Sugar clarification technique method for intensifying stoving neutralization reaction

A process method, the technology of sulfur fumigation, applied in the field of improved sugar clarification process, can solve the problems of uneven particle size, large residual amount, high sulfur content of white sugar, etc., and achieve uniform precipitated particles, firm precipitated particles, and good adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

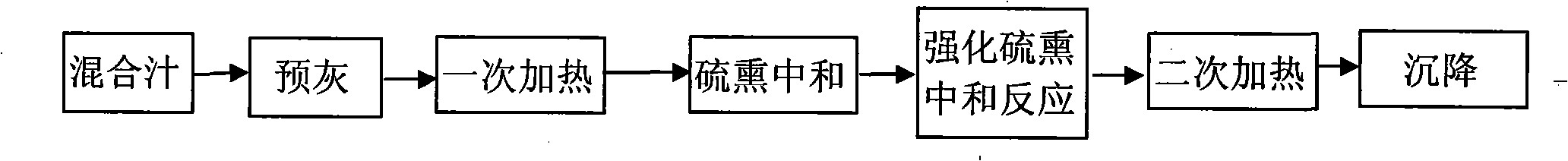

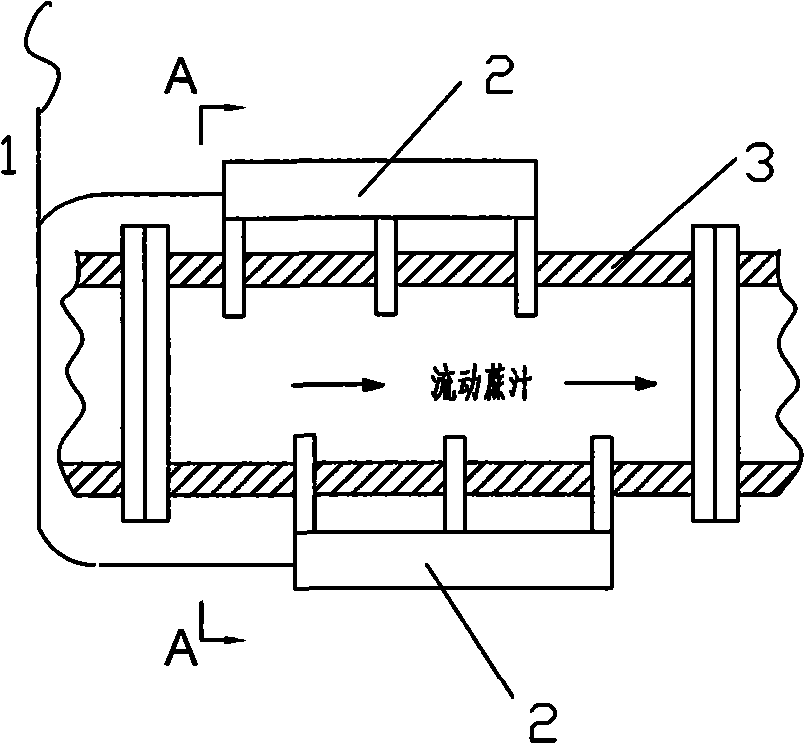

[0035] A sugar clarification process method for strengthening sulfur fumigation neutralization reaction, adopting sulfurous acid clarification process, including: pre-ashing, primary heating, sulfur fumigation neutralization, enhanced sulfur fumigation neutralization reaction, secondary heating and sedimentation process (see figure 1 ), the process of strengthening the sulfur fumigation neutralization reaction is to pass the sulfur fumigation neutralized sugarcane juice through an ultrasonic processor, apply ultrasonic field energy to the flowing sugarcane juice, and carry out ultrasonic intensification treatment to the sulfur fumigation neutralization reaction sugarcane juice , the intensity of ultrasound is 0.8W / cm 2 , the time of ultrasonic strengthening treatment is 20s, and the ultrasonic processor adopted in the present embodiment is a tubular ultrasonic processor, which includes a pipeline 3, and ultrasonic transducers 2 placed on both sides of the outer wall of the pipe...

Embodiment 2

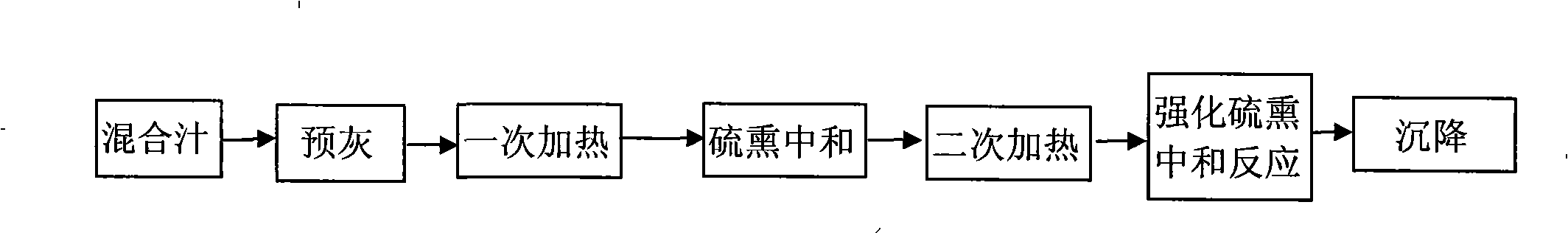

[0037] A sugar clarification process method for strengthening sulfur fumigation neutralization reaction, adopting sulfurous acid clarification process, including: pre-ashing, primary heating, sulfur fumigation neutralization, secondary heating, strengthening sulfur fumigation neutralization reaction and sedimentation process (see figure 2 ), the technological process of its pre-ashing, primary heating, sulfur fuming neutralization, secondary heating and settling process is the same as the conventional sugar clarification process using sulfurous acid clarification, and the described intensified sulfur fuming neutralization reaction process is to After the sulfur fumigation neutralization reaction, after the secondary heating process, the cane juice before entering the sedimentation process is subjected to ultrasonic strengthening treatment, and the intensity of the ultrasonic wave is 0.8W / cm 2 , the time of ultrasonic strengthening treatment is 40s, and the ultrasonic processor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com