A heating mechanism of a coffee roaster and a processing process thereof

A heating mechanism and baking machine technology, applied in application, food processing, food science and other directions, can solve problems such as easy burnout of wires, and achieve the effects of reducing heat transfer, reducing the probability of burning out, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

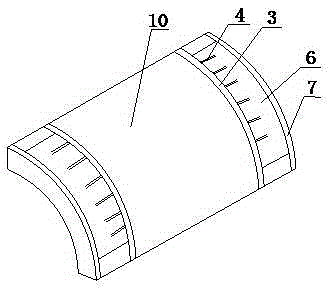

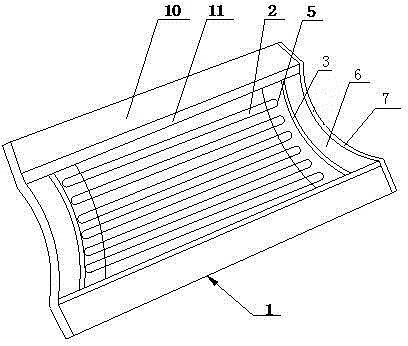

[0022] like Figure 1~2 As shown, the heating mechanism of a coffee roaster according to the embodiment of the present invention includes more than one arc-shaped heating seat 1 respectively arranged on the outer peripheral side of the roasting furnace. An arc-shaped stand 3 for supporting the heating tube 2 is welded on the inner wall of the heating seat 1 and close to the notch; Two horizontal heating tubes 2, the two ends of the heating tube 2 are erected on the uprights 3 respectively, the distance between the two uprights 3 is less than or equal to the length of the heating tubes 2; the uprights 3 are circumferentially spaced There is a through hole 5 corresponding to the heating tube 2; it also includes a wire 4 located at the end of the heating tube 2 and electrically connected to it, and the wire 4 passes through the through hole 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com