Electric cooker remote control method

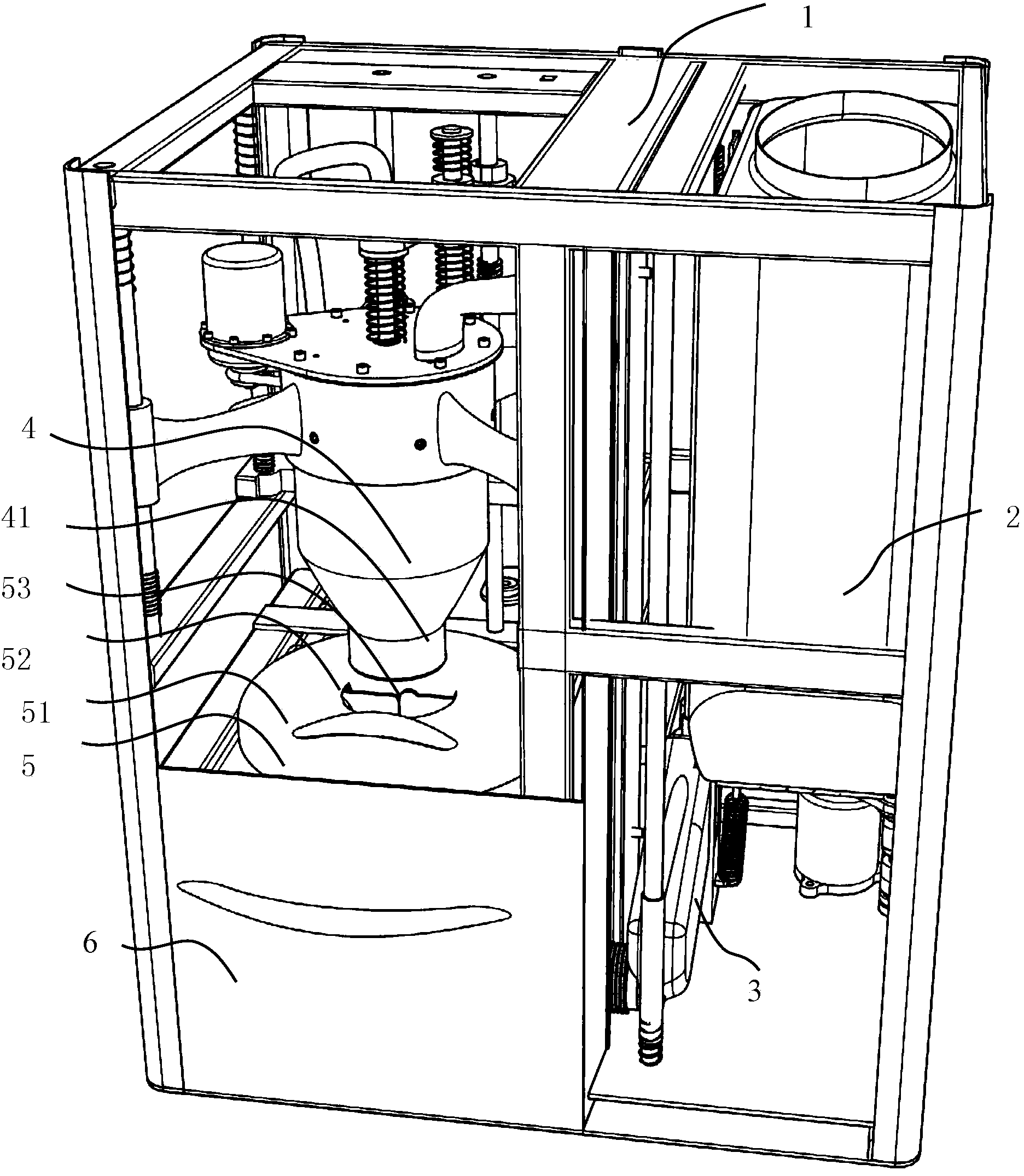

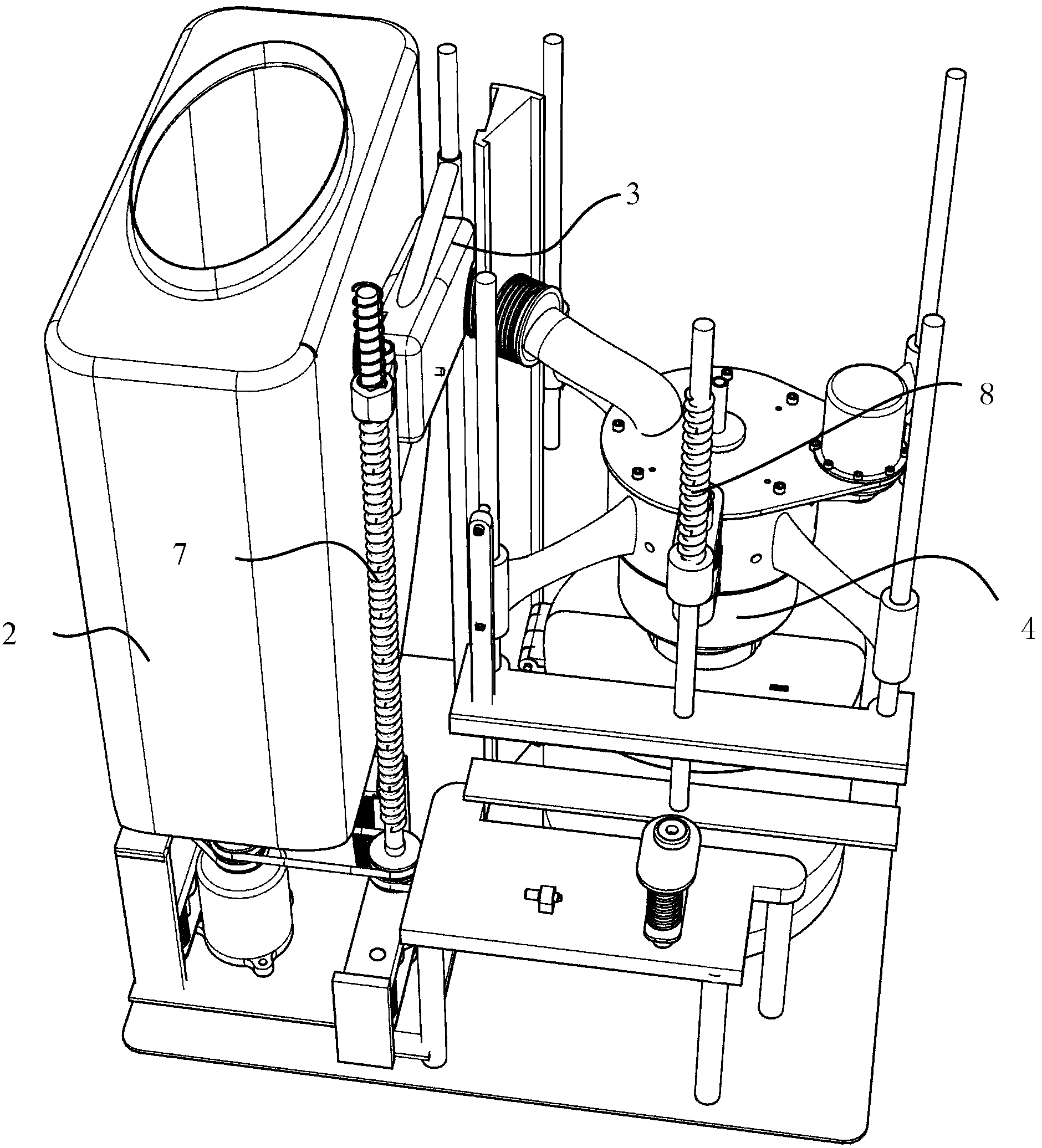

A remote control, rice cooker technology, used in electrical program control, program control in sequence/logic controllers, cooking utensils, etc., can solve power failure or insufficient rice, bacterial growth, unable to automatically add rice, wash rice, add water and other problems to achieve the effect of saving control time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

