Sheet food processing device

A food processing device and sheet-like technology, applied in the direction of dairy products, cheese substitutes, drying gas arrangement, etc., can solve the problem of insufficient drying of dried tofu and achieve the effect of avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

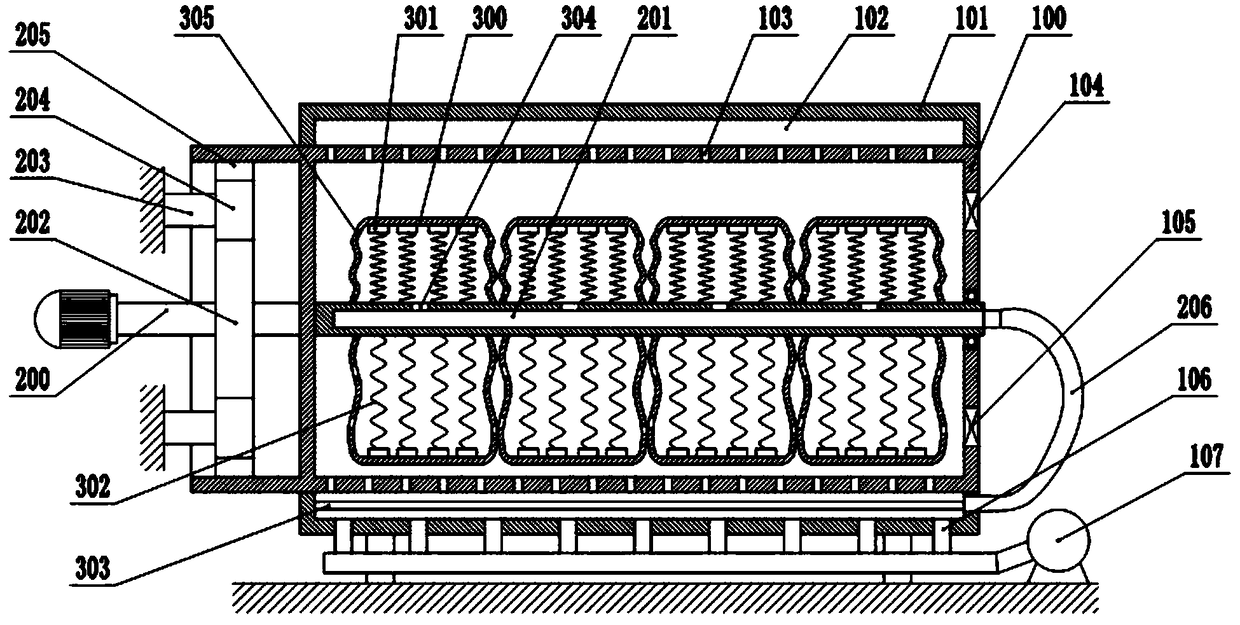

[0030] The reference numerals in the accompanying drawings include: drying cylinder 100, sleeve 101, first cavity 102, hot air hole 103, feed valve 104, pressure relief valve 105, heating hole 106, hot air blower 107, horizontal shaft 200, Second cavity 201, sun gear 202, planet carrier 203, planetary gear 204, ring gear 205, heat pipe 206, air bag 300, first magnet 301, spring 302, second magnet 303, intake check valve 304, exhaust Air hole 305.

[0031] The embodiment is basically as figure 1 Shown:

[0032] A flake food processing device, the device includes a frame, and a drying cylinder 100 is rotatably connected to the frame, wherein the two ends of the drying cylinder 100 are closed and the central axis is set horizontally, and the outer periphery of the drying cylinder 100 is rotationally sealed and fixed on the frame. The sleeve 101, the first cavity 102 is formed between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com