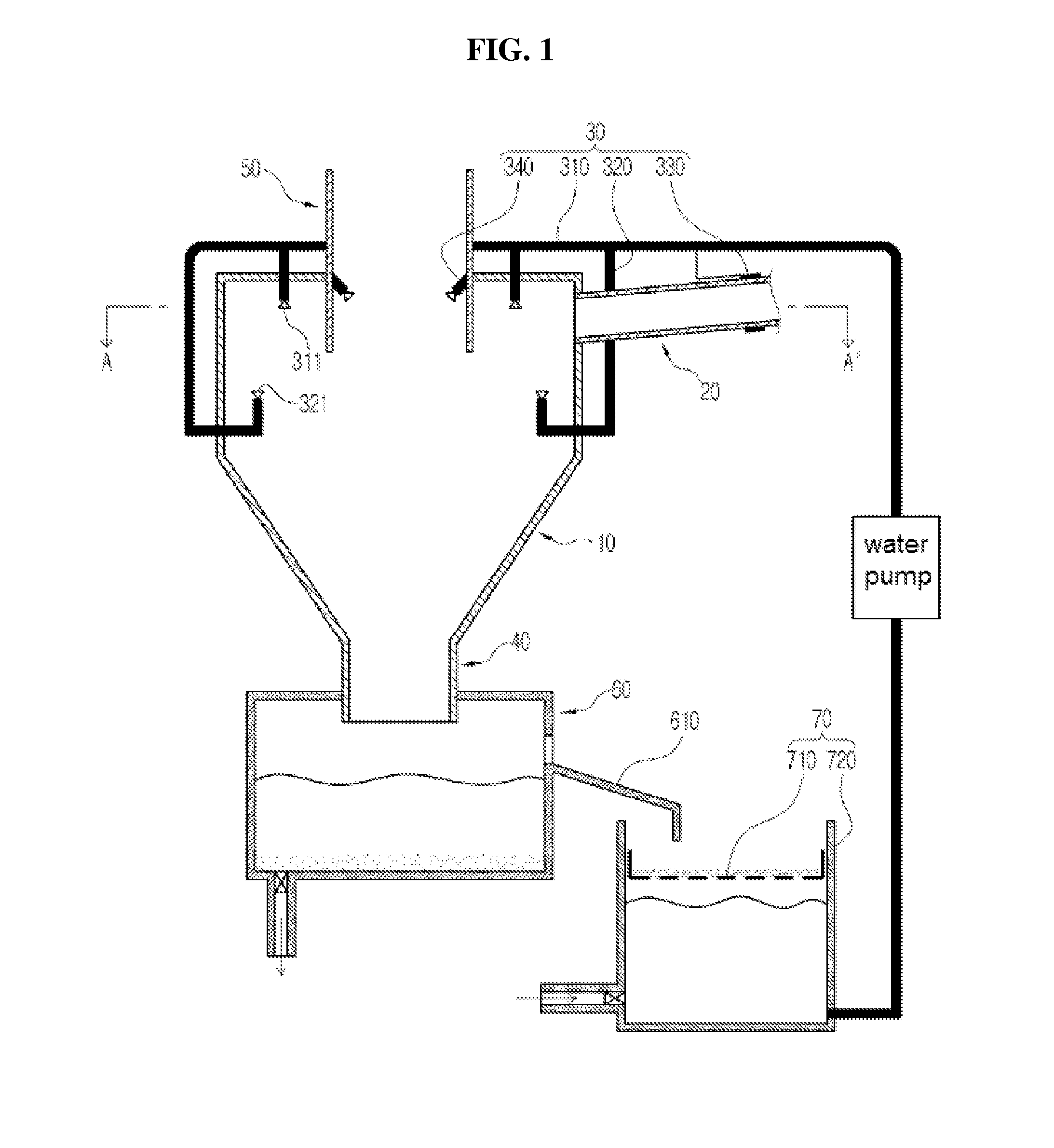

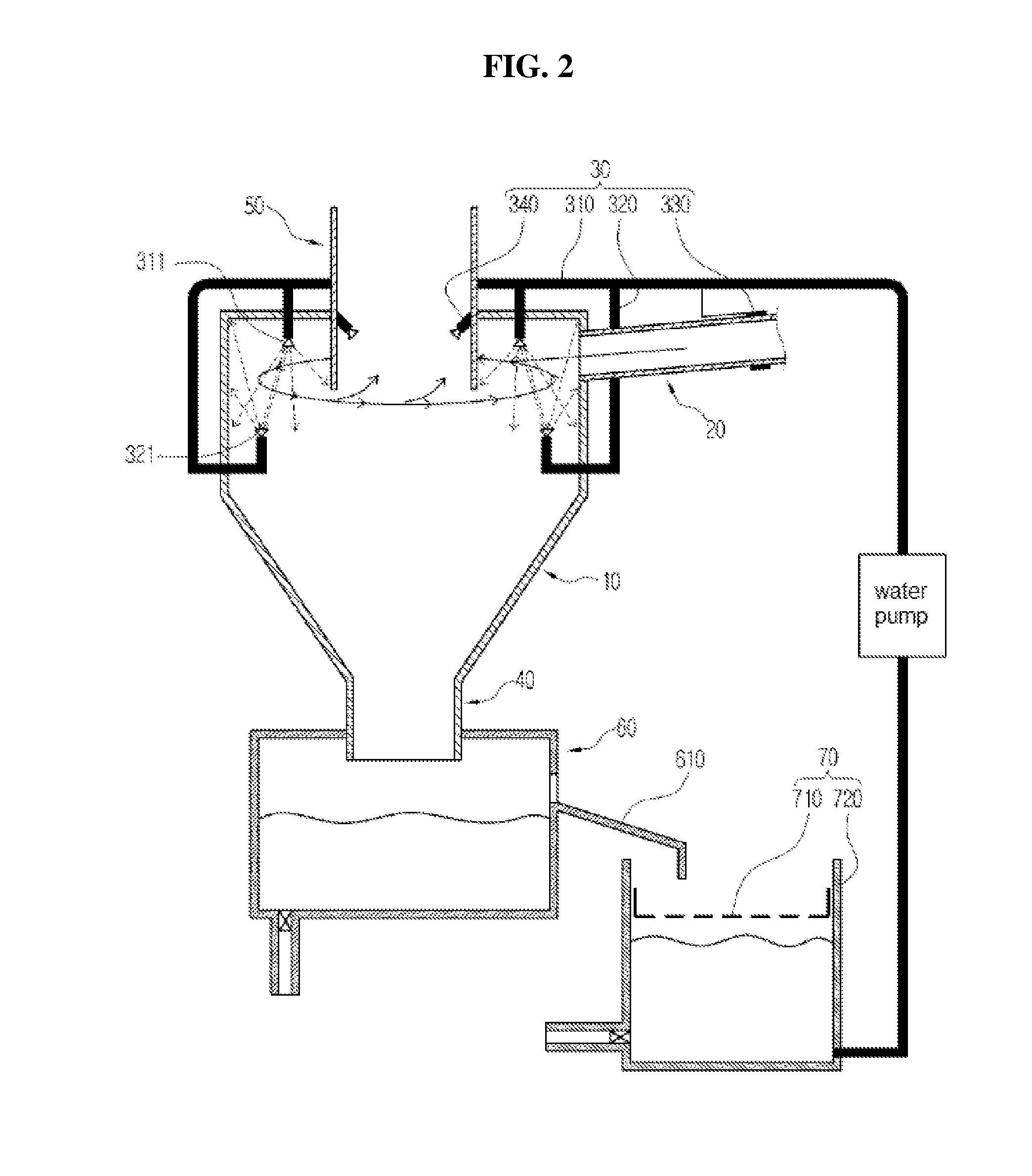

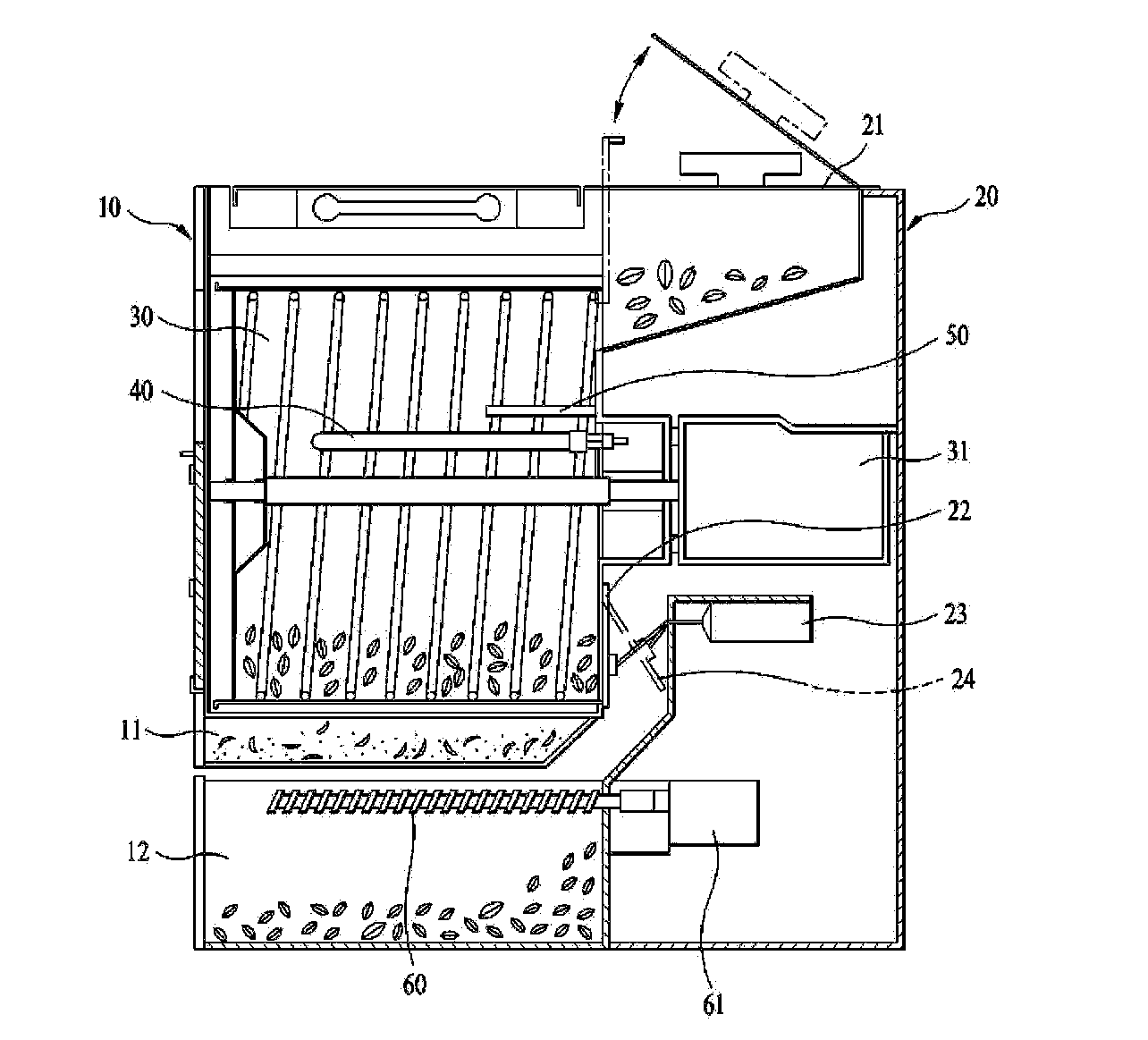

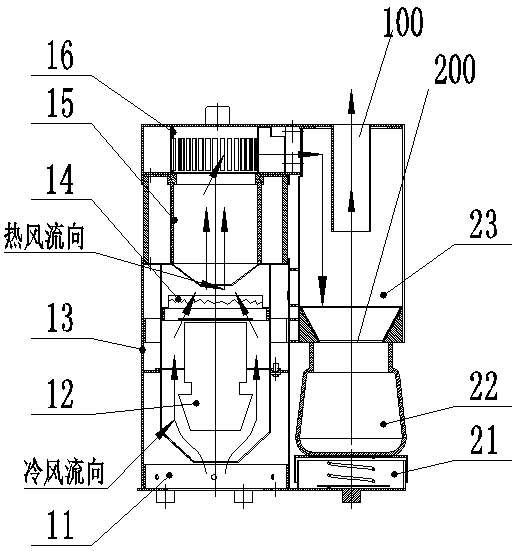

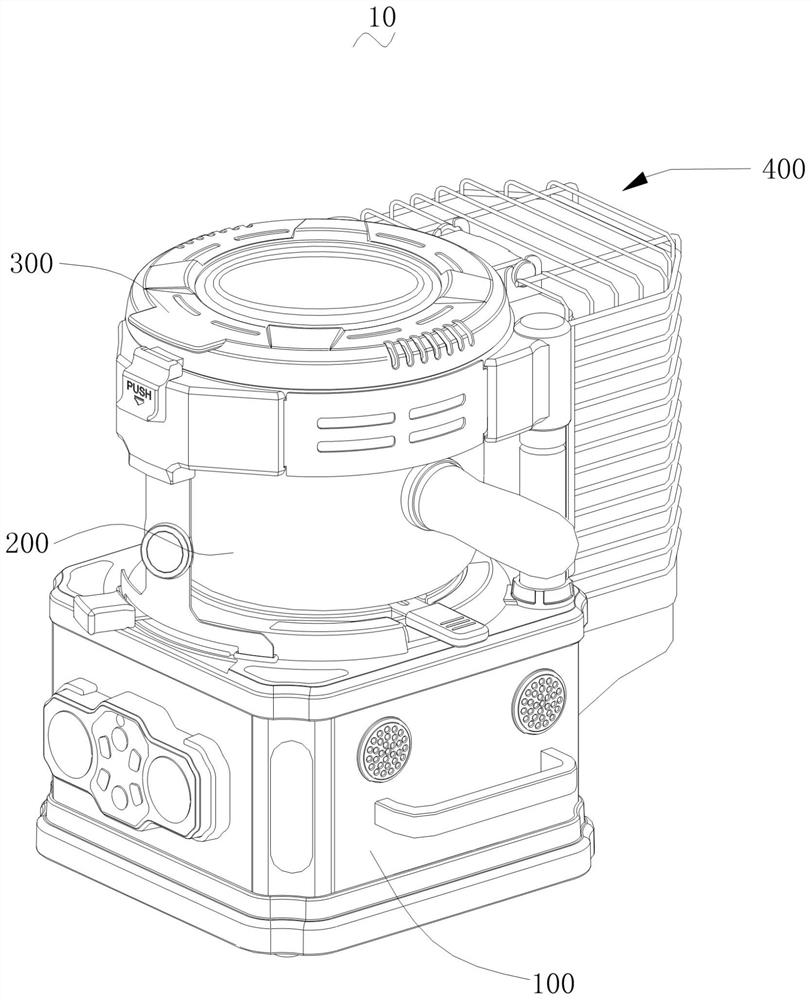

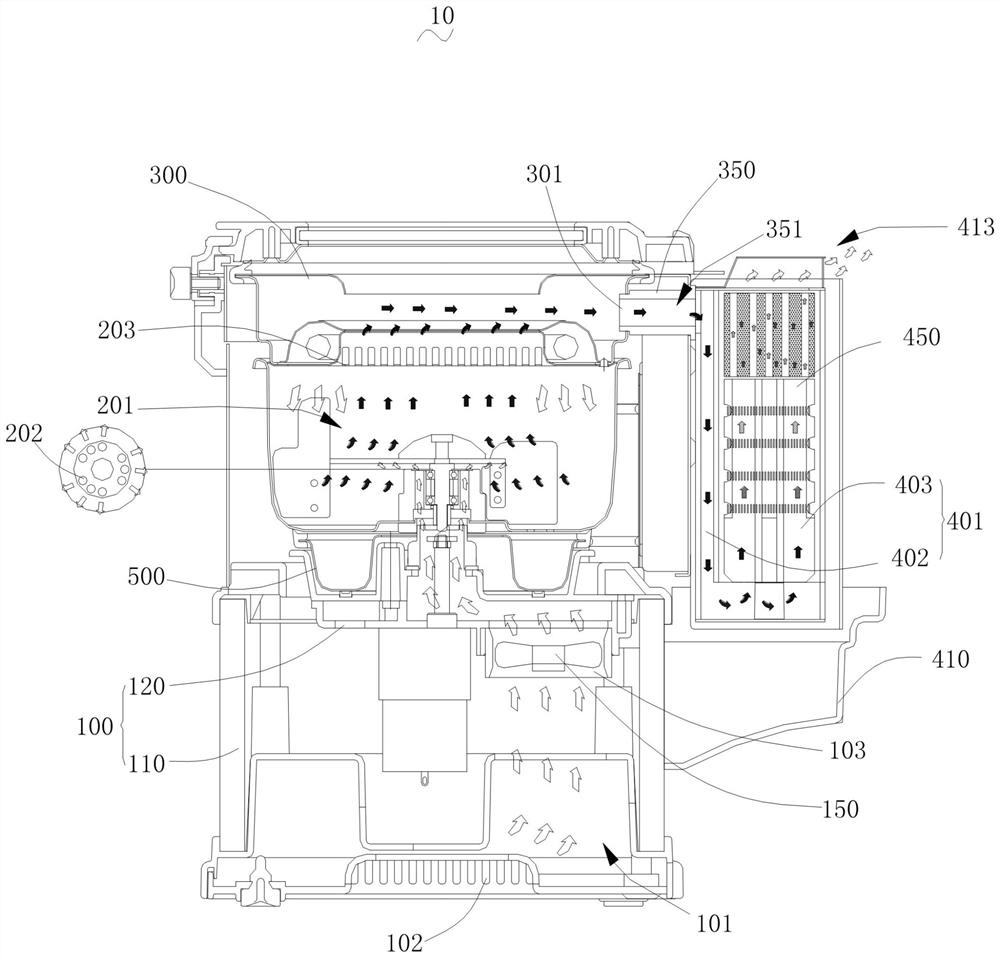

Hot air type automatic coffee baking machine and control system thereof

PendingCN111588054ABaking is simple and easy to understandBreakthrough in Baking QualityCo-operative working arrangementsTransmissionThermodynamicsControl system

The invention provides a hot air type automatic coffee baking machine and a control system thereof. The hot air type automatic coffee baking machine comprises a frying barrel assembly, a smoke exhauststorage assembly and an electric control assembly, wherein the frying barrel assembly comprises a baking heat source and a baking chamber; the baking chamber is provided with a transparent observation wall for observing coffee bean baking; the baking heat source comprises a fan and a heating wire which are controlled by the electric control assembly, and raw materials in the baking chamber are baked by output hot air; a control system is embedded in the electric control assembly, the working modes of the electric control assembly comprise manual baking and automatic baking, and the control system records the working conditions of the baking heat source at all stages of the coffee bean baking process and stores the working conditions as a baking scheme corresponding to the baking quality;and when the working mode of the electric control assembly is automatic baking, the control system controls the fan and the heating wire according to the working conditions of the baking heat source recorded in the baking scheme. The hot air type automatic coffee baking machine has a silver skin separation function, and the better coffee bean baking process can be stored as the automatic baking scheme which can be called repeatedly.

