Preparation method of activated carbon with high pore volume

A technology of activated carbon and high porosity, applied in the field of preparation of high pore volume activated carbon, can solve the problem of difficulty in preparing high pore volume activated carbon and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

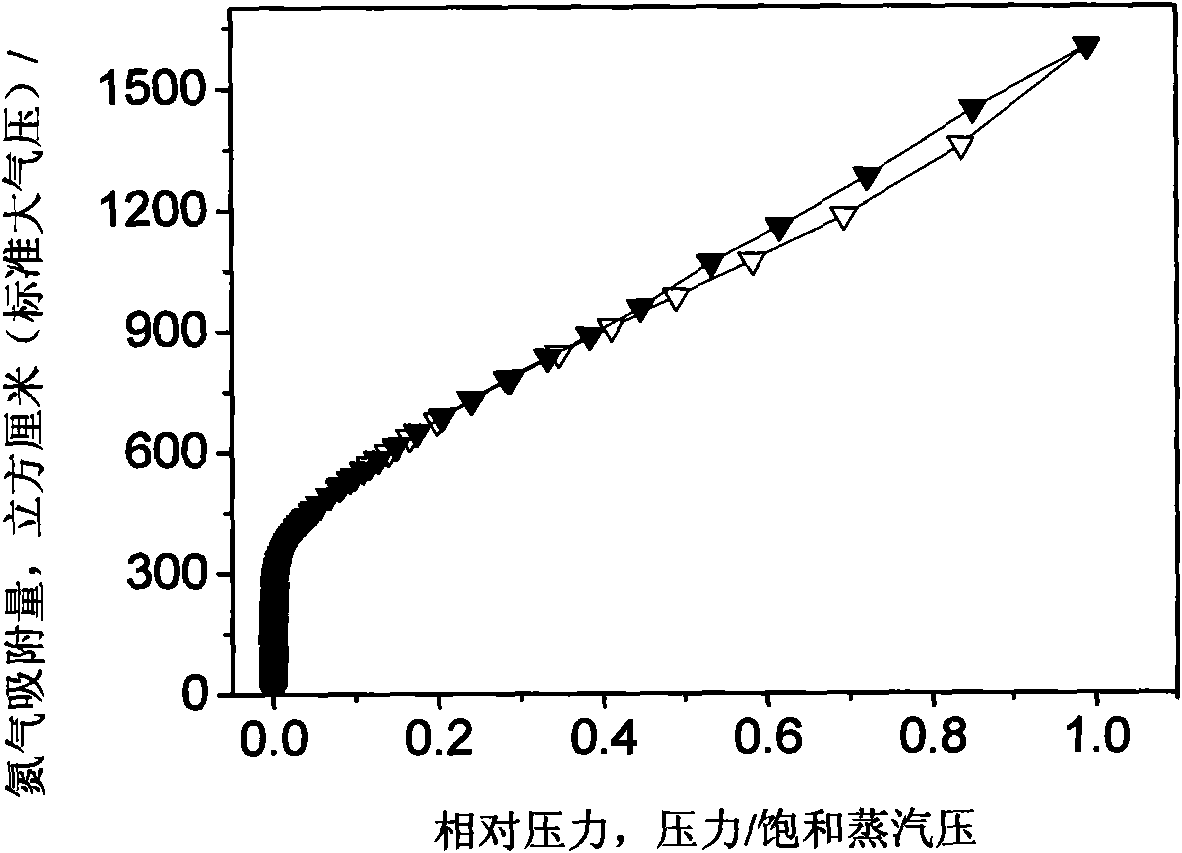

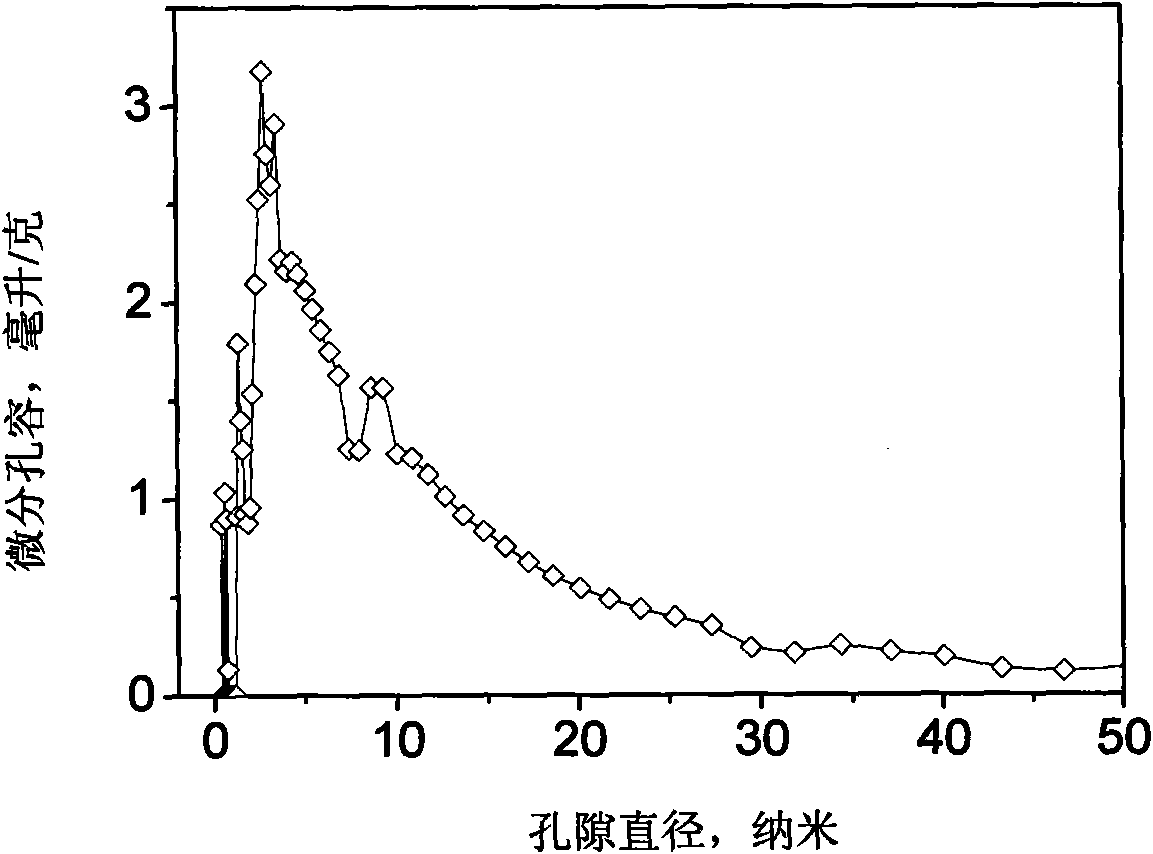

Embodiment 1

[0025] After mixing 10mL of ammonium persulfate solution with a concentration of 2% (w / w) and 80mL of 50% (w / w) phosphoric acid solution, and then mixing it with 20.0g of Chinese fir sawdust, the weight of Chinese fir sawdust, phosphoric acid and ammonium persulfate The ratio is 1:2.4:0.01, soaked at 70°C for 10h, the obtained mixed material is heated to 500°C at a heating rate of 5°C / min, activated for 1h, then taken out, washed with water until the pH of the filtrate reaches 6-7, Dry at 120°C to obtain the product activated carbon. Its specific surface area is 1970m 2 / g, the total pore volume is 1.872cm 3 / g, the mesopore volume is 1.354cm 3 / g, accounting for 72.5% of the total pore volume. Its caramel decolorization rate is 130%.

Embodiment 2

