Application of calcium silicate as retention aiding intensifier in papermaking

A technology of calcium silicate and thickening agent, which is applied in the field of papermaking to achieve the effects of saving plant fiber consumption, high bulk thickness and increasing paper ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1 active calcium silicate

[0027] 1), pre-desilication, the mixed solution composed of high-alumina fly ash and 20% sodium hydroxide solution (the mass ratio of sodium hydroxide and high-alumina fly ash is 0.5:1) is heated to 110°C. , introduce it into a pressure-resistant container for desiliconization reaction for 2h, and then carry out liquid-solid separation to obtain liquid-phase desiliconization liquid and solid-phase fly ash filter cake. High aluminum fly ash; alumina mass content in high aluminum fly ash is higher than 40%;

[0028] 2), the preparation of active calcium silicate, comprises the following steps: a, in step 1), in the desiliconization liquid, add lime milk to react, the available calcium oxide concentration in the lime milk is 150g / L, and in the available calcium oxide and the filtrate, SiO 2 The molar ratio is 1, the reaction temperature is 80 ° C, and the reaction time is 60 min, and the filter is filtered to obta...

Embodiment 2

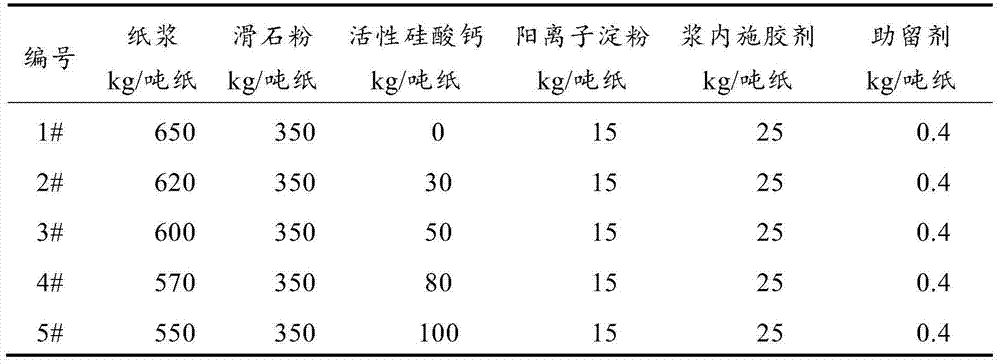

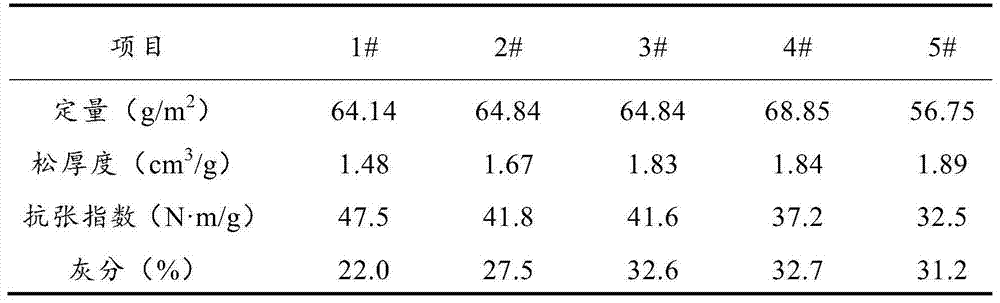

[0029] Example 2 Calcium silicate is used for paper making

[0030] 1. Experimental materials

[0031] Activated calcium silicate prepared in Example 1; commercial softwood pulp and broadleaf pulp; filler is talcum powder.

[0032] 2. Experimental method

[0033] (1) The active calcium silicate is fully mixed with water according to the solid content of 3%, and dispersed; the linear speed of the dispersing blade of the disperser is 6.5m / s, and the dispersion time is 30min; the dispersed calcium silicate dispersion is sieved through a 100-mesh sieve Sieve treatment, the slurry is ready for use;

[0034] (2) Soft-leaved pulp: the broad-leaved pulp is prepared according to the mass ratio of 3:7, wherein the beating degree of the soft-leaved pulp is 40°SR, and the beating degree of the broad-leaved pulp is 35°SR;

[0035] (3) adding papermaking filler talc and the slurry prepared in step (1) into the slurry prepared in step (2) simultaneously;

[0036] (4) Add other papermakin...

Embodiment 3

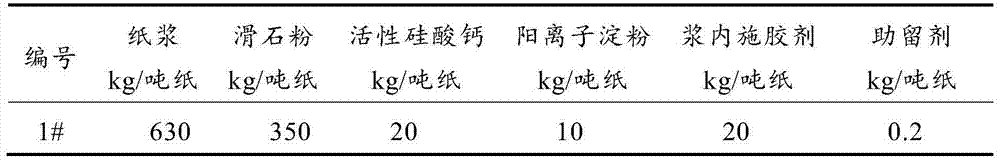

[0047] Example 3 Calcium silicate is used for paper making

[0048] 1. Experimental materials

[0049] Activated calcium silicate prepared in Example 1; commercial softwood pulp and broadleaf pulp; filler is talcum powder.

[0050] 2. Experimental method

[0051] (1) The active calcium silicate is fully mixed with water according to the solid content of 2%, and dispersed; the linear speed of the dispersing blade of the disperser is 5m / s, and the dispersion time is 25min; the dispersed calcium silicate dispersion is sieved through a 100-mesh sieve processing, the slurry is ready for use;

[0052] (2) Soft-leaved pulp: the broad-leaved pulp is prepared according to the mass ratio of 3:7, wherein the beating degree of the soft-leaved pulp is 40°SR, and the beating degree of the broad-leaved pulp is 35°SR;

[0053] (3) first adding the papermaking filler talc powder to the slurry prepared in step (2), and then adding the slurry prepared in step (1) to the slurry;

[0054] (4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com