Biscuit production line

A production line, biscuit technology, applied in baking, dough processing, baked food and other directions, can solve the problems of high cost, long time, large biscuit production cost, etc., achieve high integration and automation, reduce baking time, heating The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

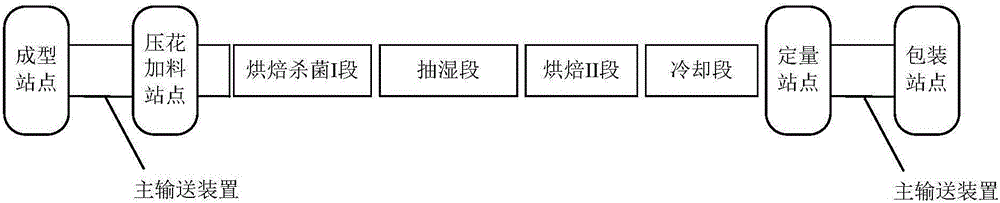

[0024] Such as figure 1 As shown, the biscuit production line according to the present invention includes successively a biscuit forming station, an embossing feeding station, a baking and sterilization section I, a dehumidification section, a baking II section, a cooling section, a quantitative station, a packaging station, and a main station operating between each station. Delivery device, and control device (not shown).

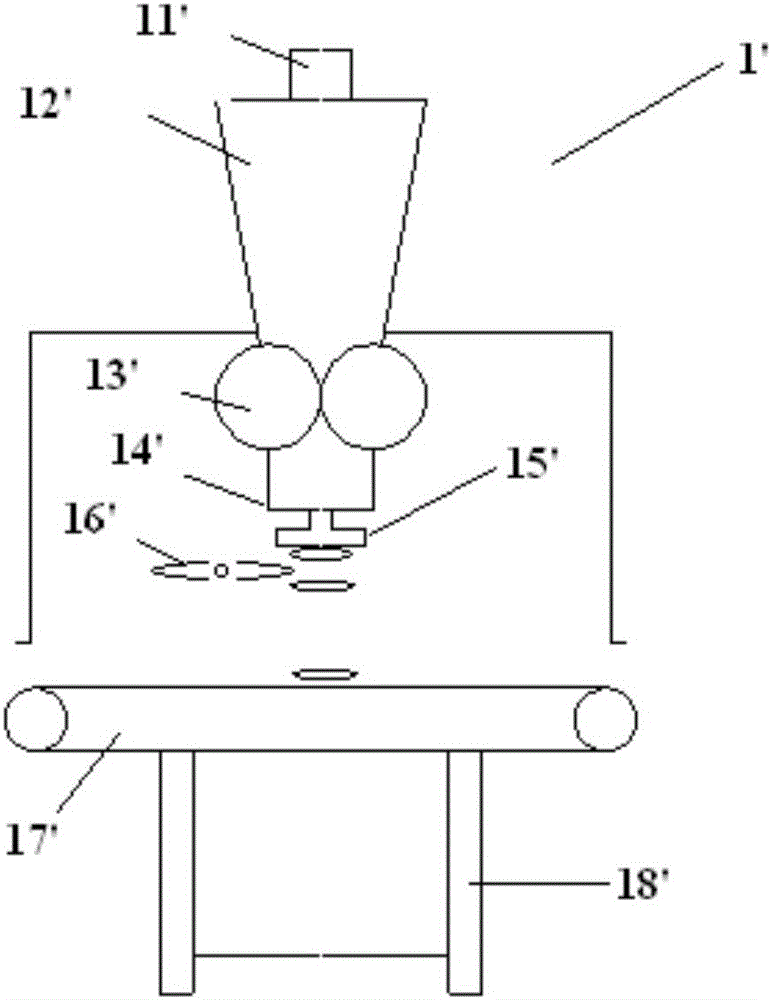

[0025] The biscuit forming station is provided with two kinds of forming devices, one is a molding device 1, and the other is an extruding forming device 1'. In actual production, one of the two can be selected to manufacture corresponding types of biscuits.

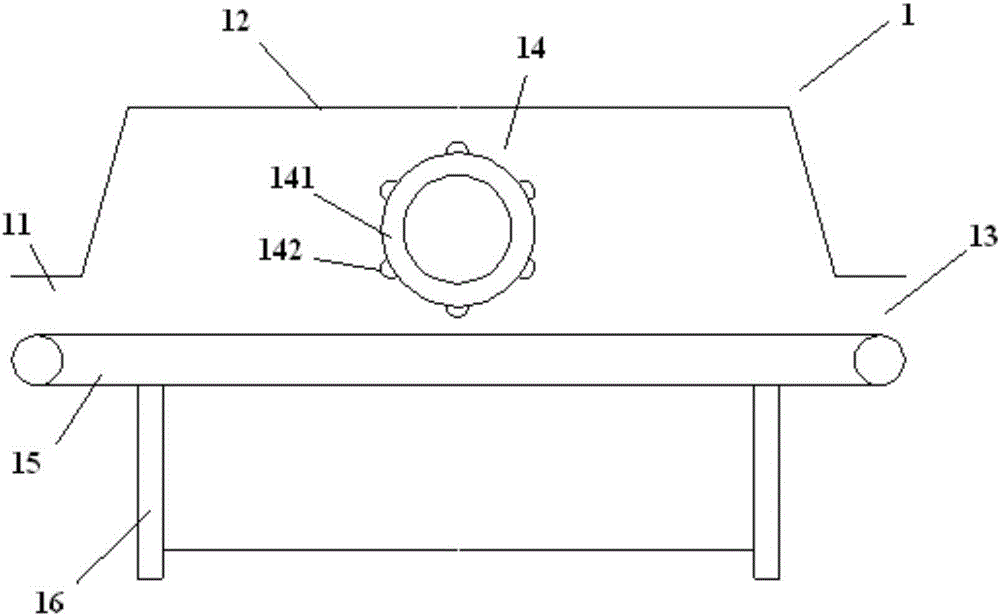

[0026] Such as figure 2 As shown, the molding device 1 includes a continuous dough input port 11, a molding device housing 12, a cake base outlet 13, a molding roller 14, a metal conveyor belt 15, a chassis 16 and a transmission mechanism (not shown) that is arranged on the interior of the chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com