Smokeless coffee baking machine and processing method

A processing method and baking machine technology, applied in the fields of application, food processing, food science, etc., can solve the problems of purifying and removing smoke without smoking and defogging functions, no ventilation, a large amount of smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

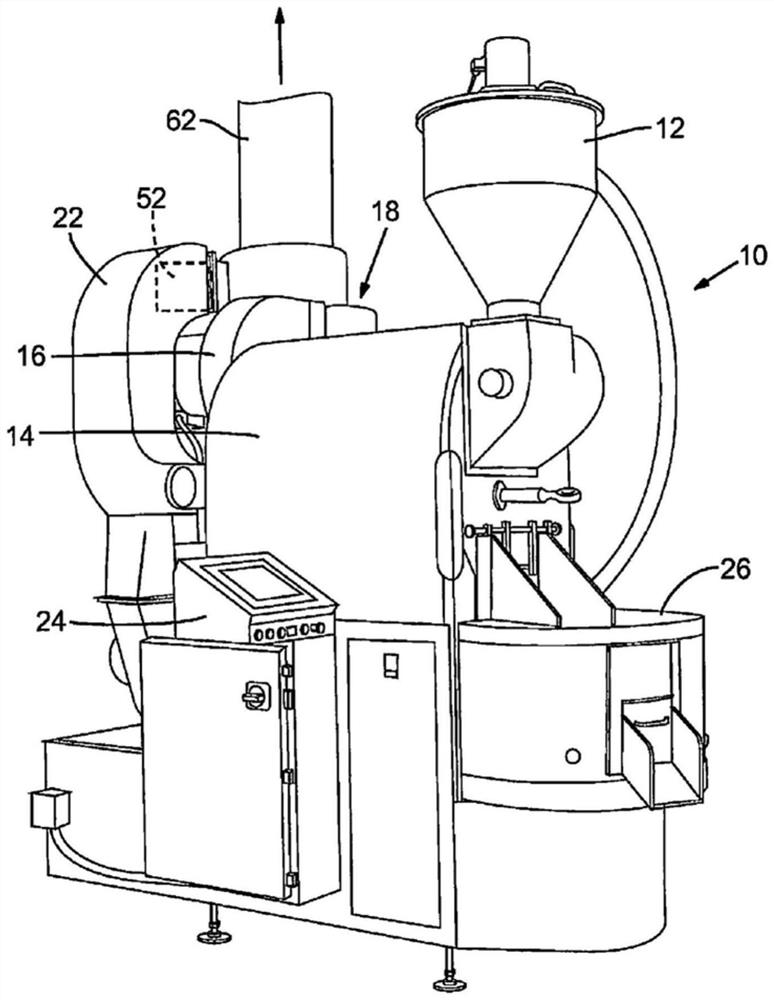

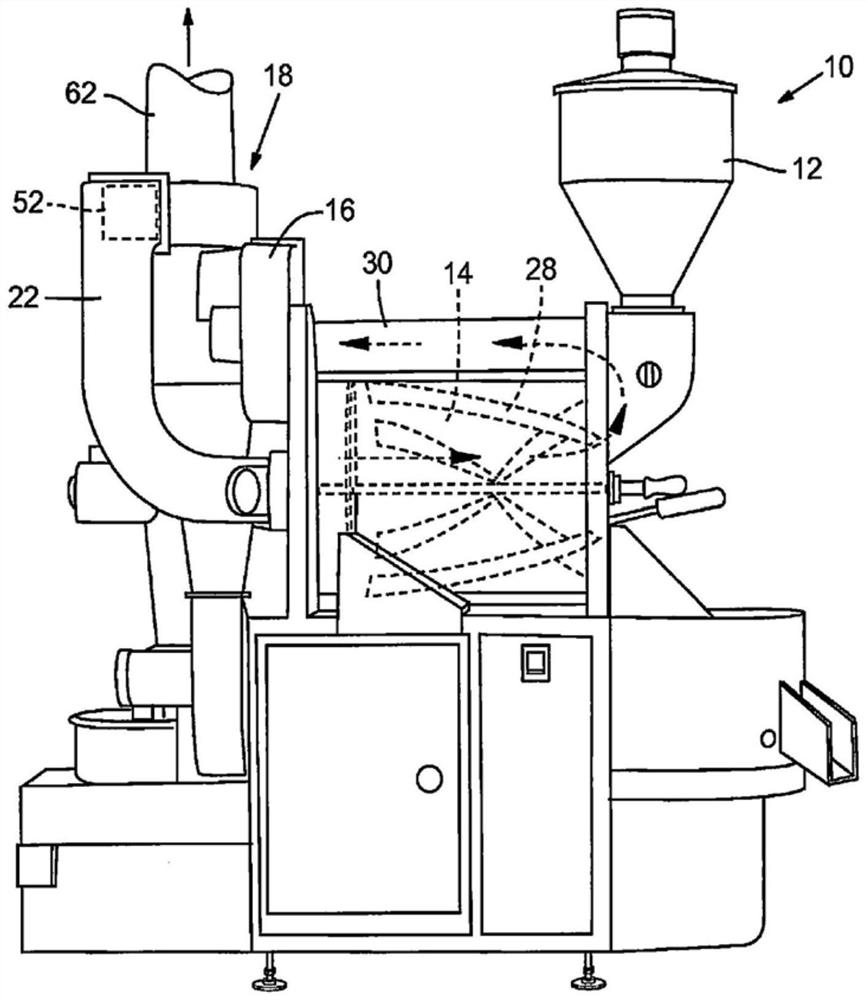

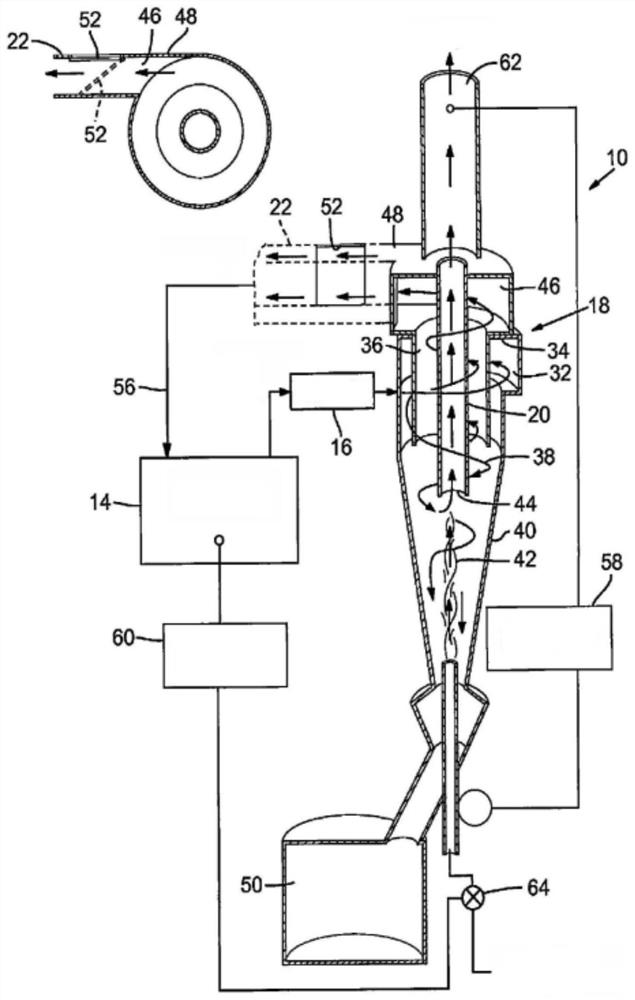

[0038] Such as Figure 1-Figure 5 As shown, a smokeless coffee roaster includes a roaster body 10, and the roaster body 10 includes a hopper 12, a roasting chamber 14, a circulating blower 16, a cyclone separator 18, a control device 24 and a cooling plate 26;

[0039] The funnel 12 and the circulation blower 16 are respectively arranged on the baking chamber 14, the cyclone separator 18 is arranged on the circulation blower 16, the control device 24 is arranged on one side of the roaster body 10, and the cooling plate 26 is arranged on the bottom of the baking chamber 14;

[0040] The outlet 48 of the cyclone separator 18 is provided with a first pipeline 22 for exhausting the roasting chamber 14, the inside of the cyclone separator 18 is provided with an incineration pipe 20, and the inside of the roasting chamber 14 is provided with screening blades for coffee bean screening 28. The baking chamber 14 communicates with the circulation blower 16 through the second pipeline 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com