Automatic coffee production line with bin-free continuous material feeding

A production line and coffee technology, which is applied to coffee, solid materials, beverage preparation devices, etc., can solve the problems of high cost and low utilization rate of imported large equipment, and achieve the effects of small investment, manpower saving and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

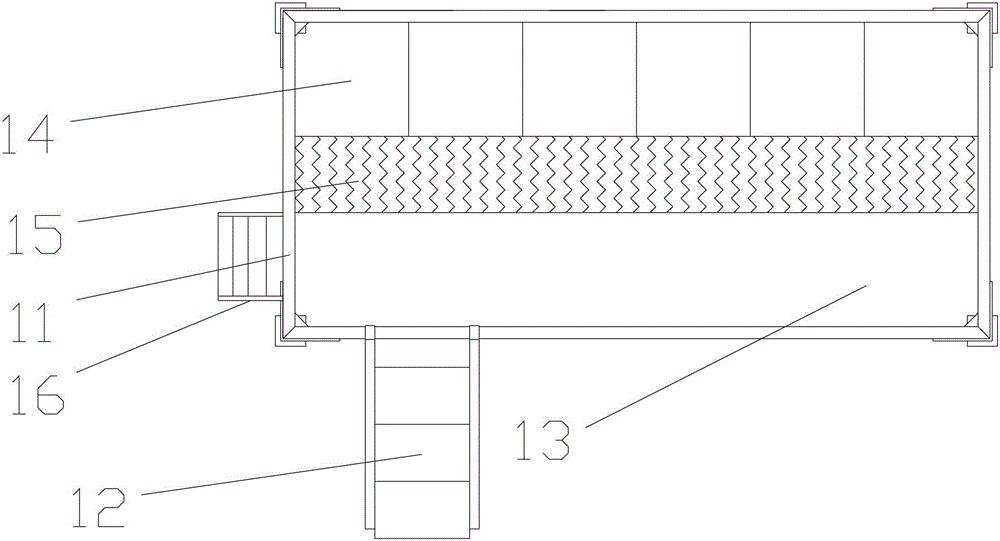

[0023] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

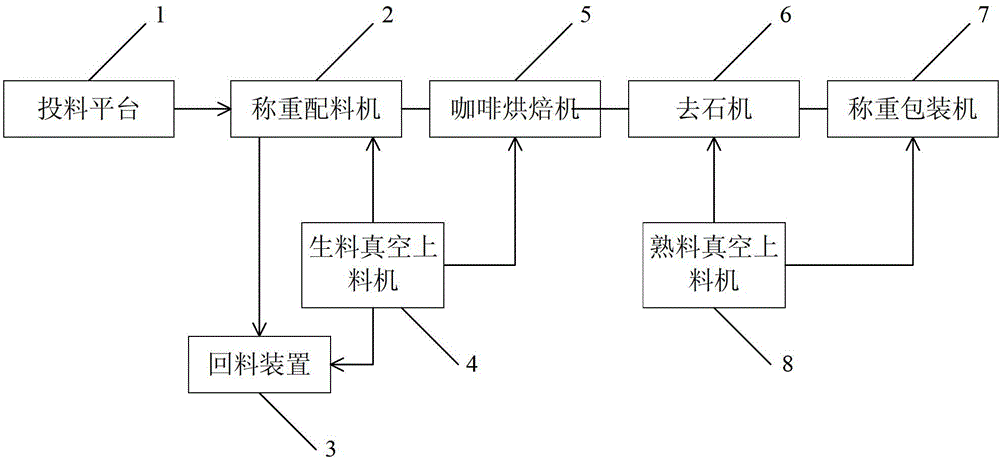

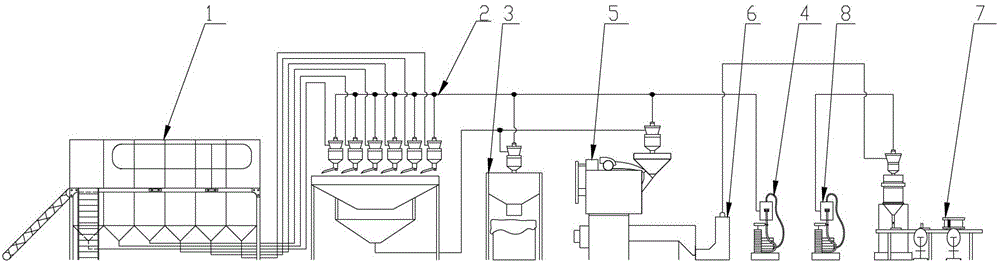

[0024] see figure 1 and figure 2 , as shown in the figure, the warehouseless continuous feeding automatic coffee production line mainly lies in that this technology does not use the traditional grain material warehouse. Machine 6, weighing packaging machine 7, also comprise vacuum feeder, controller, described controller is connected with vacuum feeder control, and described vacuum feeder comprises raw material vacuum feeder 4, clinker The vacuum feeder 8, the feeding platform 1, the weighing batching machine 2, and the coffee roaster 5 are controlled and connected through the raw material vacuum feeder 4, and the stone removal machine 6 and the weighing packaging machine 7 are connected through the clinker Vacuum feeder 8 control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com