[0027] Concentration is after the hydrogen peroxide solution 10mL of 3% (w / w) is mixed with the phosphoric acid solution of 100mL 50% (w / w), after mixing with the Chinese fir sawdust of 20.0g again, the weight ratio of Chinese fir sawdust, phosphoric acid and hydrogen peroxide is 1: 3.0:0.015, impregnated at 80°C for 10h, the obtained mixed material was heated to 500°C at a heating rate of 3°C / min, activated for 1h, then taken out, washed with water until the pH of the filtrate reached 6-7, and dried at 100°C to obtain Product Activated Carbon. Its specific surface area is 2430m 2 / g, the total pore volume is 2.382cm 3 / g, the mesopore volume is 1.798cm 3 / g, accounting for 75.5% of the total pore volume. Its caramel decolorization rate is 145%.

Embodiment 3

[0029] After mixing 10mL of ammonium persulfate solution with a concentration of 5% (w / w) and 100mL of 40% (w / w) phosphoric acid solution, after mixing with 20.0g of crushed coconut shell raw materials, coconut shell, phosphoric acid and persulfate The weight ratio of ammonium sulfate is 1:2.7:0.025, soaked at 85°C for 12h, the obtained mixed material is heated up to 550°C at a heating rate of 5°C / min, activated for 2h, then taken out, washed with water until the filtrate reaches pH 6-7, dry at 120°C to obtain the product activated carbon. Its specific surface area is 2210m 2 / g, the total pore volume is 1.934cm 3 / g, the mesopore volume is 1.297cm 3 / g, accounting for 67.1% of the total pore volume. Its caramel decolorization rate is 140%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com