Coffee bean refined baking method, system and equipment

A technology for refined roasting and coffee beans, which is applied in transmission systems, electrical components, food science, etc., and can solve the problems of poor coffee roasting data collection and processing, inability to achieve refined roasting operations, and insufficient taste to fully meet requirements. , to achieve a good human-computer interaction effect, improve the coffee roaster and control system, and improve the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

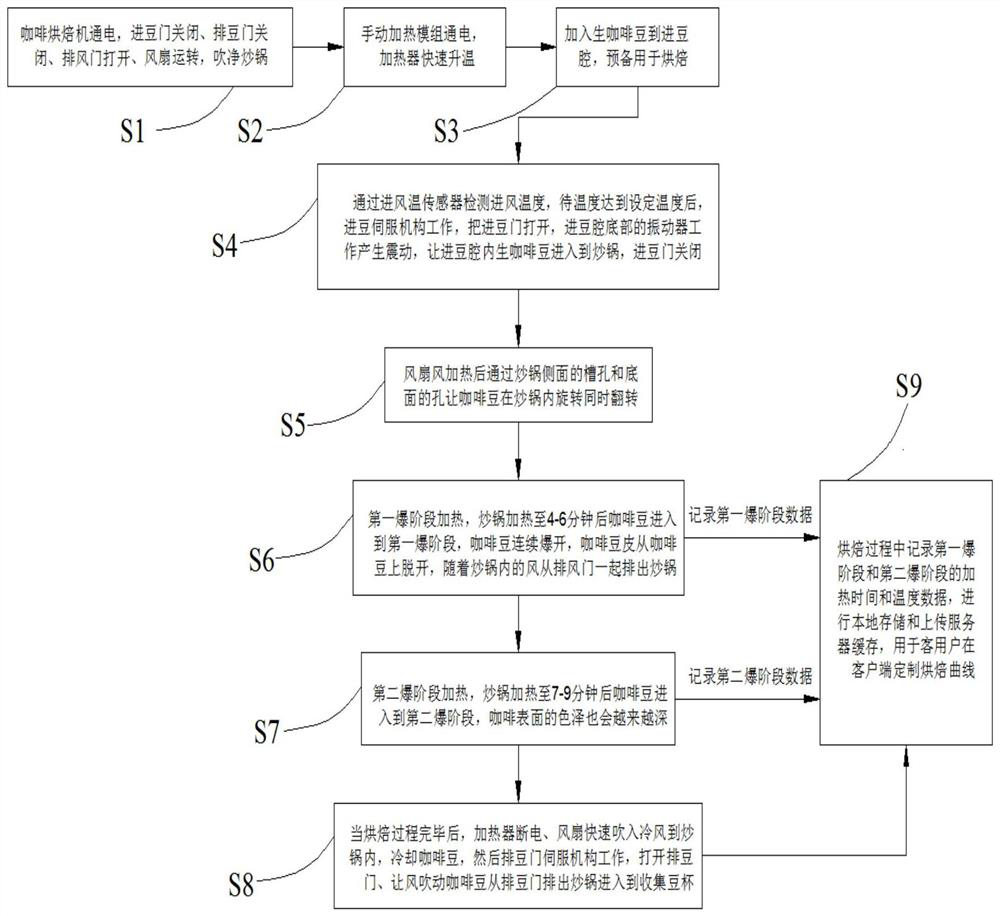

[0066] Example 1, refer to figure 1 , which is an embodiment of the present invention, which provides a method for refining and roasting coffee beans, which specifically includes the following steps:

[0067] S1, the coffee roasting machine is powered on, and the bean inlet door is closed, the bean discharge door is closed, the exhaust door is opened, the fan 1 is turned on, and the wok 13 is blown out in advance;

[0068] S2, through the manual control panel 108, the heating module is powered on, and the heating ring 2 in the coffee roaster rapidly heats up;

[0069] S3, add green coffee beans into the bean cavity, ready for roasting;

[0070] S4, the inlet air temperature is detected by the inlet air temperature sensor 6. After the temperature reaches the set temperature, the bean inlet door servo mechanism 3 works to open the bean inlet door. The raw coffee beans in the cavity enter into the wok 13, and the bean inlet door is closed after completion;

[0071] S5, the win...

