Catalyzing and cracking slurry oil settling agent and preparation method and application thereof

A technology of catalytic cracking oil slurry and settling agent, which is applied in chemical instruments and methods, separation methods, petroleum industry, etc. It can solve the problems of long settling time, difficulty in implementation, increase of settling tank construction site and cost, etc., and achieve high settling speed , reduce ash content, shorten the effect of settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

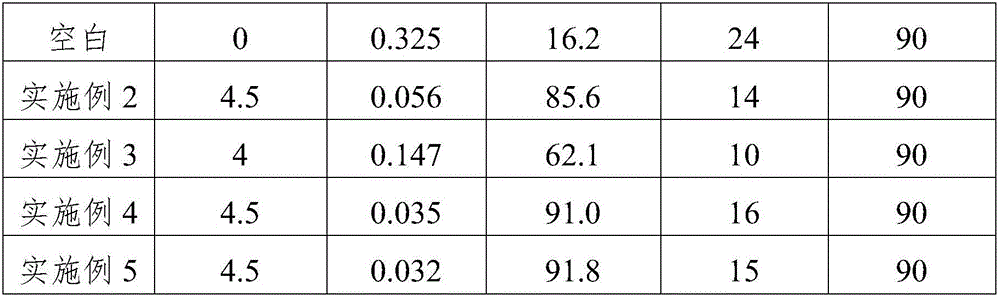

Examples

Embodiment 1

[0017] A sedimentation agent for catalytic cracking oil slurry, which is composed of the following raw materials in mass percentage: polyoxyethylene polyoxypropylene block polymer 11.5%, PPG8000 7.2%, dimethyl diallyl ammonium chloride homopolymer 6.5%, Polyoxyethylene sorbitan laurate 4.5%, balance is aromatic hydrocarbon oil.

[0018] Preparation method: Add polyoxyethylene polyoxypropylene block polymer, PPG8000, dimethyl diallyl ammonium chloride homopolymer, polyoxyethylene sorbitan laurate into aromatic oil, and heat up to 60°C , stir until evenly mixed, that is.

Embodiment 2

[0020] A sedimentation agent for catalytic cracking oil slurry, composed of the following raw materials in mass percentage: polyoxyethylene polyoxypropylene block polymer (molecular weight 8400) 11.2%, PPG8000 7.6%, dimethyl diallyl ammonium chloride homopolymer Compound (molecular weight: 500,000) 6.0%, polyoxyethylene sorbitan laurate 5.4%, S-150 aromatic hydrocarbon solvent 69.8%.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A sedimentation agent for catalytic cracking oil slurry, which is composed of the following raw materials in mass percentage: polyoxyethylene polyoxypropylene block polymer (molecular weight 8400) 10.0%, PPG8000 8.0%, dimethyl diallyl ammonium chloride homopolymer Compound (molecular weight: 500,000) 5.0%, polyoxyethylene sorbitan laurate 6.0%, and the balance is S-150 aromatic hydrocarbon solvent.

[0024] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com