Automatic displacement feeding, baking and cooling device and method

A technology of cooling device and displacement, which is applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of high equipment cost, troublesome operation, time-consuming and laborious production efficiency, etc., and achieve the improvement of baking and cooling efficiency, baking And the effect of fast cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

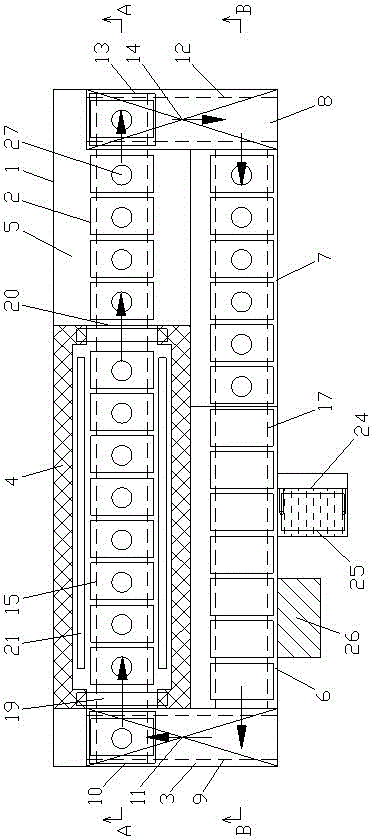

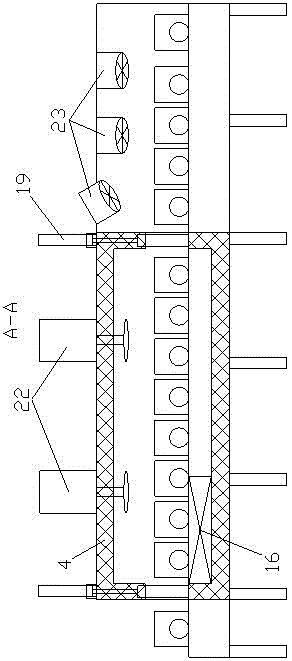

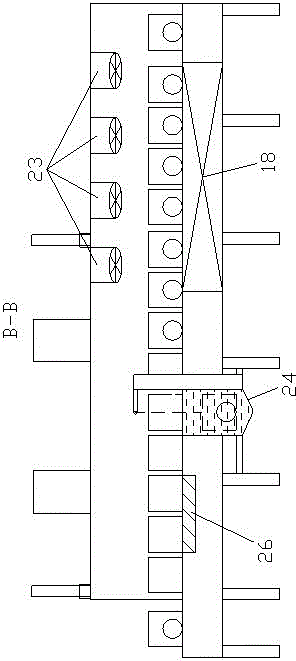

[0026] like Figure 1~3 As shown, an automatic displacement feeding baking and cooling device includes a frame 1, a feeding platform 3 for conveying a workpiece cage 2 is arranged transversely on the front of the frame 1, and a pair of workpieces is arranged longitudinally on the right side of the frame 1. The workpiece 27 in the cage 2 is baked in a drying box 4, the entrance of the front end of the drying box 4 is connected to the outlet of the feeding platform 3, and the frame 1 is provided with a pair of workpieces at the rear of the drying box 4. The workpiece 27 in the cage 2 is pre-cooled in the pre-cooling zone 5; the left side of the frame 1 is longitudinally provided with a discharge platform 6, and the rear of the discharge platform 6 is provided with a force for the workpiece 27 in the workpiece cage 2. An air-cooled cooling zone 7, the outlet at the front of the discharge platform 6 is connected to the entrance of the feed platform 3 to send back an empty workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com