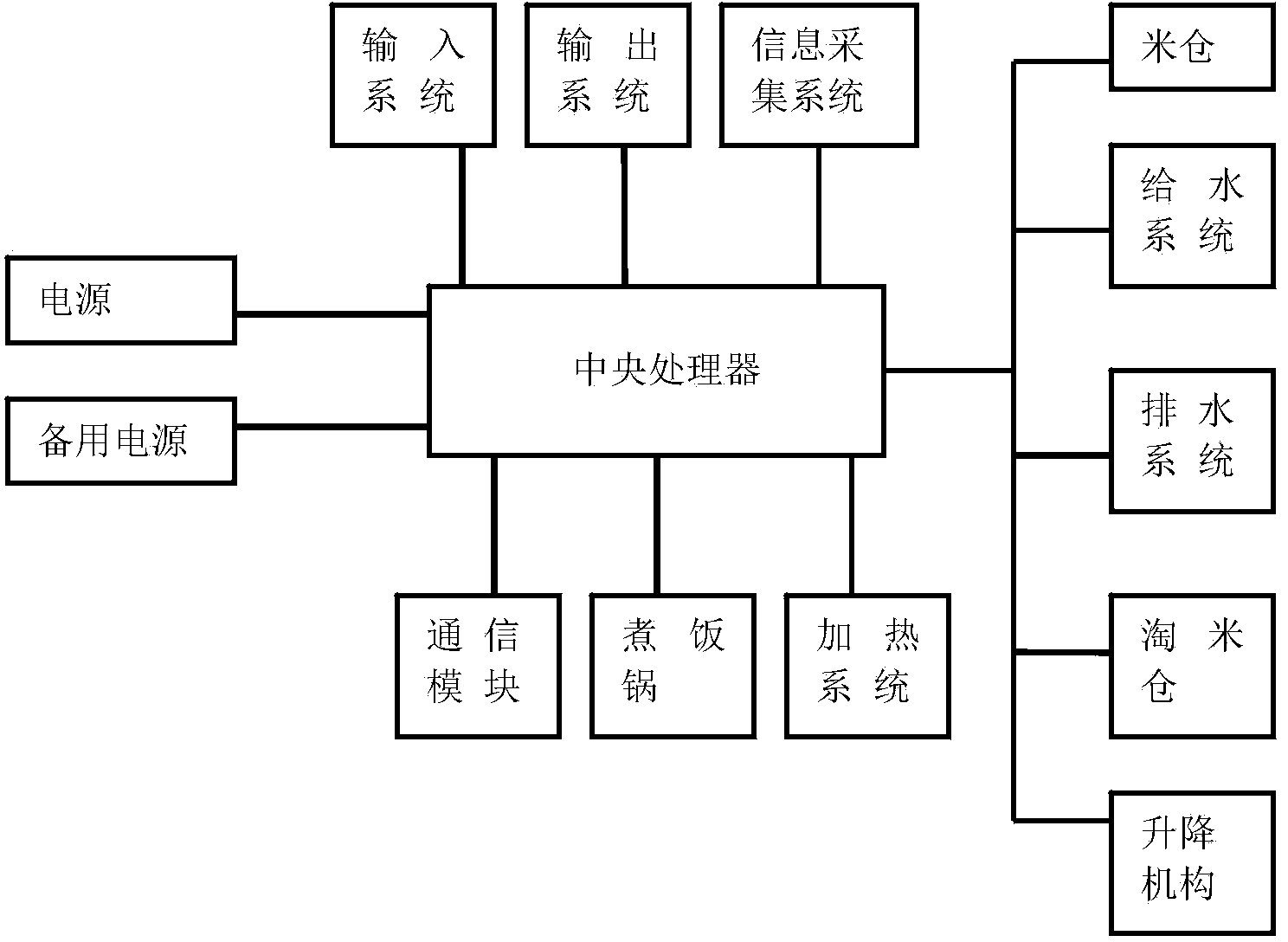

[0069] Embodiment 1: as Figure 4 As shown, the steps for the central processing unit to specifically control the hardware of the rice cooker through the program:

[0070] The first step is to check the power supply source, judge whether the power supply comes from the power supply or the backup power supply according to the current detection of the power supply circuit, and send the detection signal to the central processing unit for processing, and judge the power supply source. If the power supply is from the power supply, the CPU controls the execution of the second step. If the power supply comes from a backup power source, the central processing unit sends a power outage message or the power plug is not plugged in to the user’s mobile terminal or computer through the communication module, or displays a power outage or power plug not plugged in prompt on the LCD screen of the rice cooker. The operating system remains in standby. Check the source of power supply to deter...

Embodiment 2

[0088] Embodiment 2: as Figure 5 As shown, the steps for the central processing unit to specifically control the hardware of the rice cooker through the program:

[0089] The first step is to check the power supply source, judge whether the power supply comes from the power supply or the backup power supply according to the current detection of the power supply circuit, and send the detection signal to the central processing unit for processing, and judge the power supply source. If the power supply is from the power supply, the CPU controls the execution of the second step. If the power supply comes from a backup power source, the central processing unit sends a power outage message or the power plug is not plugged in to the user’s mobile terminal or computer through the communication module, or displays a power outage or power plug not plugged in prompt on the LCD screen of the rice cooker. The operating system remains in standby. Checking the source of the power supply c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com