Owner:FUJIAN AGRI & FORESTRY UNIV +1

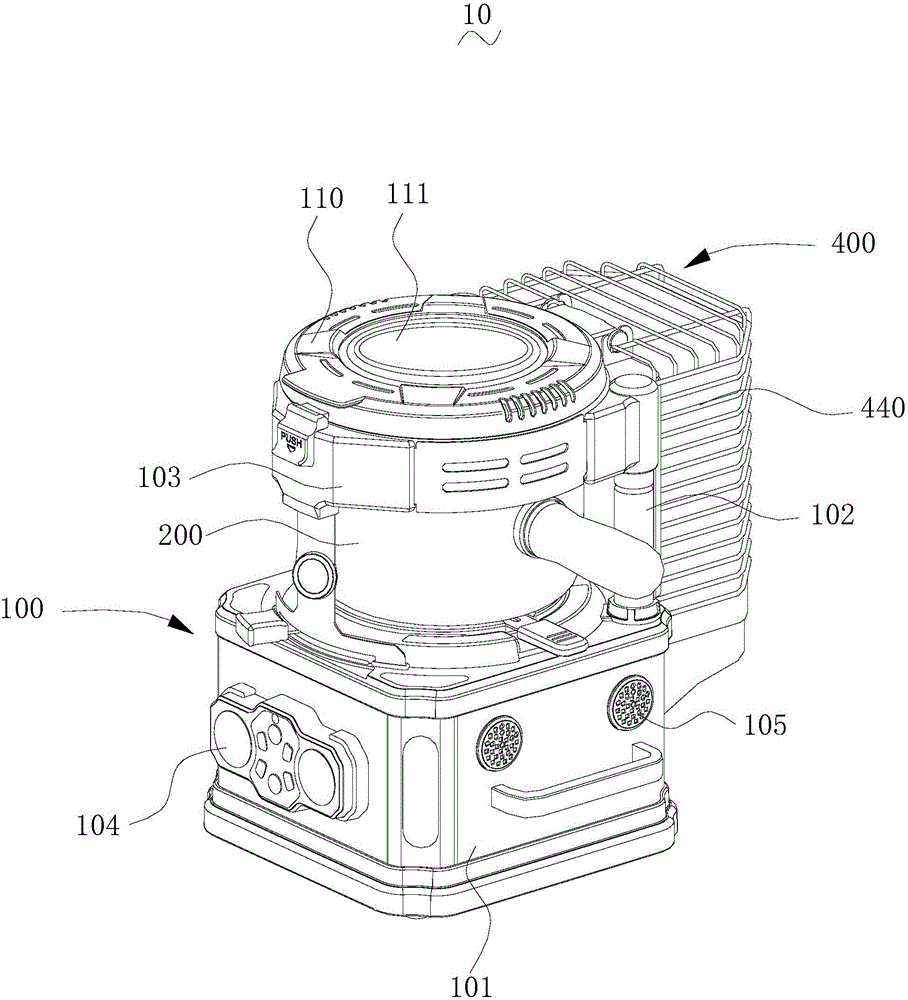

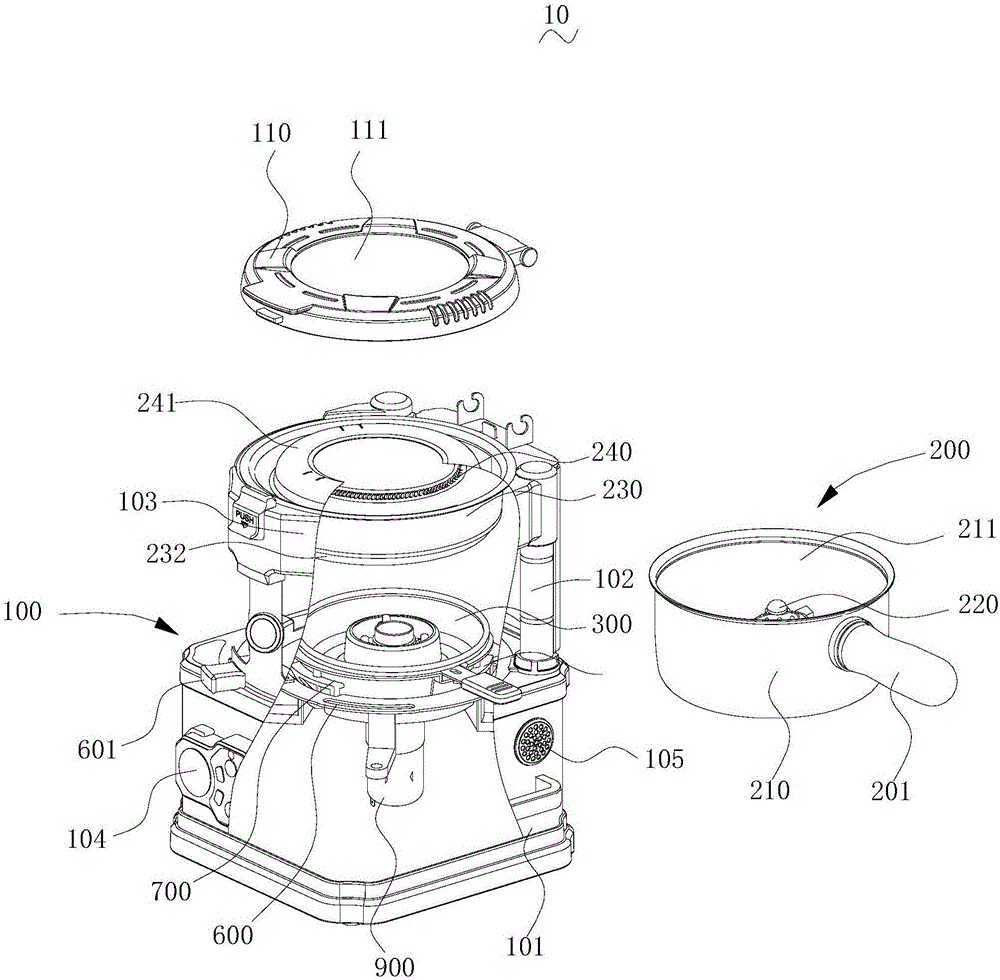

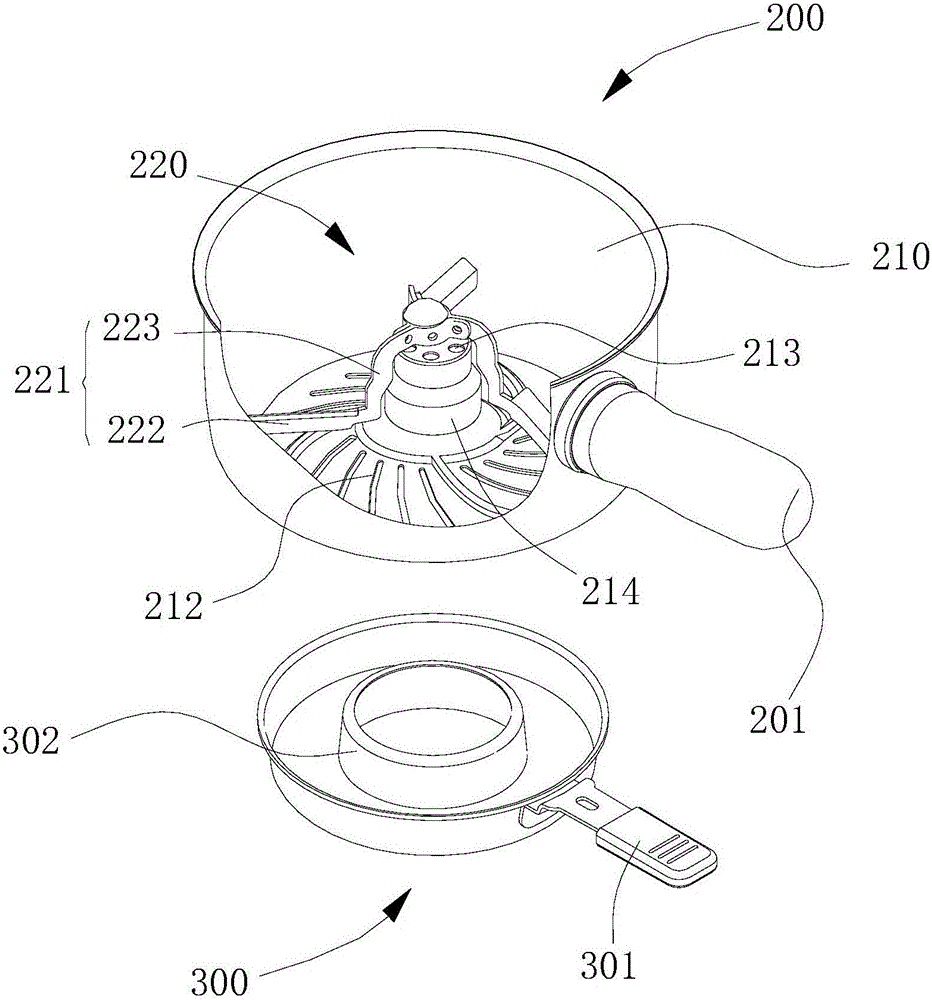

Coffee baking machine

InactiveCN112450466ADischarge in timeImprove the baking effectFood treatmentMechanical engineeringCoffee roaster

The invention relates to a coffee baking machine. The coffee baking machine comprises a base, a baking container, a top cover and a smoke exhaust device, the baking container is arranged on the base,a baking cavity is formed in the baking container, a cavity opening is formed in the top of the baking container, an air blowing hole is formed in the bottom of the baking container, the air blowing hole and the cavity opening communicate with the baking cavity, the top cover seals the cavity opening, an air inlet channel and an air outlet channel are formed in a coffee baking machine body, the air inlet channel comprises multiple air inlet holes formed in the bottom of the base, a cavity formed in the base and an air supply duct, the air inlet holes communicate with the cavity, the air outletchannel comprises a connecting port formed in the top cover and a smoke exhaust channel formed in the smoke exhaust device, and the baking cavity communicates with the smoke exhaust channel through the connecting port. According to the coffee baking machine, the air inlet channel communicates with the bottom of the baking cavity, the air outlet channel communicates with the top of the baking cavity, so that air can circulate in the coffee baking machine body from bottom to top, and the baking effect on coffee beans in the baking cavity is better.

