Automatic-circulation baking oven for sheet type printing material

A technology of printing materials and automatic circulation, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of long baking time, long baking area of the furnace body, and large area of the baking furnace, etc., to achieve Reduced space, increased automation, and improved baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

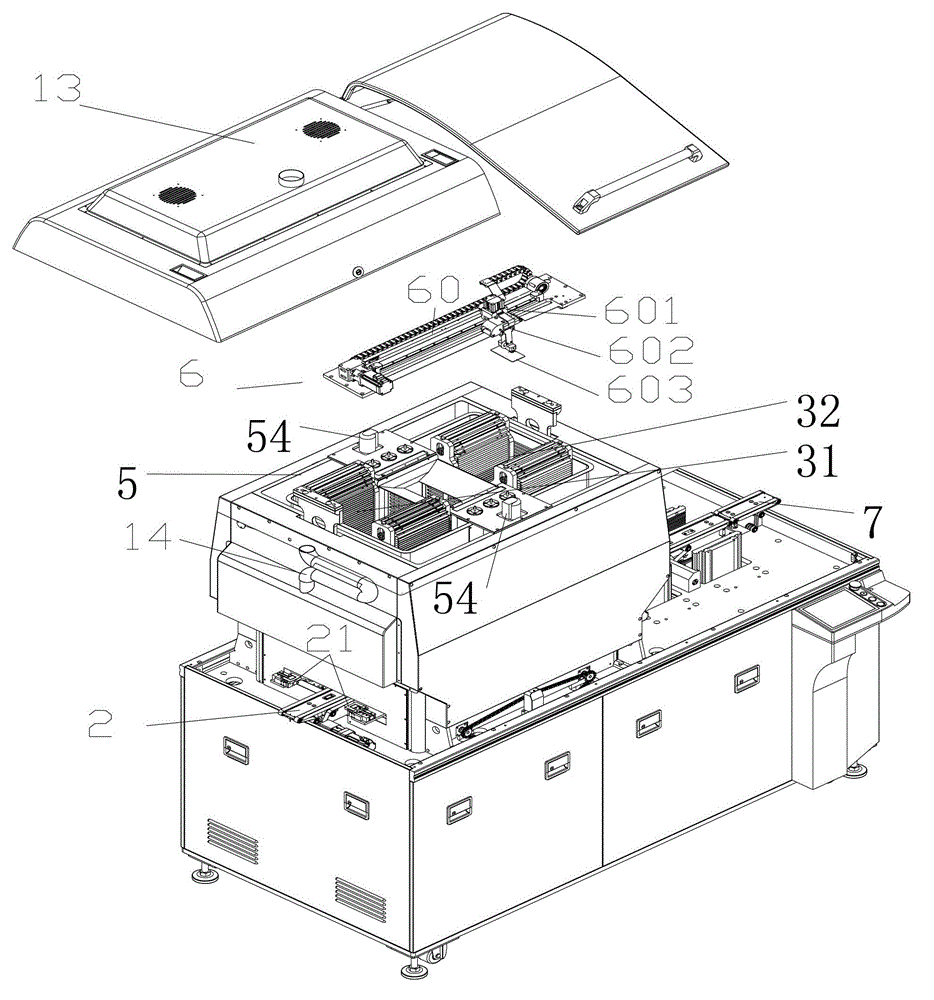

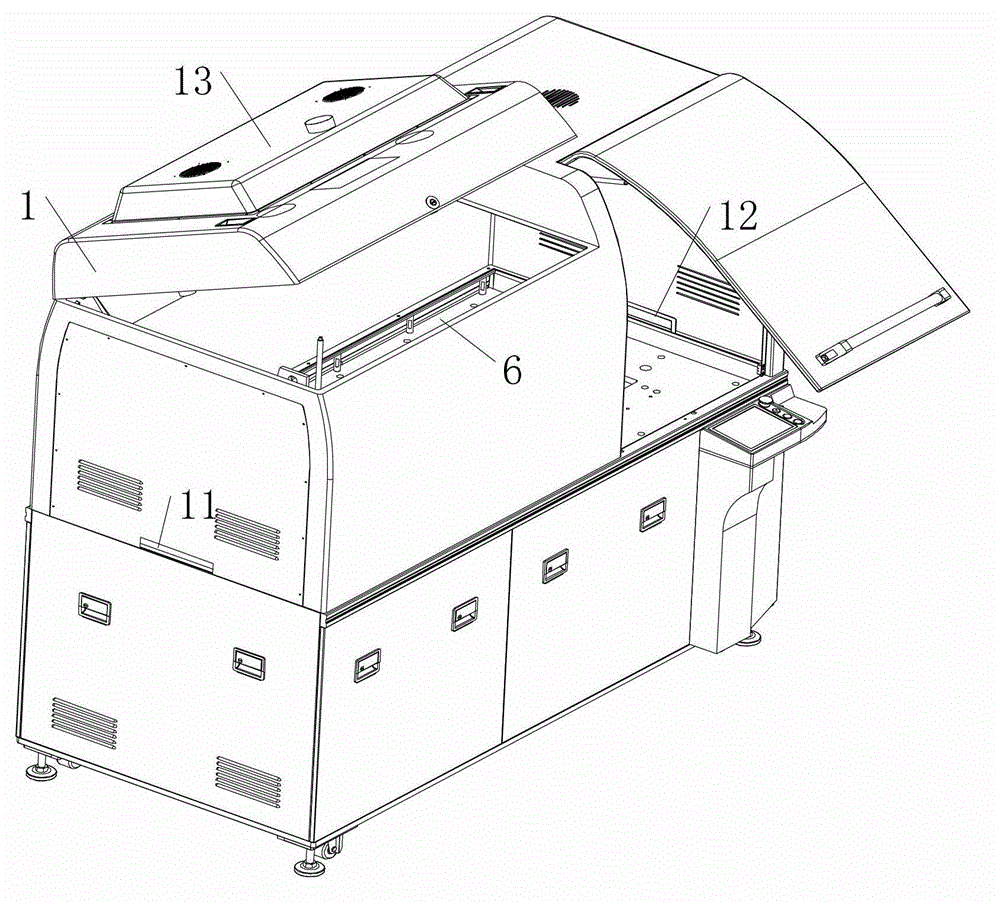

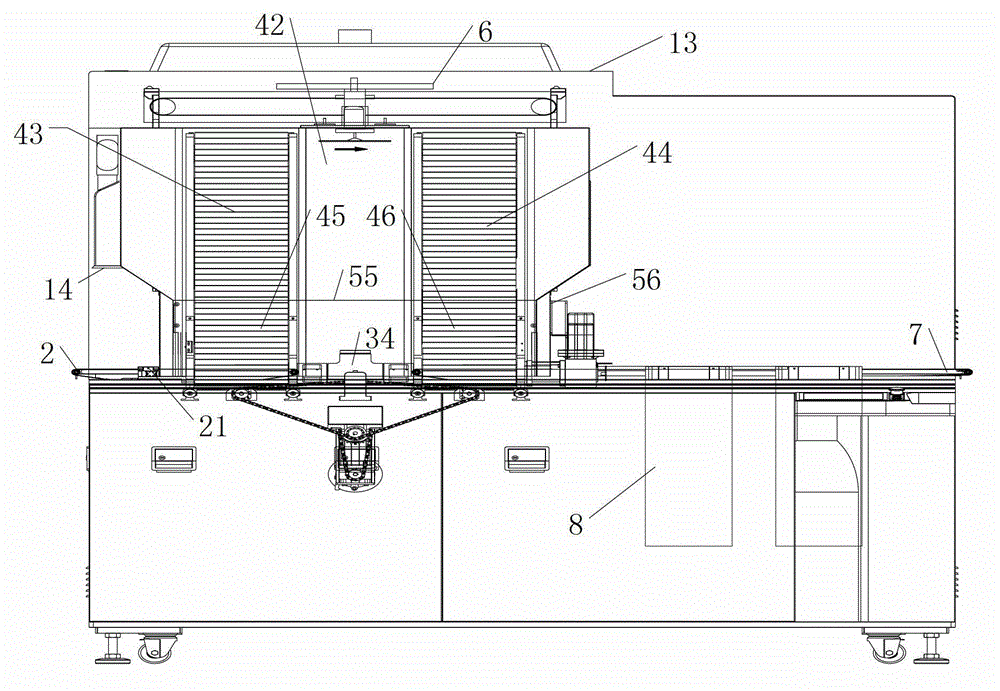

[0028] An embodiment of the present invention provides an automatic cycle baking oven for thin-plate printing materials, which combines Figure 1 to Figure 6 As shown, it includes: a housing 1, a feeding device 2, a material rack 3, a heating device 4, a hot air duct 5, a material transfer device 6 and a discharging device 7; one side of the housing 1 is provided with a feeding port 11 and the other The side is provided with a discharge port 12, and the material rack 3, the heating device 4, the hot air duct 5 and the material transfer device 6 are arranged in the housing 1; the material rack 3 includes a feed rack 31 and a discharge rack 32, and the feed rack 31 and The discharge racks 32 all have holders for holding the material 10, which are respectively used to send the material 10 from the lower end of the feed rack 31 to the upper end of the feed rack, and send the material 10 from the upper end of the discharge rack 32. To the lower end of the discharge rack; the hot ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com