Laminated pin type oven for flue-cured tobaccos

A baking oven and lamination technology, applied in the application, tobacco, tobacco preparation and other directions, achieves the effects of reducing labor intensity, simple structure, improving baking efficiency and baking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

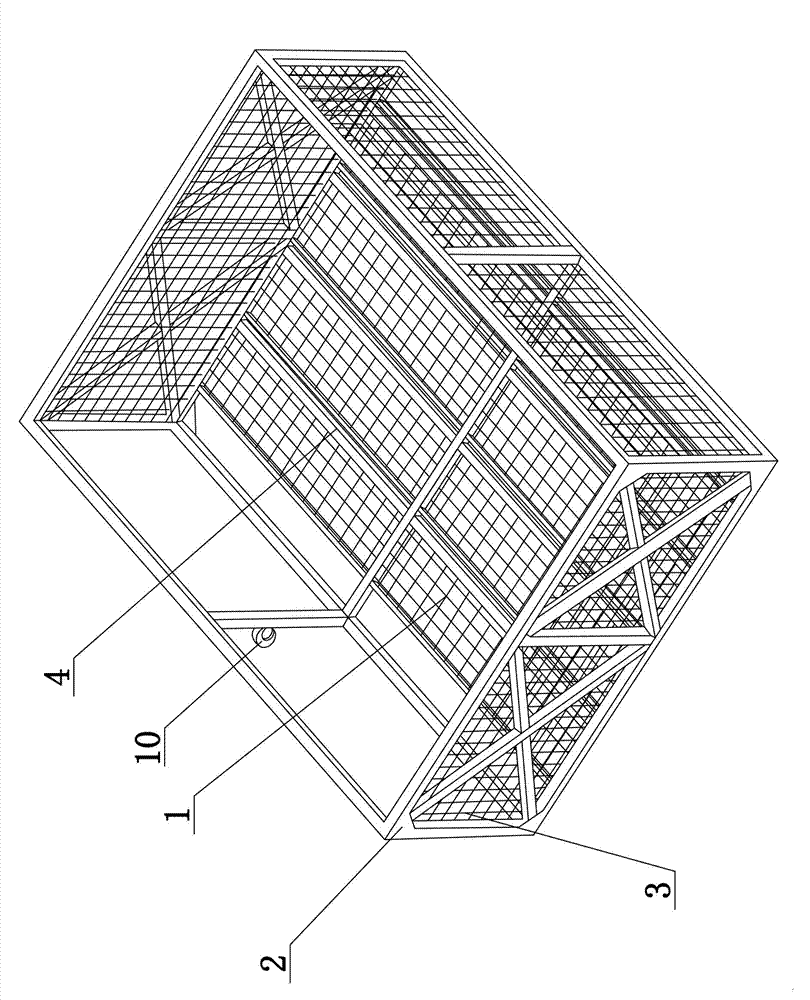

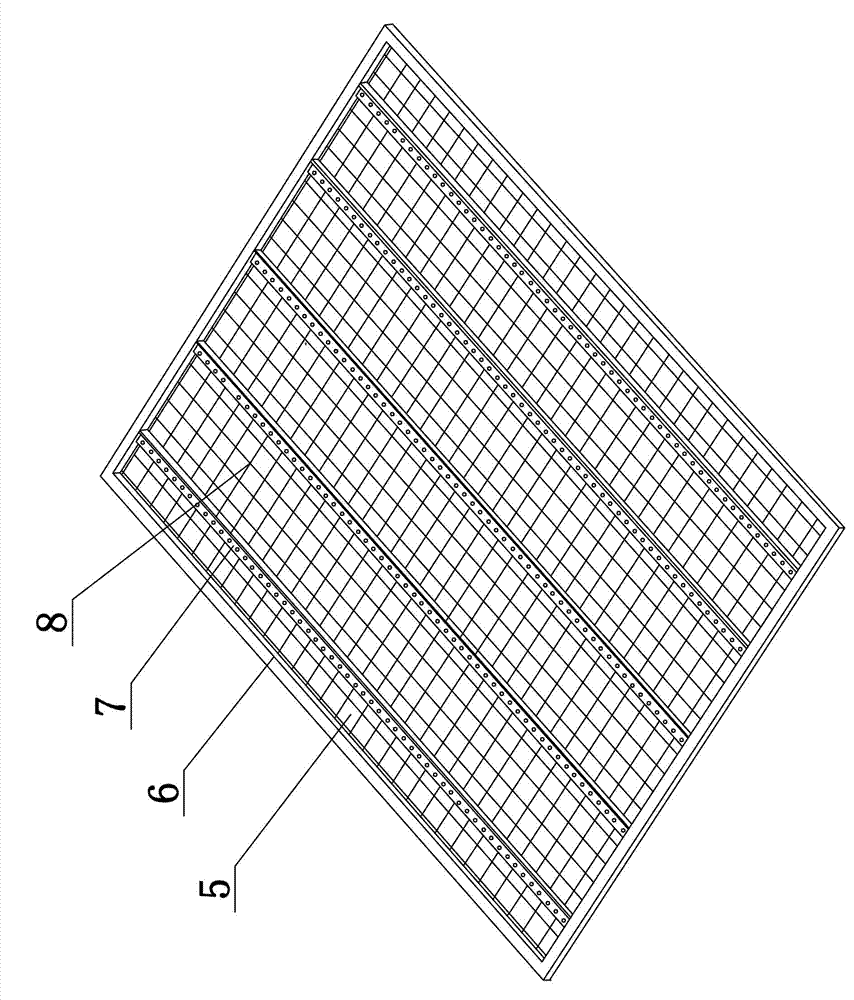

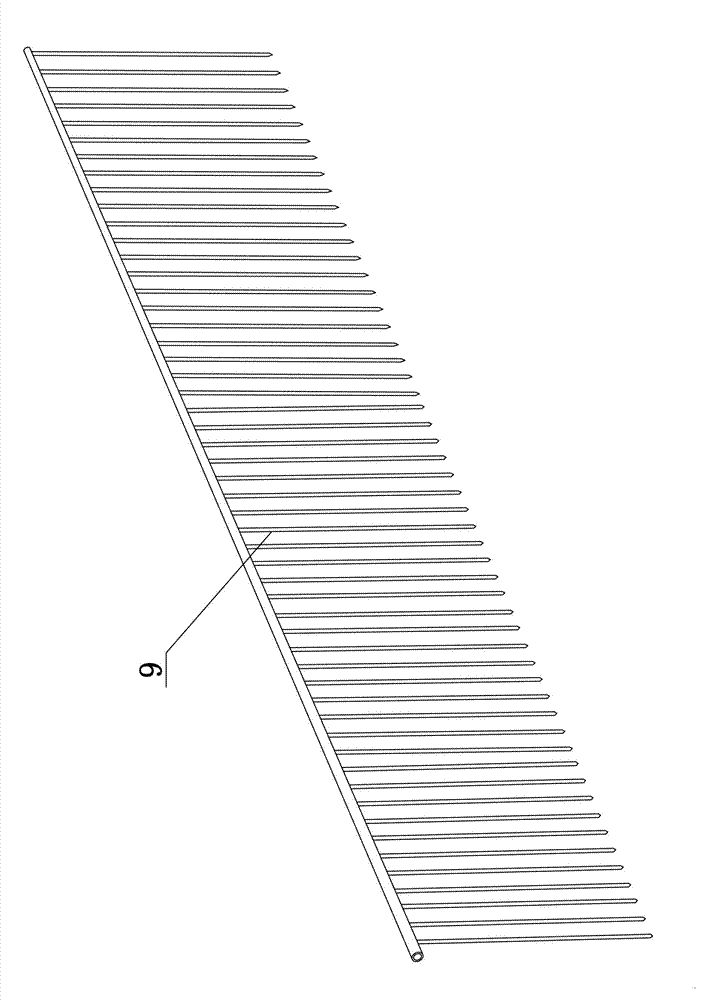

[0032] Such as figure 1 , 2 , 3, and 4, a laminated needle-inserted baking oven for flue-cured tobacco, comprising a frame body 1, a frame cover plate 5 and pins 9, the frame body 1 is a gas-permeable tetragonal structure with side openings, and the A suspension ring 10 is provided on the top surface of the frame body 1 . The frame cover plate 5 is covered on one side of the opening of the frame body 1, the side of the frame body 1 opposite to the frame cover plate 5 and the frame cover plate 5 are provided with corresponding pinholes, and the tobacco leaves are interleaved and stacked in the frame body 1 , the pin 9 passes through the pinhole and the tobacco leaves in the frame 1. The pin 9 is a steel needle group composed of a plurality of steel needles. The frame 1 includes a skeleton 2, a breathable mesh 3 and a load-bearing plate 4. The skeleton 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com