Owner:惠州市荣光五金电子有限公司

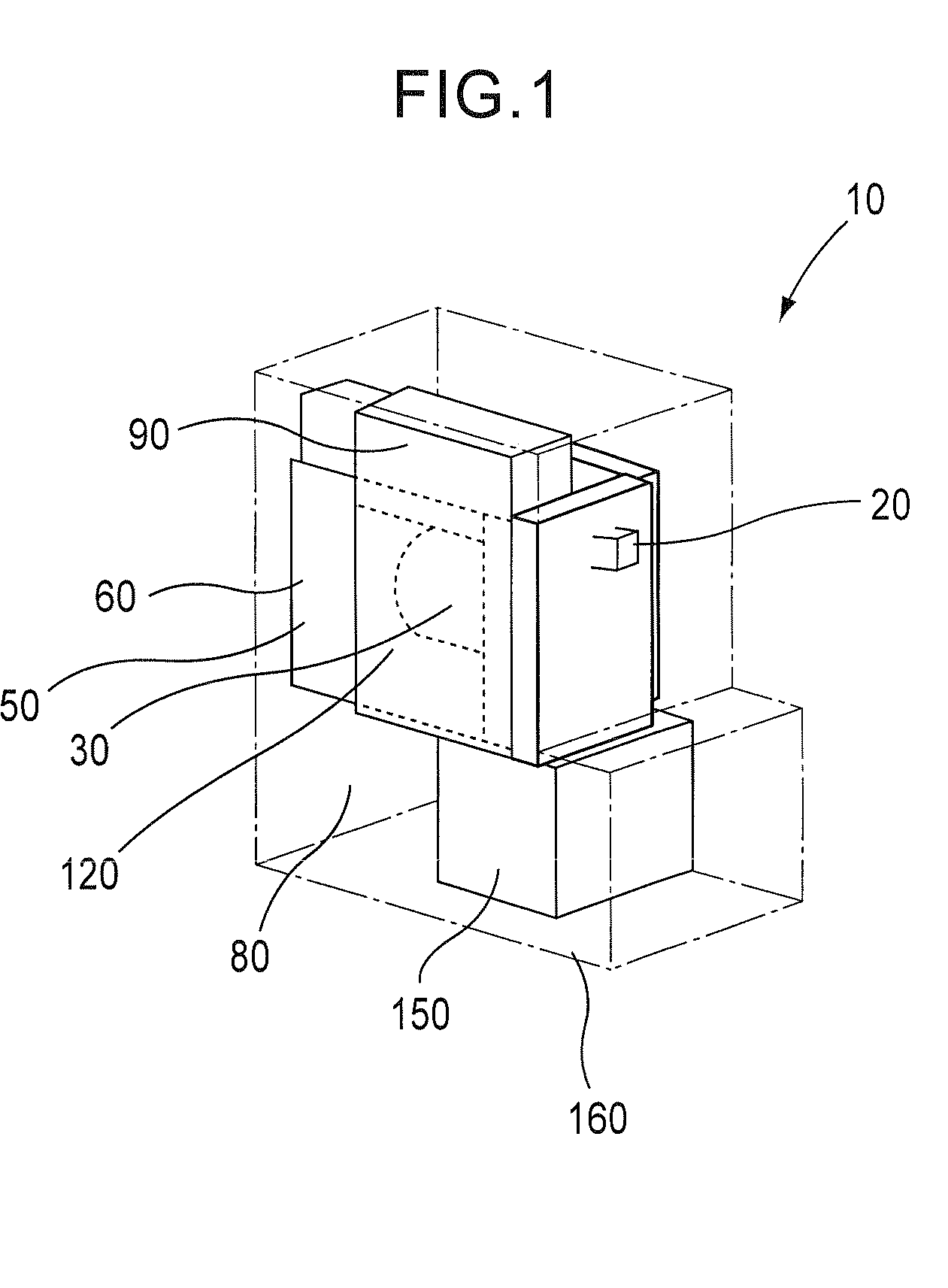

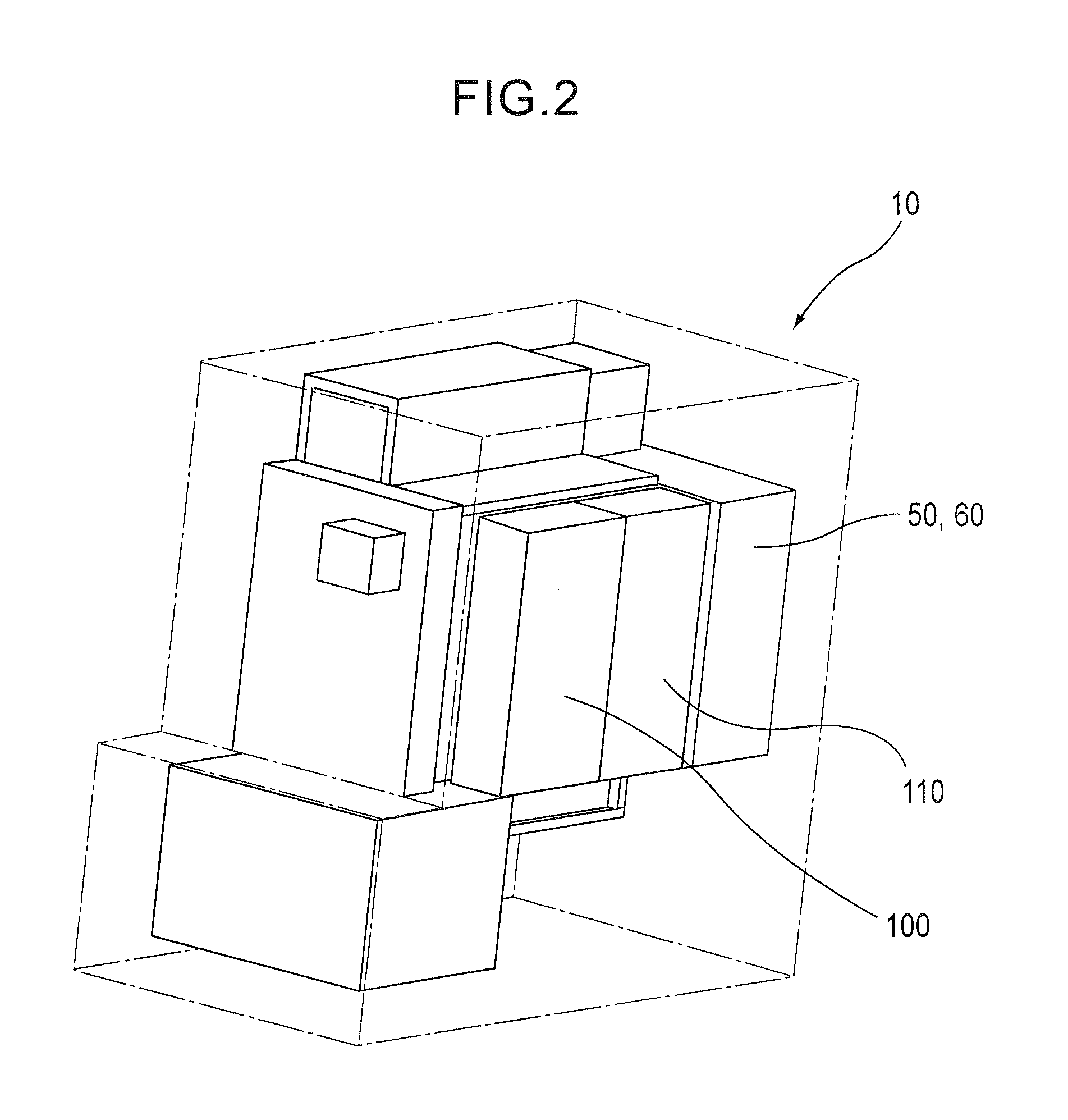

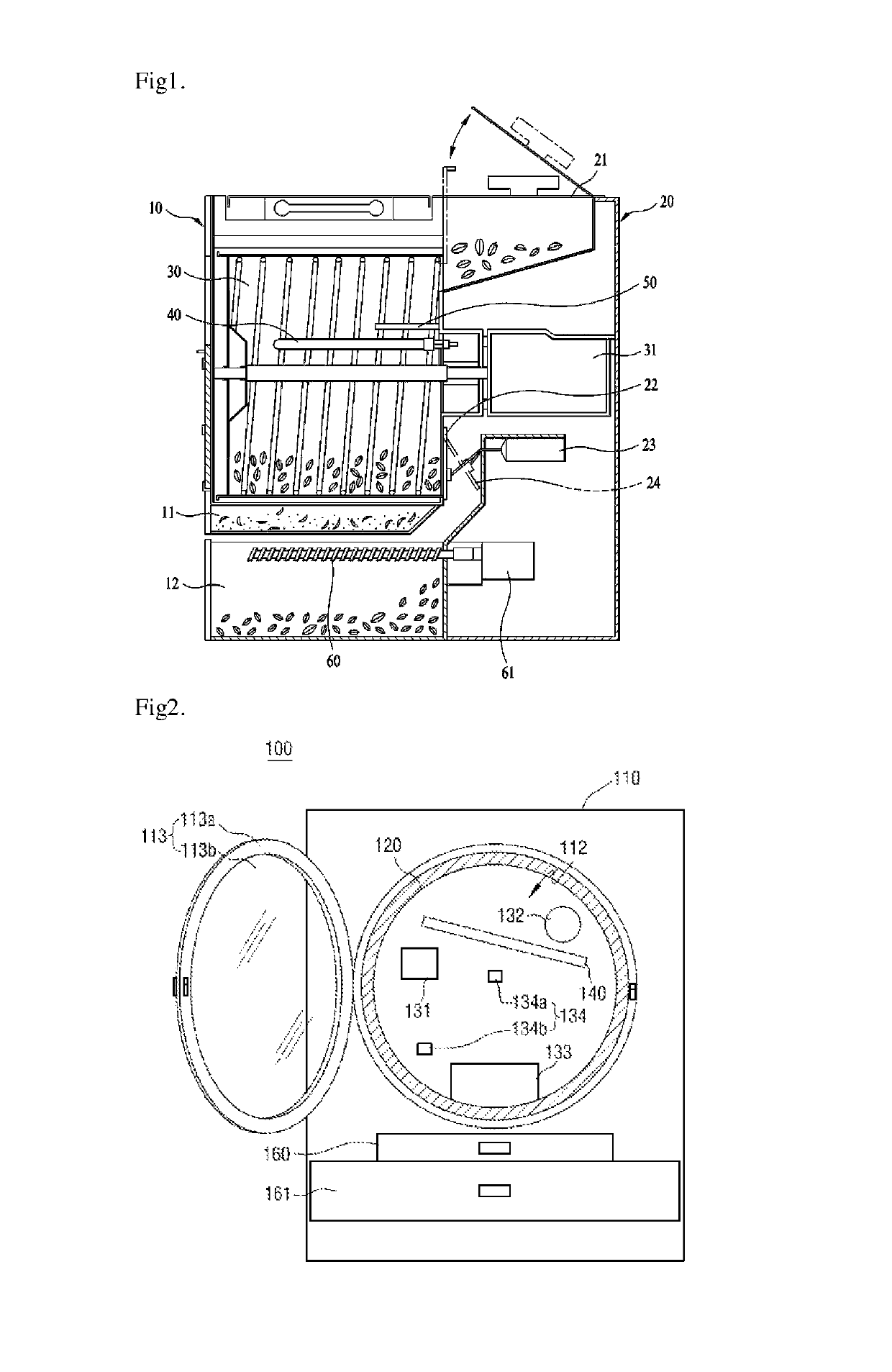

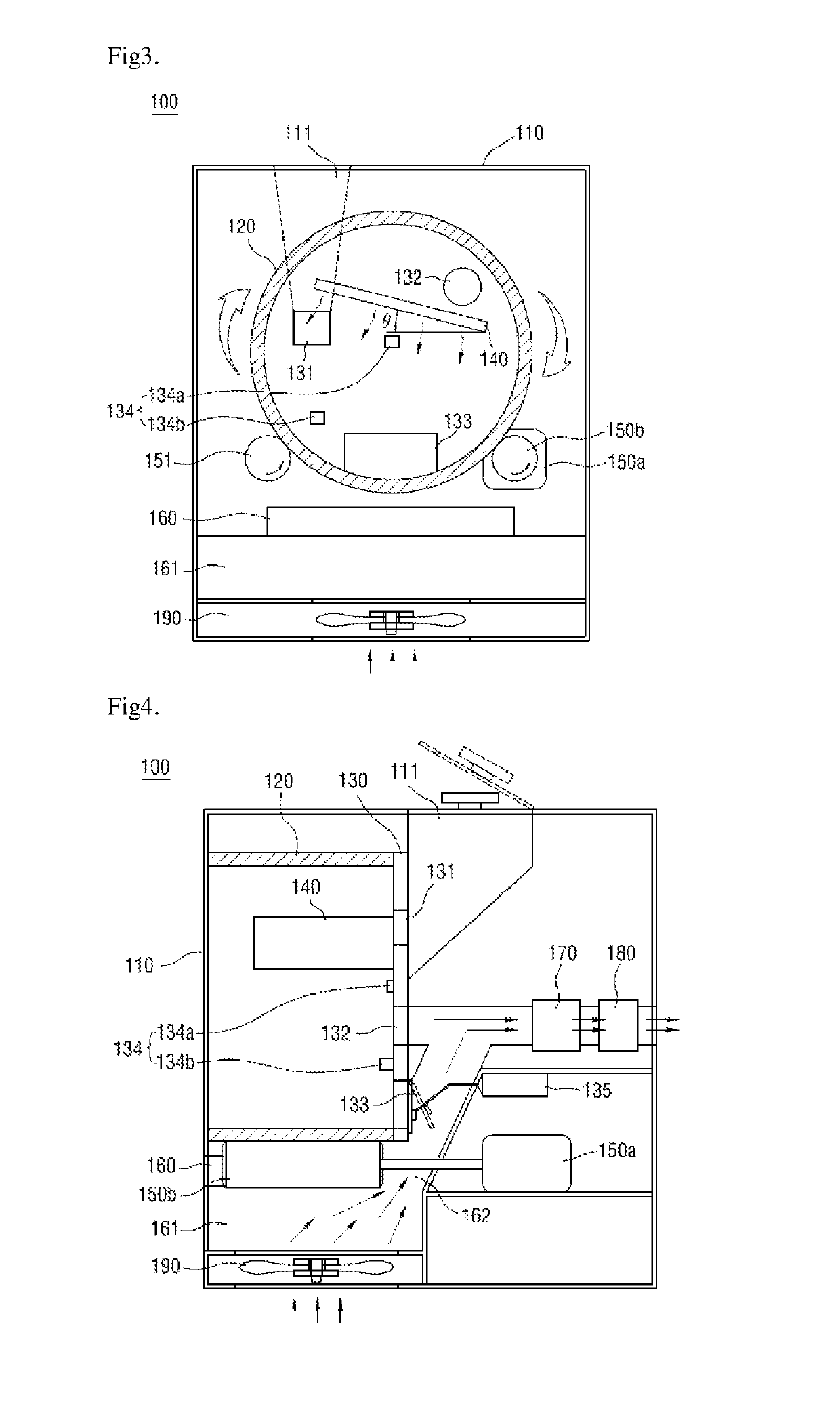

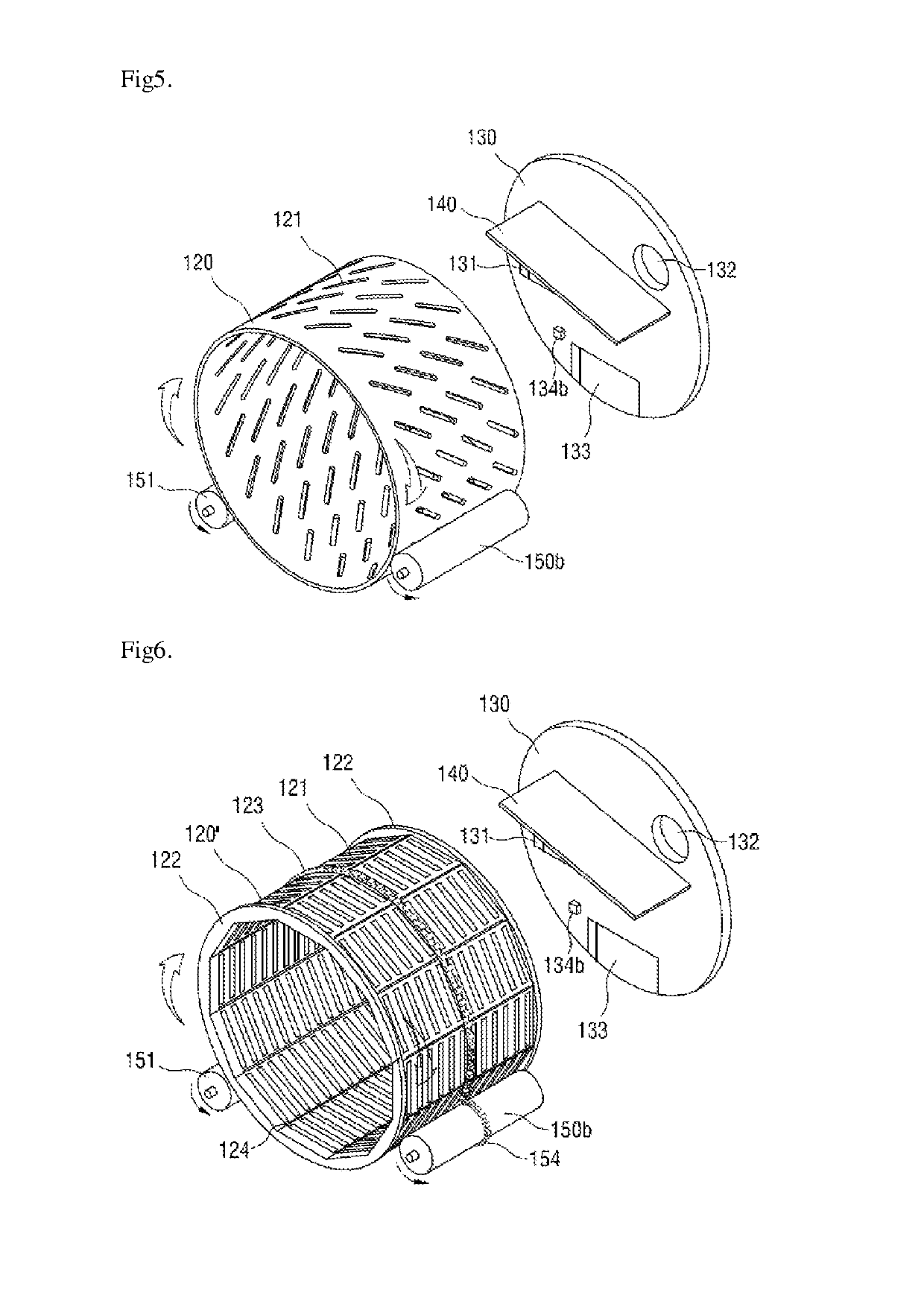

Coffee roaster

ActiveUS10448663B2Easy to control temperatureAccurate operationCoffee roasting methodsFood treatmentEngineeringMechanical engineering

The present invention relates to a coffee roaster having a housing, a supporting plate located within the housing, a drum chamber located at one side of the supporting plate within the housing, a first support for supporting the drum chamber, and a second support for supporting the drum chamber. The supporting plate may include a heater. The first support may be adjacent to the outer circumferential surface of the drum chamber. The second support may be adjacent to the outer circumferential surface of the drum chamber and be spaced apart from the first support by a predetermined distance. As the drum chamber rotates by receiving a driving force for rotation from the first supporting unit, the drum chamber can be rotated without being obstructed by the heater.

