Surface glue reinforcing agent and preparation method thereof

A technology of strengthening agent and surface glue, applied in the field of surface glue strengthening agent and its preparation, can solve the problems of insufficient paper surface strength, increase of cooking equipment, loss of hair and powder, etc., so as to improve the effect, reduce the production cost, and increase the ash content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

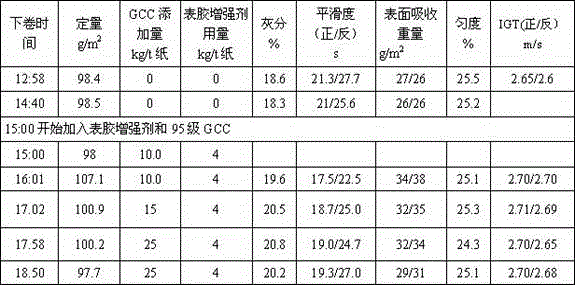

Examples

Embodiment 1

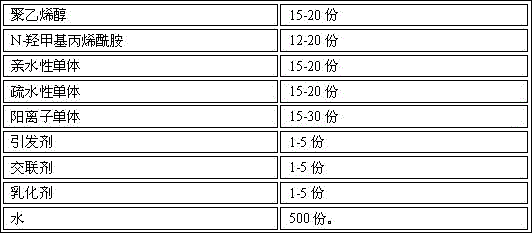

[0032] 15 parts polyvinyl alcohol

[0033] 15 parts of N-methylolacrylamide

[0034] 18 parts of hydrophilic monomer

[0035] Hydrophobic monomer 18 parts

[0036] Cationic monomer 25 parts

[0037] Initiator 3 parts

[0038] 3 parts of cross-linking agent

[0039] 3 parts emulsifier

[0040] 500 parts of water;

[0041] The preparation method specifically comprises the following steps:

[0042] a. Mix solid polyvinyl alcohol with water, stir at room temperature for 0.5h, raise the temperature to 95°C, stir and dissolve, keep warm until the polyvinyl alcohol is completely dissolved, and obtain polyvinyl alcohol solution A (solid content is controlled at 10%);

[0043] B, initiator is mixed with 8% aqueous solution;

[0044] c. Mix the emulsifier, water, and hydrophobic monomer, stir at 40°C, and raise the temperature to 80°C to obtain pre-emulsion B;

[0045] d. Add water, N-methylolacrylamide, and hydrophilic monomer into the reaction kettle, stir and mix evenly, rai...

Embodiment 2

[0049] 18 parts polyvinyl alcohol

[0050] 16 parts of N-methylolacrylamide

[0051] 15 parts of hydrophilic monomer

[0052] Hydrophobic monomer 20 parts

[0053] Cationic monomer 18 parts

[0054] Initiator 4 parts

[0055] 4 parts of cross-linking agent

[0056] Emulsifier 5 parts

[0057] 500 parts of water;

[0058] The preparation method specifically comprises the following steps:

[0059] a. Mix solid polyvinyl alcohol with water, stir at room temperature for 0.5h, raise the temperature to 96°C, stir and dissolve, keep warm until the polyvinyl alcohol is completely dissolved, and obtain polyvinyl alcohol solution A (solid content is controlled at 9%);

[0060] B, initiator is mixed with 7% aqueous solution;

[0061] c. Mix the emulsifier, water, and hydrophobic monomer, stir at 45°C, and raise the temperature to 80°C to obtain pre-emulsion B;

[0062] d. Add water, N-methylolacrylamide, and hydrophilic monomer into the reaction kettle, stir and mix evenly, rais...

Embodiment 3

[0066] 20 parts polyvinyl alcohol

[0067] 12 parts of N-methylolacrylamide

[0068] 18 parts of hydrophilic monomer

[0069] Hydrophobic monomer 15 parts

[0070] Cationic monomer 22 parts

[0071] Initiator 5 parts

[0072] Cross-linking agent 5 parts

[0073] 3 parts emulsifier

[0074] 500 parts of water;

[0075] The preparation method specifically comprises the following steps:

[0076] a. Mix solid polyvinyl alcohol with water, stir at room temperature for 0.5h, raise the temperature to 94°C, stir and dissolve, keep warm until the polyvinyl alcohol is completely dissolved, and obtain polyvinyl alcohol solution A (solid content is controlled at 11%);

[0077] B, initiator is mixed with 9% aqueous solution;

[0078] c. Mix emulsifier, water, and hydrophobic monomer, stir at 50°C, and heat up to 85°C to obtain pre-emulsion B;

[0079] d. Add water, N-methylolacrylamide, and hydrophilic monomer into the reaction kettle, stir and mix evenly, raise the temperature to 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com