Postirradiation fuel rod vacuum bubble method leak detection box and leak detection system and leak detection method thereof

A technology of vacuum bubbles and fuel rods, applied in the direction of reducing greenhouse gases, climate sustainability, nuclear reactor monitoring, etc., can solve the problems of high sealing requirements, low detection sensitivity, difficult installation, etc., to achieve easy installation and structural strength. Guarantee and achieve the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

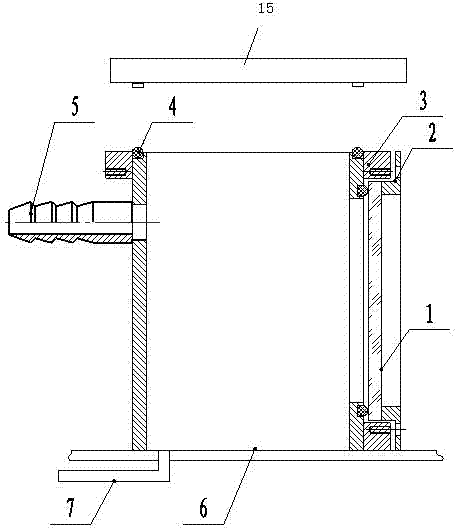

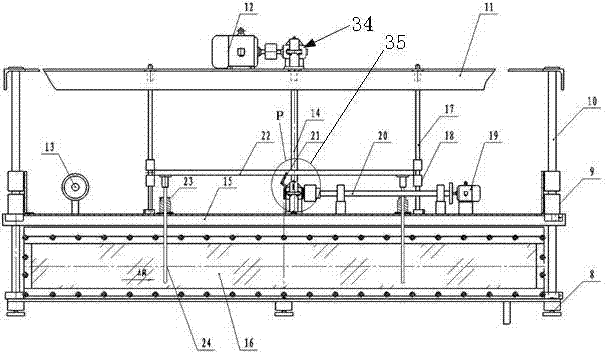

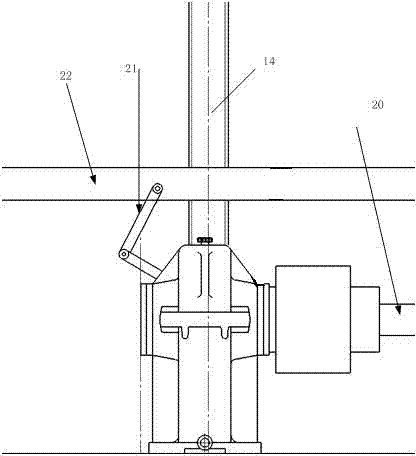

[0062] Such as Figure 1 to Figure 4 shown.

[0063] After irradiation, the fuel rod vacuum bubble method leak detection box includes a leak detection box body 16 with an upper end opening, and a groove is arranged on the upper opening end surface of the leak detection box body, and a sealing strip 4 is arranged in the groove. A cover plate 15 is also arranged above the box body, and the cover plate 15 is provided with a protruding block facing the leak detection box body, and the protruding block is inserted into the groove to seal the upper open end of the leak detection box body.

[0064] Since the present invention adopts the leak detection process on the irradiated fuel rods, the cooperating installation of the above-mentioned groove and the protruding block of the cover plate 15 is realized by the cover plate guide rod 10 and the supporting linear bearing slider 9 automatic positioning At the same time, a protruding block is set under the cover plate to ensure the posi...

Embodiment 2

[0077] Based on the leak detection method of the fuel rod vacuum bubble method leak detection system after irradiation, the leak detection method includes the following steps:

[0078] A. Fuel rod baking step: Use a baking device to bake the surface of the fuel rod; That may exist If the fuel rod is damaged, the fuel rod will be under the water surface for a long time, and the inside will enter the liquid due to the pressure. The vacuum bubble method leak detection adopted in the present invention needs to form a hollow inside the damaged fuel rod with a certain amount of gas, and the bubbles at the damaged part can only be observed when the vacuum bubble method is used for leak detection. Therefore, the present invention uses a roasting device to roast the fuel rods, and discharges the liquid that may exist inside the fuel rods, while other methods for discharging liquids cannot Due to the narrow environment and limited release conditions , not very suitable for the target...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com