Owner:CM TECH CO LTD

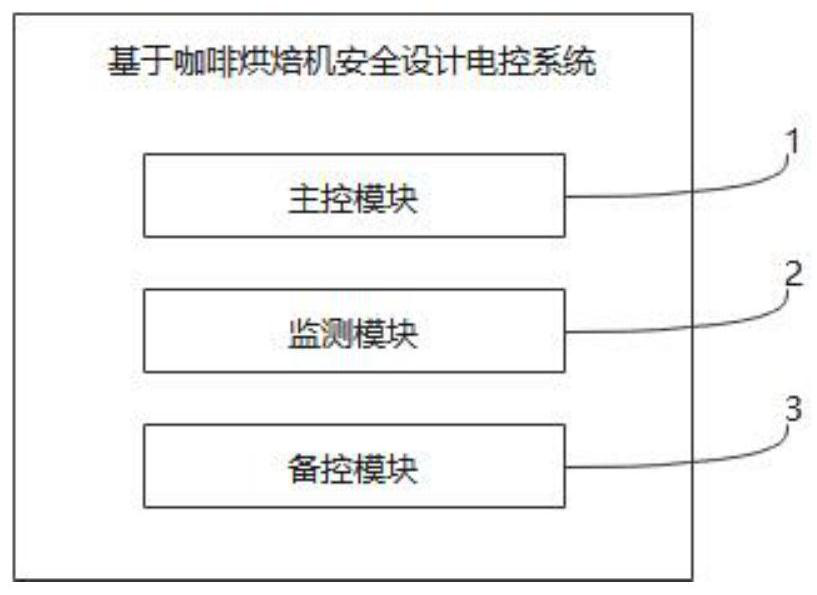

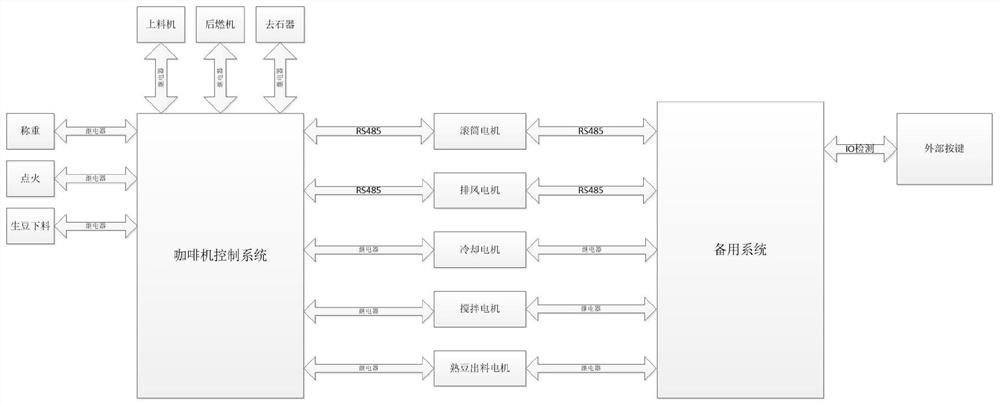

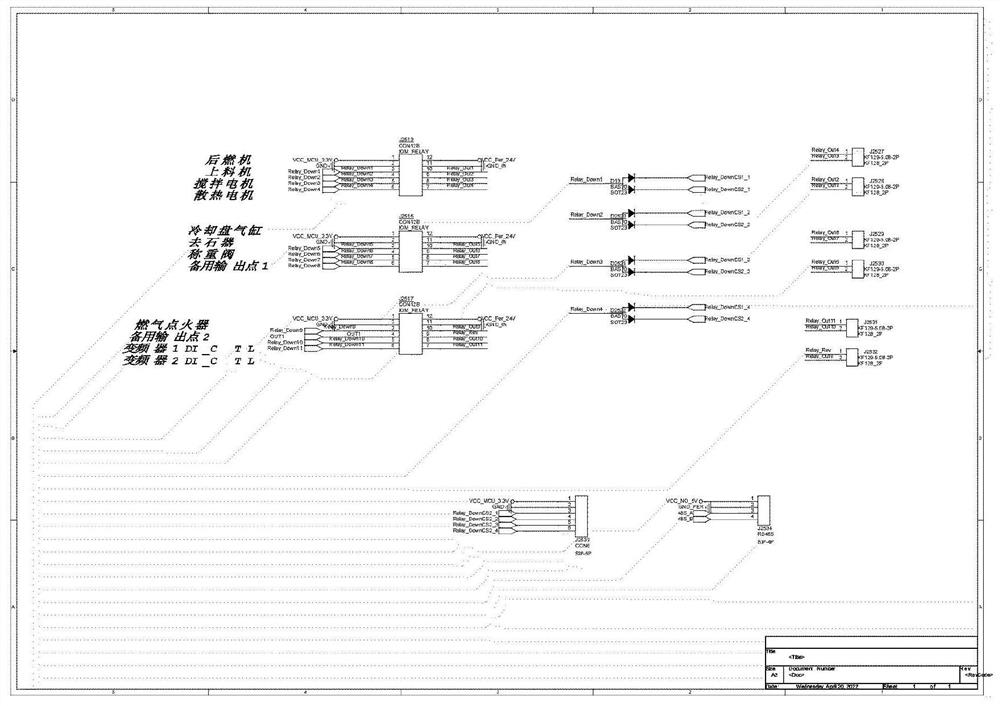

Electric control system based on safety design of coffee baking machine

PendingCN114879563AAvoid damageReduce wasteProgramme controlComputer controlControl engineeringElectric machinery

The invention provides a safety design electric control system based on a coffee roaster, and the system comprises a main control module which is used for controlling all execution mechanisms in the coffee roaster; the monitoring module is used for monitoring the running state of the main control module; and the standby control module is used for taking over the control authority of a part of execution mechanisms in the coffee baking machine when the operation state of the main control module is out of control, opening a cooked bean discharging motor and executing equipment protection operation at the same time. The beans which are not baked are timely controlled to be taken out of the pot, the situation that the whole pot of beans are damaged due to disorder output signals of the main board is prevented, and waste of coffee beans is greatly reduced.

Owner:DONGYIYANGSHAN TECH CO LTD

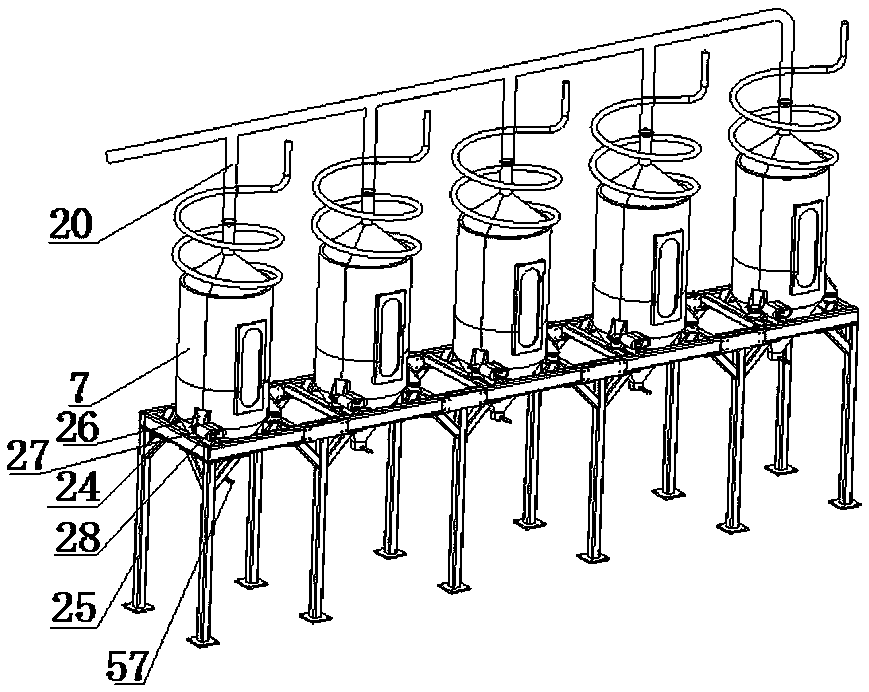

Negative-pressure coffee delivery system

PendingCN111003514AImprove delivery efficiencyReasonable structure layoutBulk conveyorsProcess engineeringMechanical engineering

The invention relates to a negative-pressure coffee delivery system. The system comprises a plurality of negative-pressure coffee delivery units connected in parallel. Each negative-pressure coffee delivery unit comprises a coffee baking machine. A first discharging port of each coffee baking machine is connected with a first feeding port in the top of a material bin feeding table. A material suction port in the top of each material bin feeding table is connected with a second feeding port of a material bin through a material bin feeding pipeline. The portion under a second discharging openingin the bottom of each material bin corresponds to a third feeding opening in the top of a bar counter feeding table. A main bar counter material suction opening in the top of each bar counter feedingtable is connected with a third feeding port in a main bar counter storage device through a main bar counter suction pipeline. A secondary bar counter suction port in the top of each bar counter feeding table is connected with a fourth feeding port in a secondary bar counter storage device through a secondary bar counter suction pipeline. The negative-pressure coffee delivery system has the beneficial effects of being reasonable in structural layout, free of pollution in the delivery process, intelligent in control and capable of greatly improving the delivery efficiency of coffee beans.

Owner:南阳东亿机械设备有限公司

Efficient and energy-saving flameless tail gas treatment device

InactiveCN111672296AEasy to operateHigh degree of automationGas treatmentDispersed particle filtrationAutomatic controlControl system

The invention discloses an efficient and energy-saving flameless tail gas treatment device comprising an air blower, a ceramic heating box, a gas distribution box, a buffer box and a tail gas pretreatment box; a gas inlet port of the air blower is connected to a gas outlet port of the tail gas pretreatment box through a connecting bent pipe I; a gas inlet port of the tail gas pretreatment box is fixedly connected with a coffee baking machine tail gas exhaust pipe; a control valve I is fixedly arranged on the coffee baking machine tail gas exhaust pipe; an air outlet port of the air blower is fixedly connected to a gas inlet port of the gas distribution box; the interior of the gas distribution box is of a cavity structure, and a ceramic heating bed is fixedly arranged in the cavity of thegas distribution box. The tail gas treatment device is simple in structure and high in automation degree; an automatic control system is arranged, the whole operation process of a boiler is automatically controlled, operation of the boiler is greatly simplified, efficient and high-quality operation and automatic alarming are guaranteed, operation safety is guaranteed, and operation cost and operation labor intensity are greatly reduced.