Embodiment 2

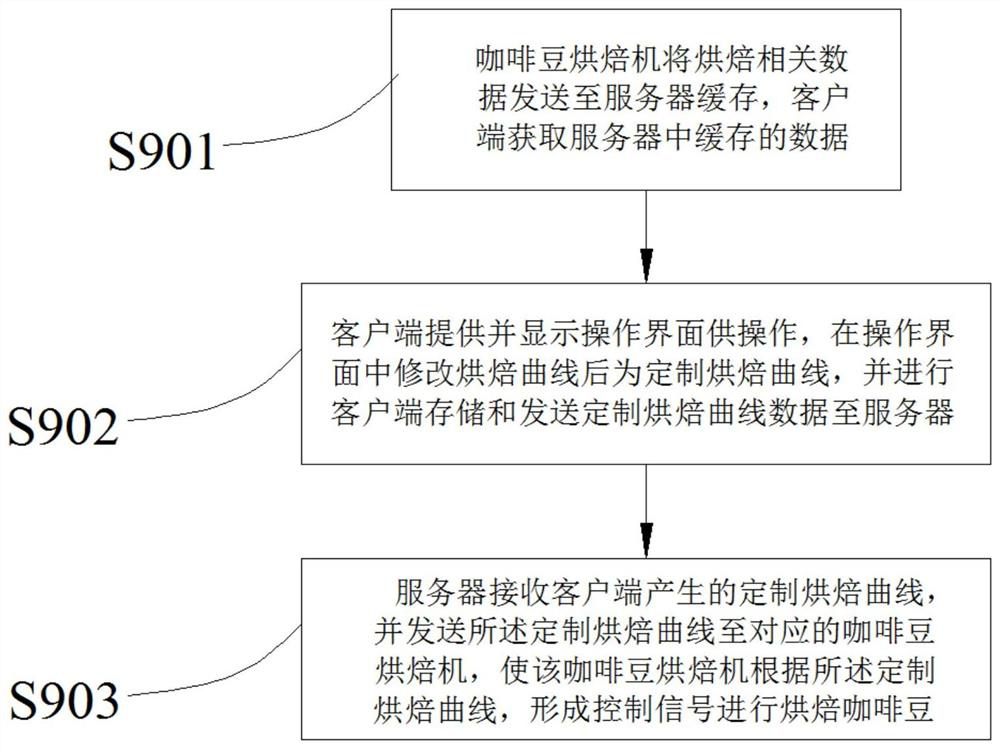

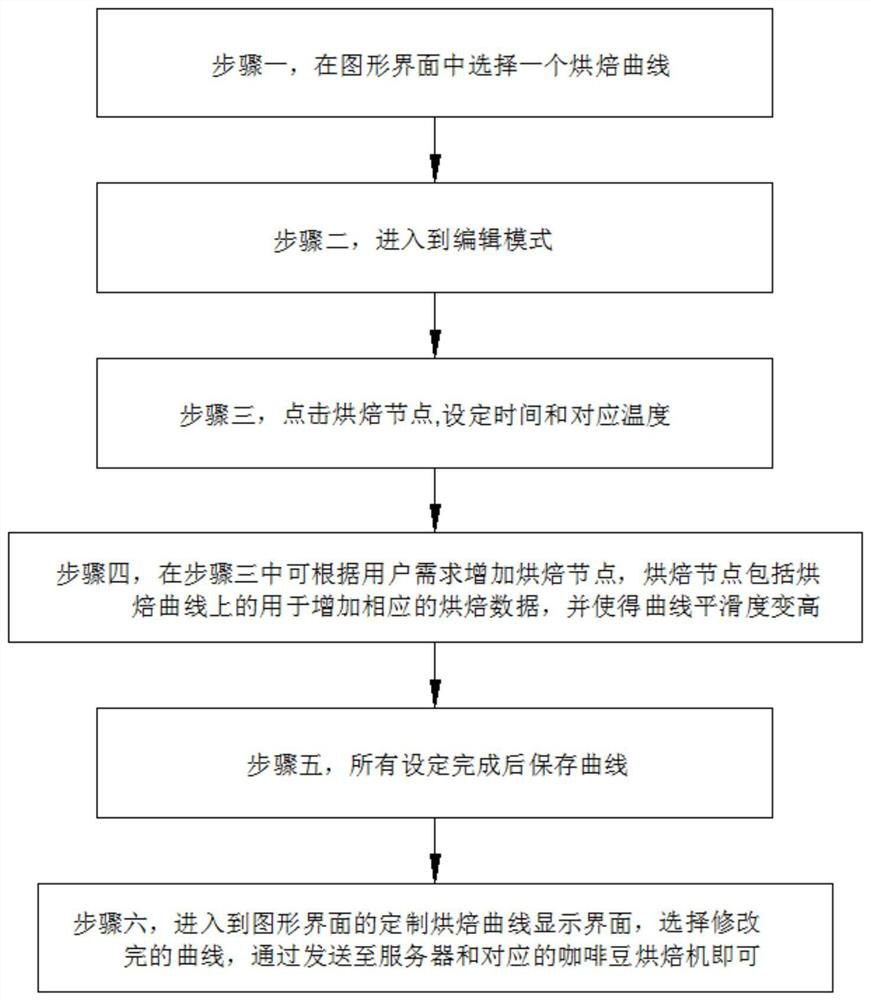

[0093] Example 2, refer to Figure 5 , this embodiment is a system for a method for refining and roasting coffee beans, including a built-in circuit for controlling the coffee roaster, a control panel 108 for controlling the built-in circuit, and a power supply module 106 for the overall power supply of the coffee roaster , a server for data transmission and caching, and a client 20 for operation; the client 20 obtains server cache information and sends customized roasting curve data to the server; the coffee roaster receives the server's requirements for adjusting the roasting curve and provides roasting-related data sent to the server. This built-in circuit described further includes:

[0094] The sensor device receiving module 102 is used for receiving data collected by the sensor;

[0095] a control module 103 for controlling electrical components in the coffee roasting machine;

[0096] The processing module 101 is set as the main control MCU, which is used for the dat...

Embodiment 3

[0102] Example 3, refer to Image 6 and Figure 7 , this embodiment is a device for a method or system for refining and roasting coffee beans, including a coffee roasting machine body, a fan 1 that generates airflow upwards is arranged below the inner cavity of the coffee roasting machine body, and above the fan 1 There is a heating ring 2, a frying pan 13 is arranged above the heating ring 2, a bean inlet door servo mechanism 3 is arranged above the frying pan 13 for the control of the bean inlet door, and the lower part of the frying pan 13 is arranged for the bean discharge door control. The bean discharge door servo mechanism 4 and the air discharge door servo mechanism 5 for the control of the air discharge door, and the frying pan 13 is provided with a frying pan temperature sensor 7 outside, and the air inlet end of the frying pan 13 is provided with an air inlet temperature sensor 6 , the frying pan 13 is provided with a bean temperature sensor 8 . The discharge end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com