A kind of separation method of alcohol fermentation mash

A technology of alcohol fermentation mash and separation method, which is applied in the field of separation of alcohol fermentation mash, which can solve the problems of low separation efficiency, difficulty in solid-liquid separation, deepening color of DDGS feed, etc., and achieve low ash content and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

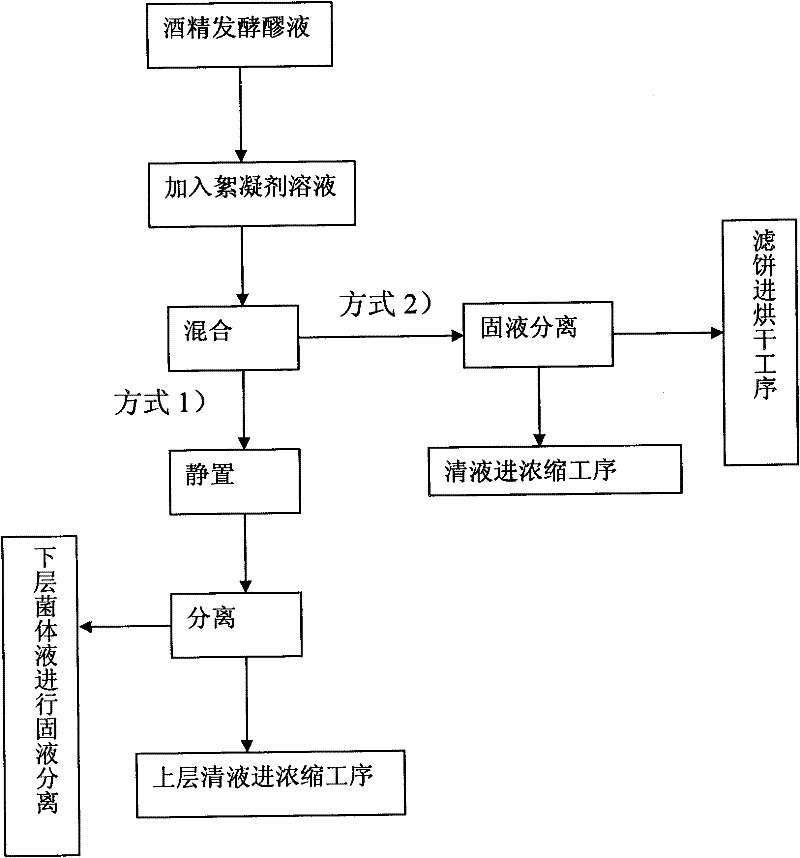

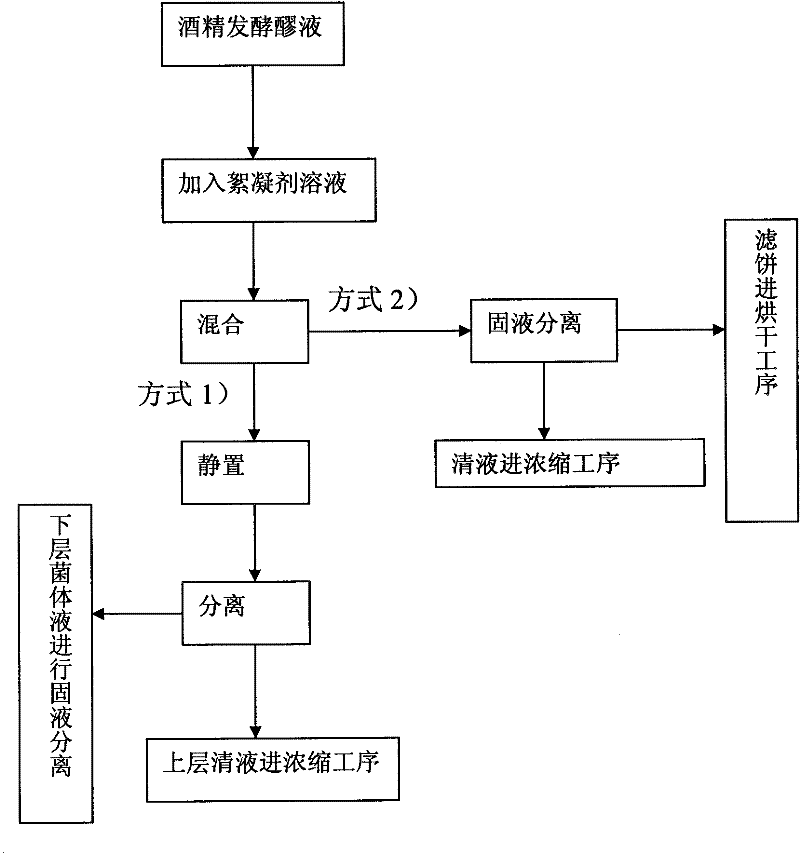

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is used to illustrate the separation method of the alcohol fermentation mash provided by the present invention.

[0045] (1) 500ml alcohol fermentation mash [thalline concentration is 5.32% (m / v)] is placed in reaction tank.

[0046] (2) dissolving an anionic polyacrylamide flocculant with a molecular weight of 15 million in water to obtain a solution with a concentration of 0.2% by mass to volume; and adding the aqueous flocculant solution to the alcoholic fermentation mash at 70°C, Based on per cubic meter of fermentation broth, the amount of the flocculant aqueous solution (12.5ml) was such that the amount of flocculant was 50ppm, and stirred and mixed for 10 minutes.

[0047] (3) The mixed liquor that step (2) obtains is inserted in the plate-and-frame filter and filtered, and the filtration speed of the clear liquid is 15s / 100ml, until the fermented mash enters, the turbidity of the clear liquid obtained is 534NTU.

[0048] (4) the filter cake obta...

Embodiment 2

[0050] This embodiment is used to illustrate the separation method of the alcohol fermentation mash provided by the present invention.

[0051] (1) 500ml alcohol fermentation mash [thalline concentration is 5.32% (m / v)] is placed in reaction tank.

[0052] (2) dissolving an anionic polyacrylamide flocculant with a molecular weight of 15 million in water to obtain a solution with a concentration of 0.2% by mass to volume; and adding the aqueous flocculant solution to the alcoholic fermentation mash at 70°C, On the basis of per cubic meter of fermentation broth, the amount of the flocculant aqueous solution (25ml) is such that the amount of flocculant is 100ppm, and stirred and mixed for 10 minutes.

[0053] (3) The mixed liquor that step (2) obtains is inserted in the plate-and-frame filter and filtered, and the filtration speed of the clear liquid is 12s / 100ml, and until the fermented mash enters, the turbidity of the clear liquid obtained is 520NTU.

[0054] (4) the filter c...

Embodiment 3

[0056] This embodiment is used to illustrate the separation method of the alcohol fermentation mash provided by the present invention.

[0057] The alcohol fermentation mash was separated according to the method of Example 1, the difference was that the amount of the flocculant aqueous solution (5ml) made the amount of the flocculant to be 20ppm on the basis of per cubic meter of fermented liquid. The filtration rate of the clear liquid is 29s / 100ml, and the turbidity of the obtained clear liquid is 660NTU. The filter cake was dried at 90° C. to obtain an ash content of 2.87% (m / m) and a protein content of 27.29% (m / m) in the feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com