Owner:昆山亿政咖啡有限公司

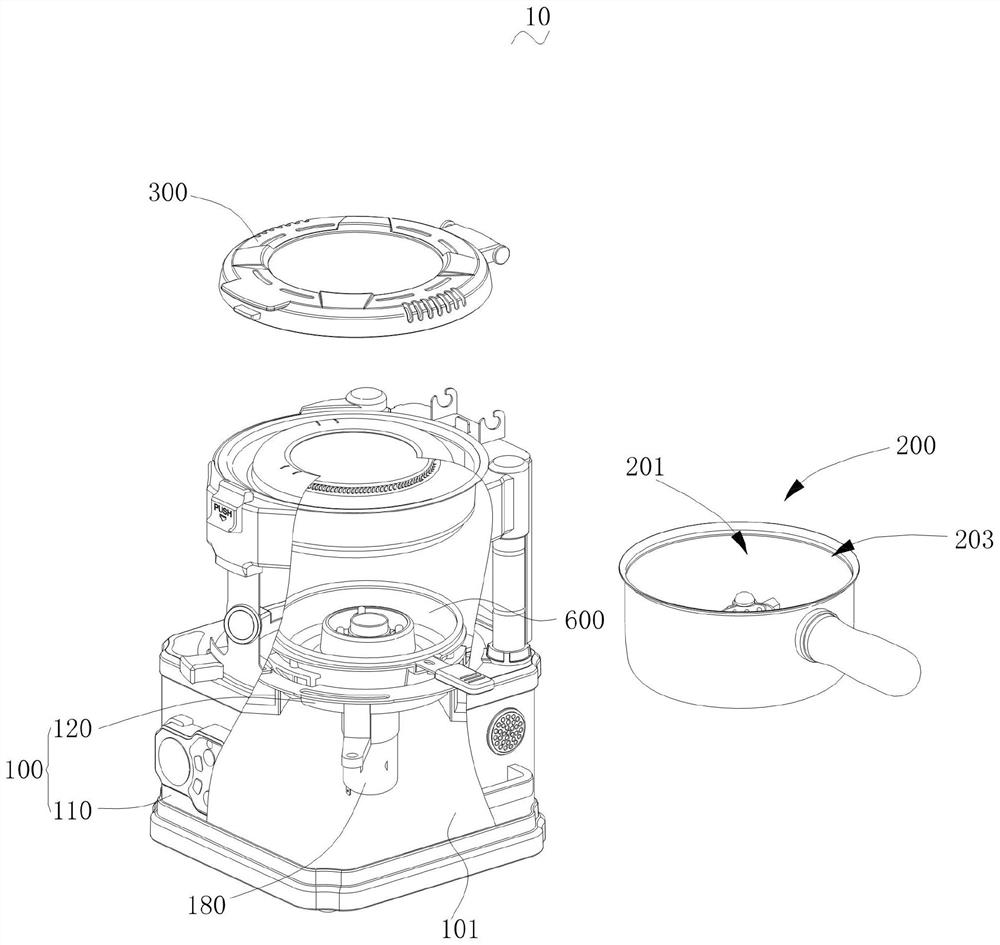

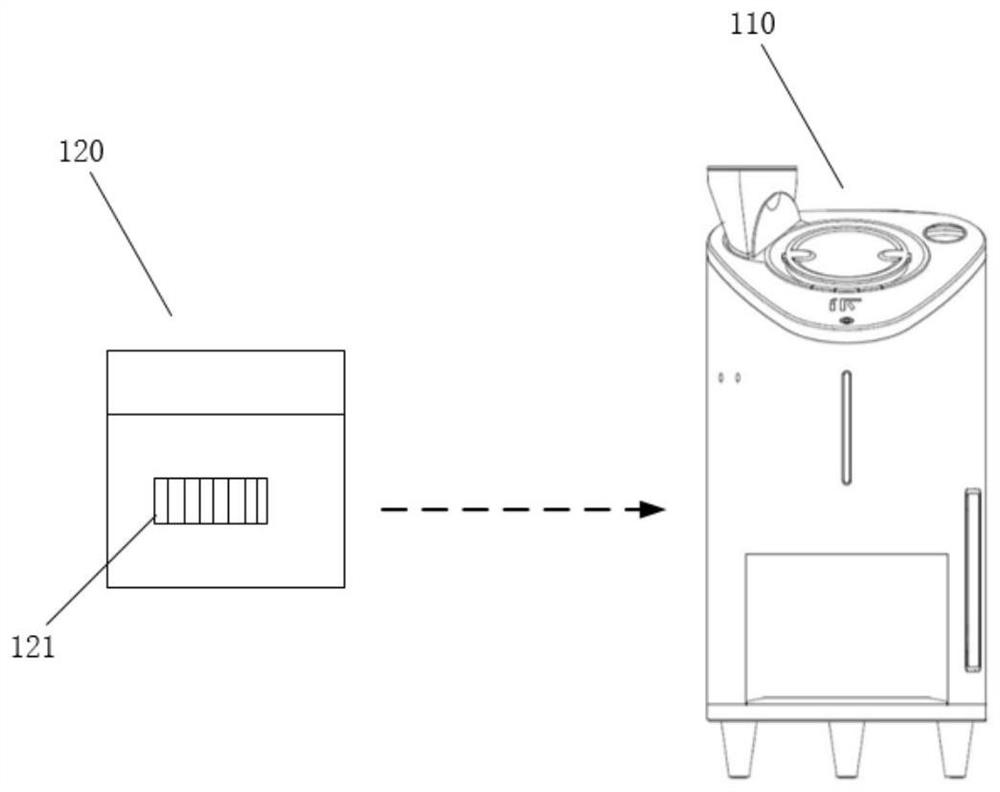

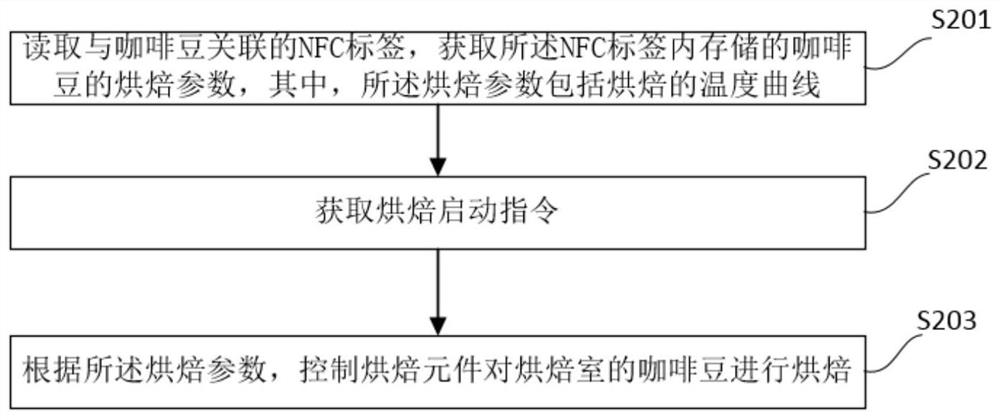

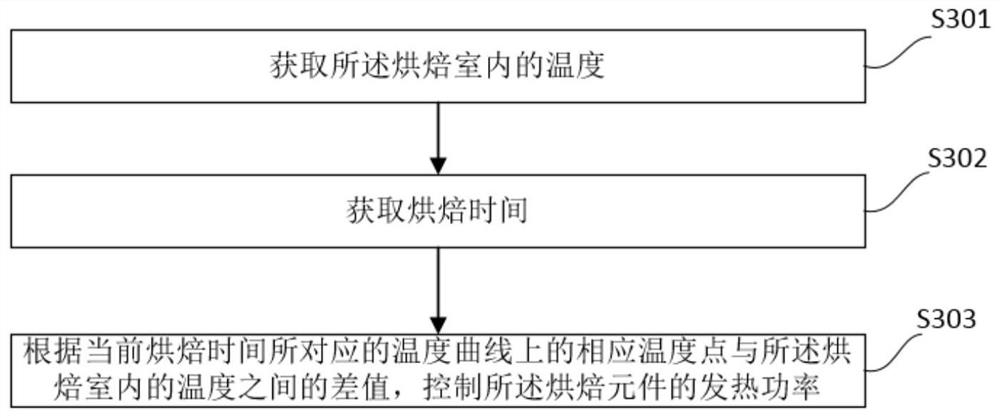

Coffee roasting method and device, storage medium, coffee roaster

The invention relates to a coffee roasting method and device, a storage medium, and a coffee roaster. The coffee roasting method of the present invention includes the following steps: reading the NFC tag associated with the coffee beans, and obtaining the roasting parameters of the coffee beans stored in the NFC tags, wherein the roasting parameters include a roasting temperature curve; obtaining A roasting start instruction; according to the roasting parameters, the roasting elements are controlled to roast the coffee beans in the roasting chamber. The coffee roasting method of the present invention reads the roasting parameters stored in the electronic tag associated with the coffee beans, and roasts the coffee beans according to the roasting curve in the parameters, which makes the roasting process more convenient and improves the quality of roasted coffee. Bean quality stability.

