Three-product coal slurry flotation machine and system

A coal slime flotation and flotation machine technology, applied in flotation, solid separation and other directions, can solve the problems of reduced economic benefits, inability to adjust at the same time, waste of resources, etc., and achieves low investment cost, easy implementation and high recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention can provide multiple types of three-product coal slime flotation machines. In the embodiments, only shallow groove mechanical agitation flotation machines are used for further description:

[0033] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

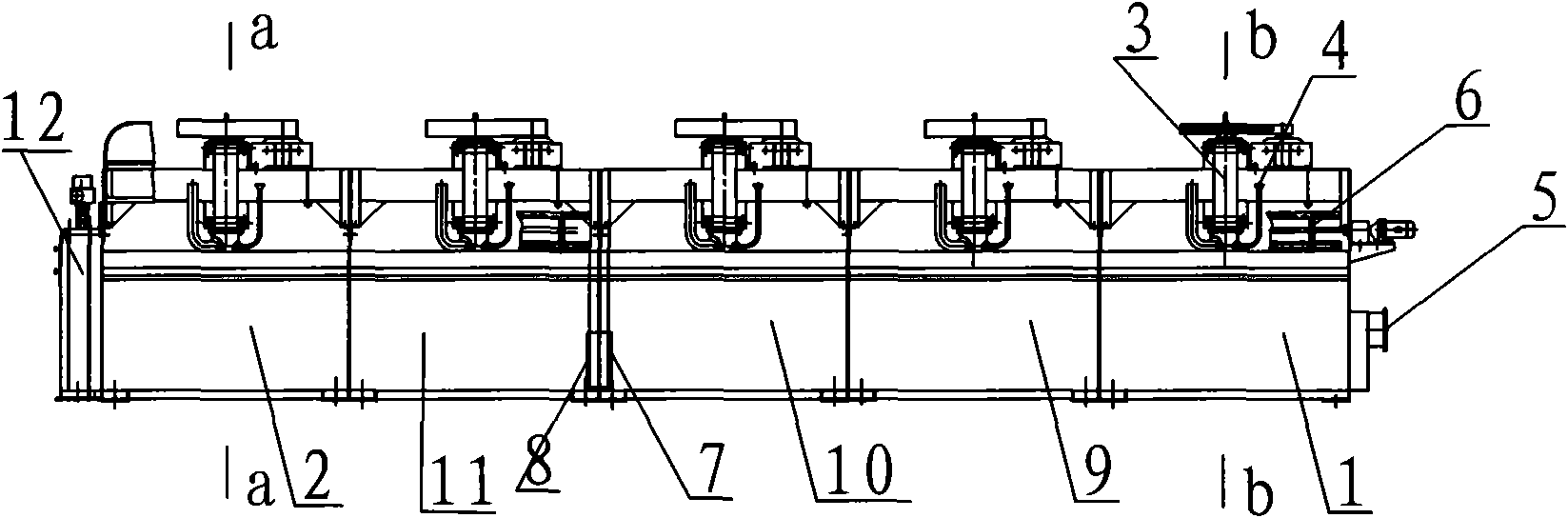

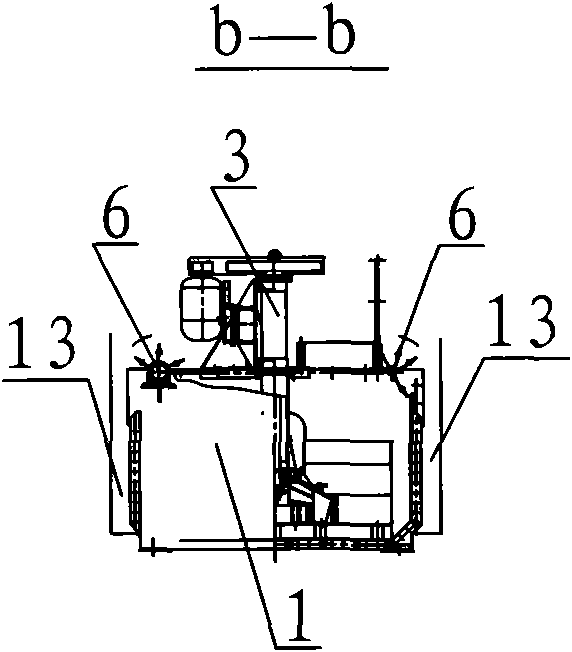

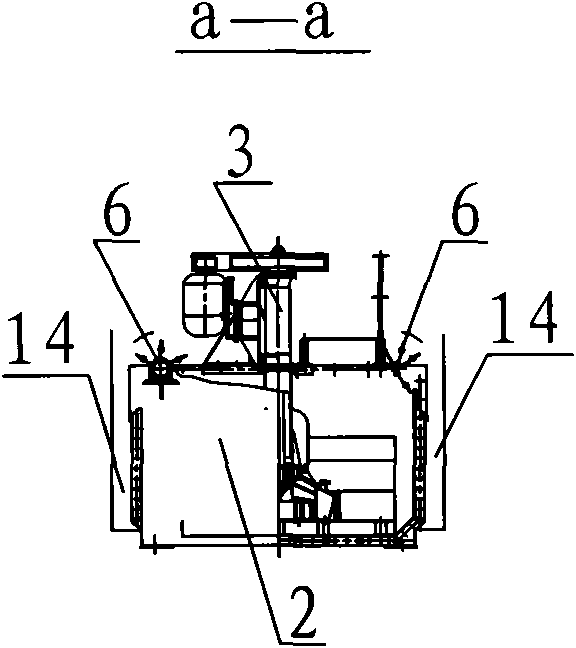

[0034] exist figure 1 , figure 2 and image 3 Among them, a kind of three-product five-chamber shallow groove mechanically agitated coal slime flotation machine of the present invention includes a first-stage refining chamber composed of the first flotation chamber 1, the second flotation chamber 9, and the third flotation chamber 10. device, and a secondary selection device consisting of the fourth flotation chamber 11 and the fifth flotation chamber 2. Wherein the first flotation chamber 1, the second flotation chamber 9, the third flotation chamber 10, the fourth flotation chamber 11, and the fifth flotation chamber 2 are identical u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com