Vacuum oven and drying method of power lithium ion cell pole piece

A lithium-ion battery, vacuum oven technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of low heating efficiency, combustion, and long drying process time, and improve drying uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

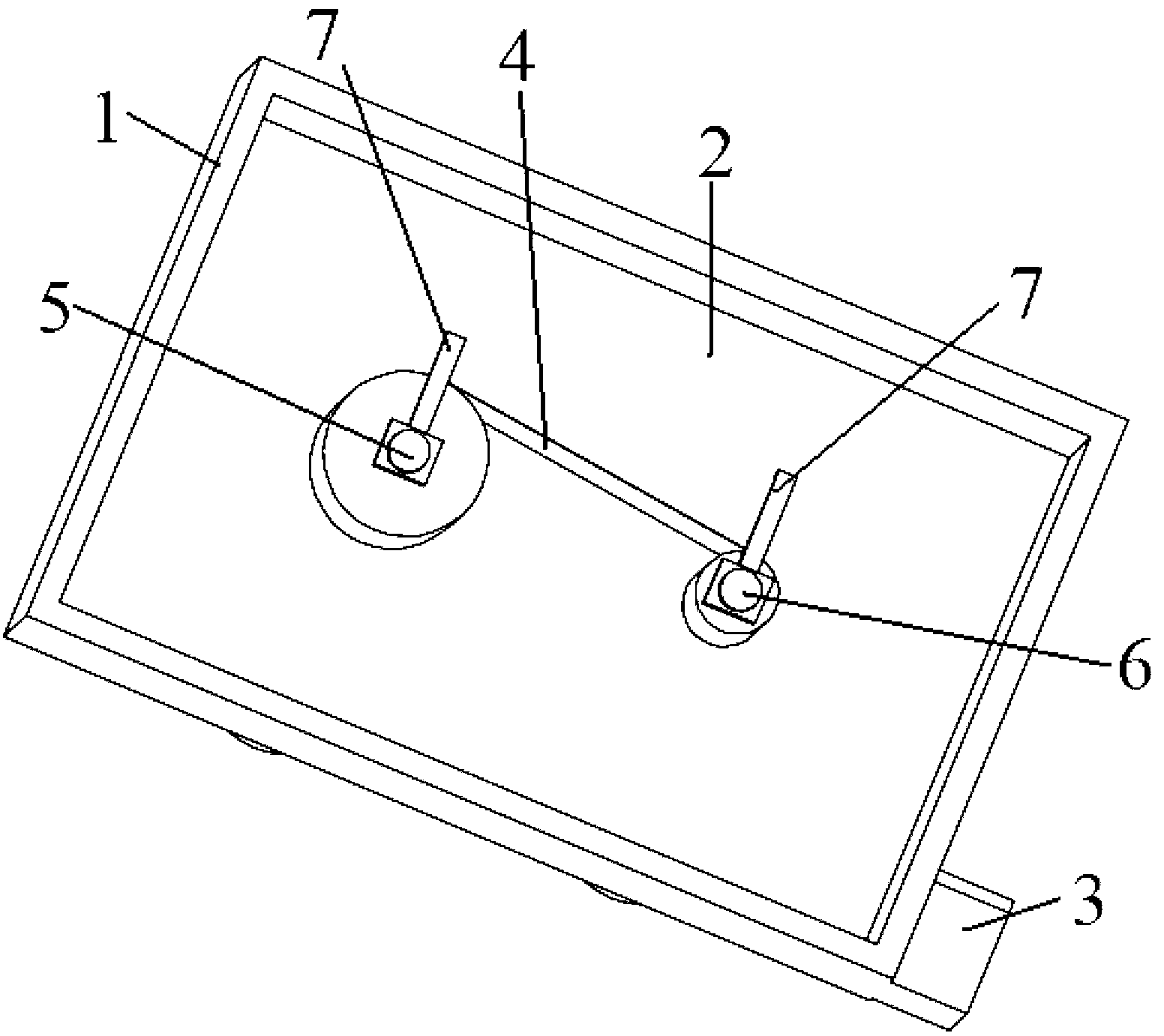

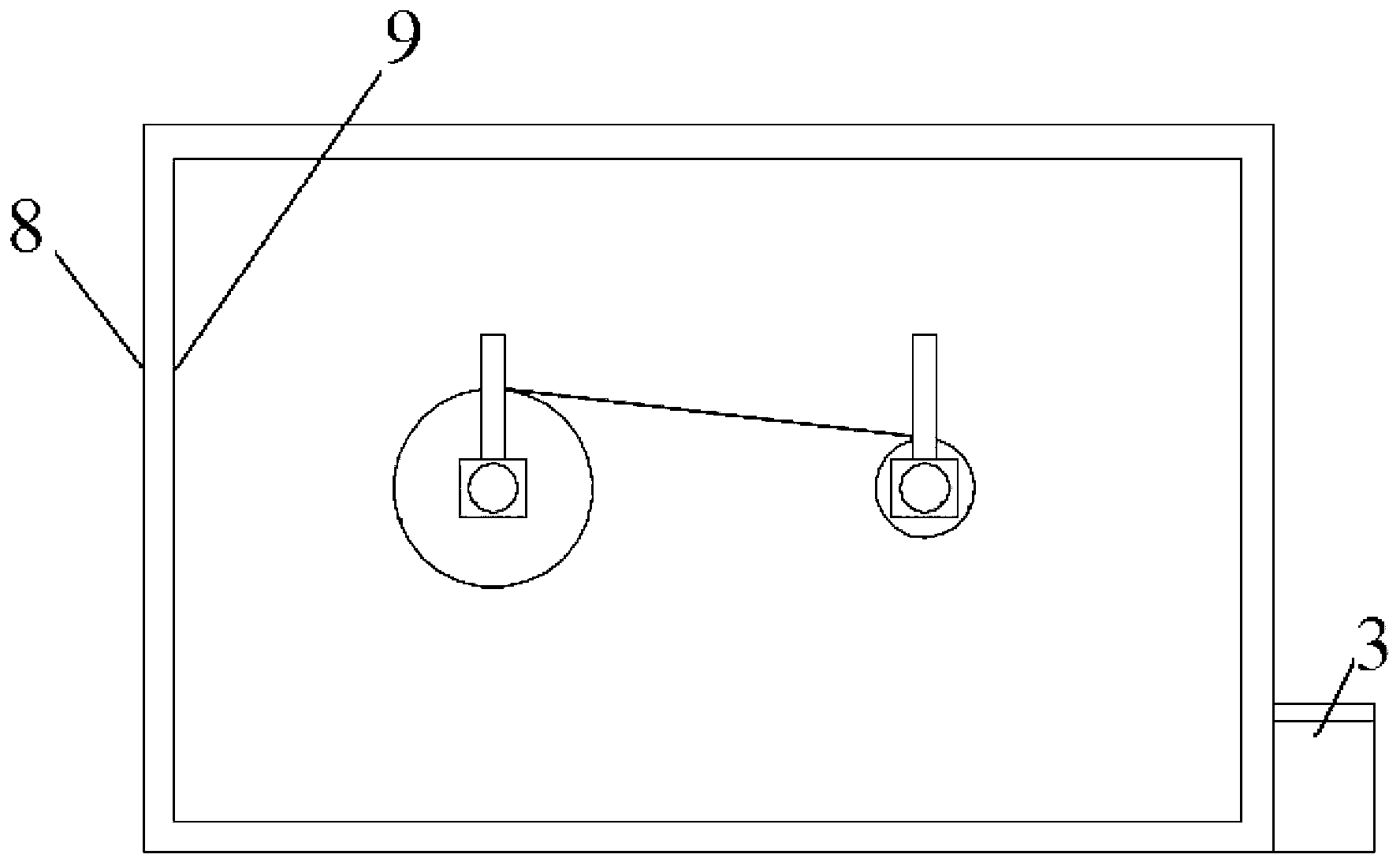

[0021] Such as figure 1 , figure 2 and image 3 Shown is a vacuum oven for a pole piece of a power lithium ion battery according to the present invention, which includes a casing 1, a heating device 3 and a vacuuming device, the vacuuming device is the same as that of the prior art, the casing 1 is rectangular, and the casing Inside the body 1 is a rectangular drying chamber 2, which is used to accommodate and dry battery pole pieces. The vacuum oven of the present invention is provided with two parallel rotating shafts that can rotate in the drying chamber 2, which are respectively the first rotating shaft 5 and the second rotating shaft 6, and the pole piece coil material 4 is wound on the two rotating shafts at both ends. On the top, the two rotating shafts can rotate in both directions to drive the pole piece coil 4 to wind back and forth. During the winding process of the pole piece coil 4, the heating device 3 bakes the pole piece coil 4 at the same time, and the pole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com