Owner:INNOROMA PTE LTD

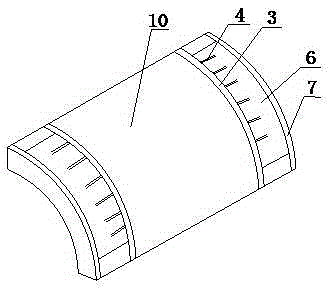

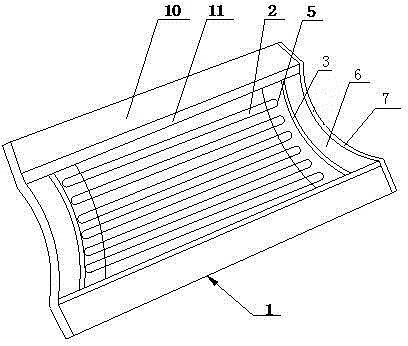

A heating mechanism of a coffee roaster and a processing process thereof

ActiveCN105310087AExtended service lifeReduce the probability of burning outFood treatmentElectricityEngineering

The invention relates to a heating mechanism of a coffee roaster and a processing process thereof. The heating mechanism of a coffee roaster comprises more than one arc-shaped heating base arranged on the outer periphery side of a roasting oven. A U-shaped notch extending inward is formed in each of the two ends of each heating base; an arc-shaped vertical base used for supporting heating tubes is welded to the inner wall of each heating base and is close to each U-shaped notch; a plurality of transverse heating tubes are arranged in the circumferential direction in each heating base at intervals; the two ends of each heating tube are put on the vertical bases; the distance between the two vertical bases is less than or equal to the length of each heating tube; each vertical base is circumferentially provided with through holes in a matching penetration relationship with the heating tubes. The heating mechanism also comprises guide wires arranged at the ends of the heating tubes and electrically connected with the heating tubes. The guide wires penetrate through the through holes and extend to the outsides of the vertical bases. The roasting oven and the guide wires are arranged on the inner space and the outer space of the heating bases and are isolated, so that the probability of burnout of the guide wires is reduced and the service life of the heating tubes is prolonged.

Owner:FUJIAN AGRI & FORESTRY UNIV

Smokeless coffee baking machine and processing method

PendingCN113826927AKeep the flavorIn line with the pursuit of modern green productionFood treatmentProcess engineeringAir blower

The invention discloses a smokeless coffee baking machine and a processing method. The smokeless coffee baking machine comprises a baking machine body, and the baking machine body comprises a funnel, a baking chamber, a circulating air blower, a cyclone separator, a control device and a cooling disc; the funnel and the circulating air blower are respectively arranged on the baking chamber, and the cyclone separator is arranged on the circulating air blower. The processing method comprises the following steps: step 1, completing exhausting and purging, step 2, baking: after exhausting and purging are completed and a valve is closed, a burner works to preheat a baking chamber, and when the temperature of the baking chamber meets the baking requirement, coffee beans are heated and put into the baking chamber from a hopper to be baked; smoke and particle impurities can be removed when coffee beans are roasted, the original flavor of the coffee beans is guaranteed, smokeless roasting processing of the coffee beans is basically achieved, the pursuit of modern green production is met, and the smokeless coffee bean roasting device is worthy of application and popularization.

Owner:王力咖啡(上海)有限公司

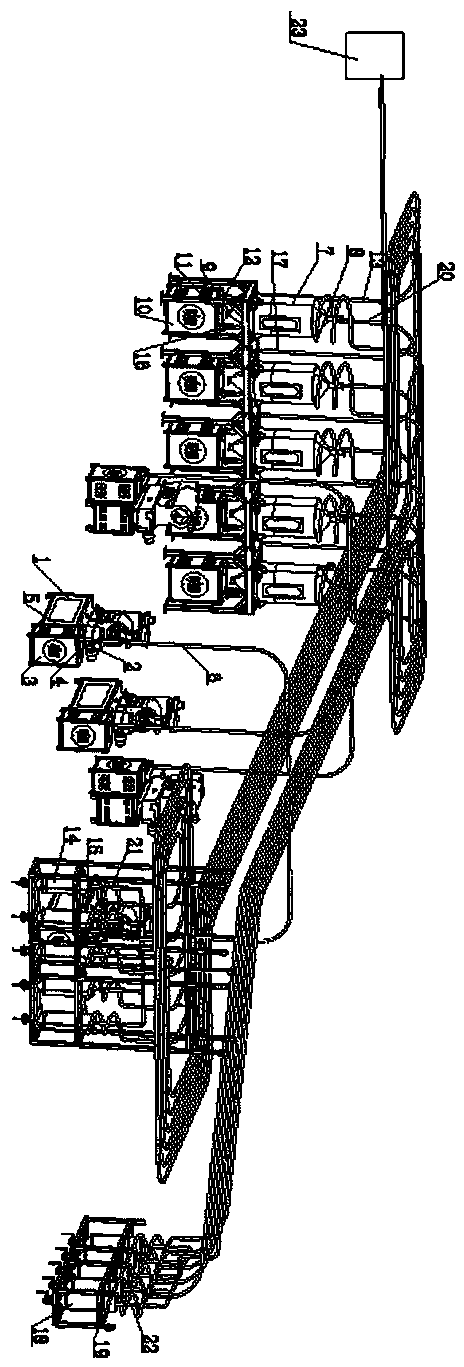

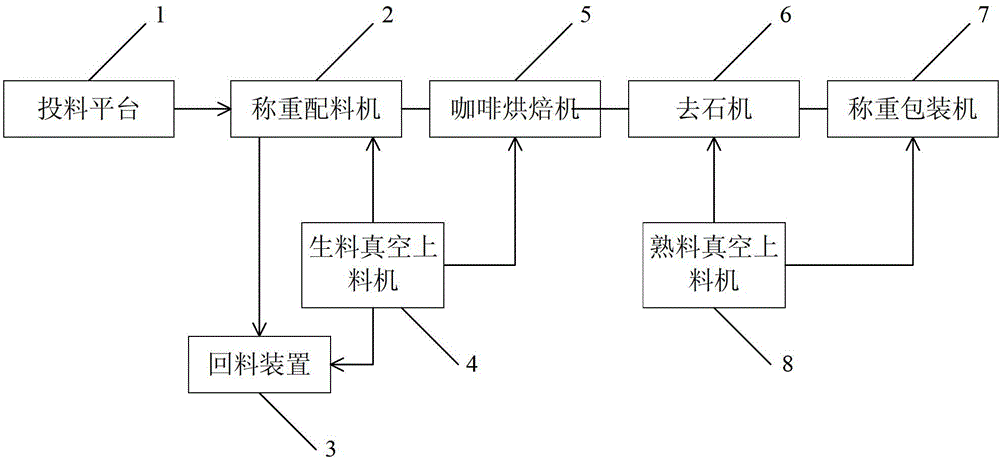

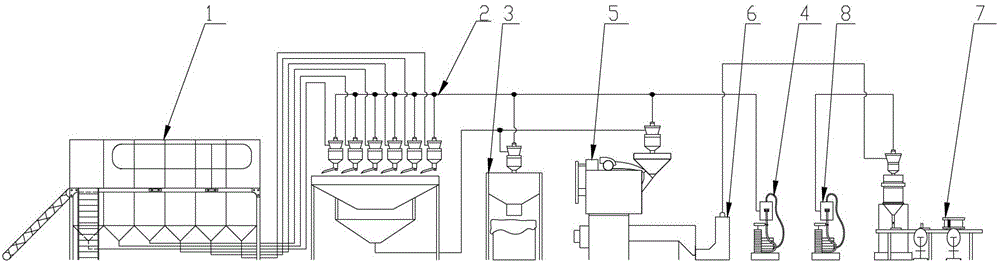

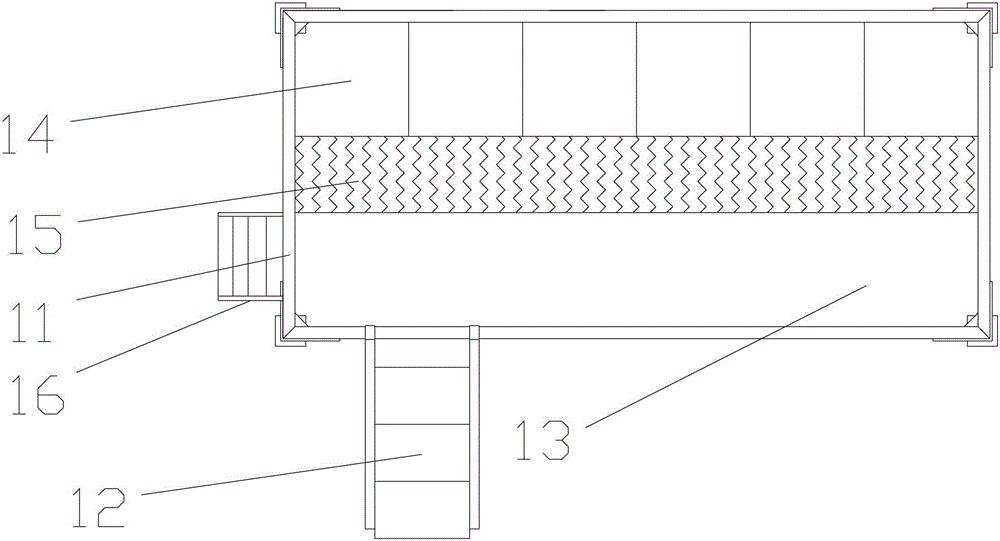

Automatic coffee production line with bin-free continuous material feeding

InactiveCN103330037BLess investmentSmall footprintBeverage vesselsSolid materialProduction lineCoffee processing

The invention provides an automatic coffee production line with bin-free continuous material feeding. The automatic coffee production line comprises a material feeding platform, a weighing and proportioning machine, a coffee baking machine, a stone removing machine and a weighing packaging machine, which are connected with one another in sequence, and further comprises vacuum feeding machines and a controller, wherein the controller is in control connection with the vacuum feeding machines; the vacuum feeding machines comprise a vacuum raw material feeding machine and a vacuum cured material feeding machine; the material feeding platform, the weighing and proportioning machine and the coffee baking machine are in control connection through the vacuum raw material feeding machine; the stone removing machine and the weighing packaging machine are in control connection through the vacuum cured material feeding machine. Compared with the prior art, the automatic coffee production line with bin-free continuous material feeding is small in investment, small in occupied land, simple and convenient to mount, flexible to operate, sanitary and clean, saves a lot of manpower, replaces an imported product and has prospect of earning foreign exchange through exports.

Owner:SHANGHAI AODONG LOGISTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com