Drying method of tobacco fila in the cigarette processing course

A technology of processing and leaf shreds, which is applied in the direction of tobacco, tobacco preparation, application, etc., can solve the problems of reduced aroma, reduced moisture content, temperature leaf shred filling ability, and failure to achieve better filling ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

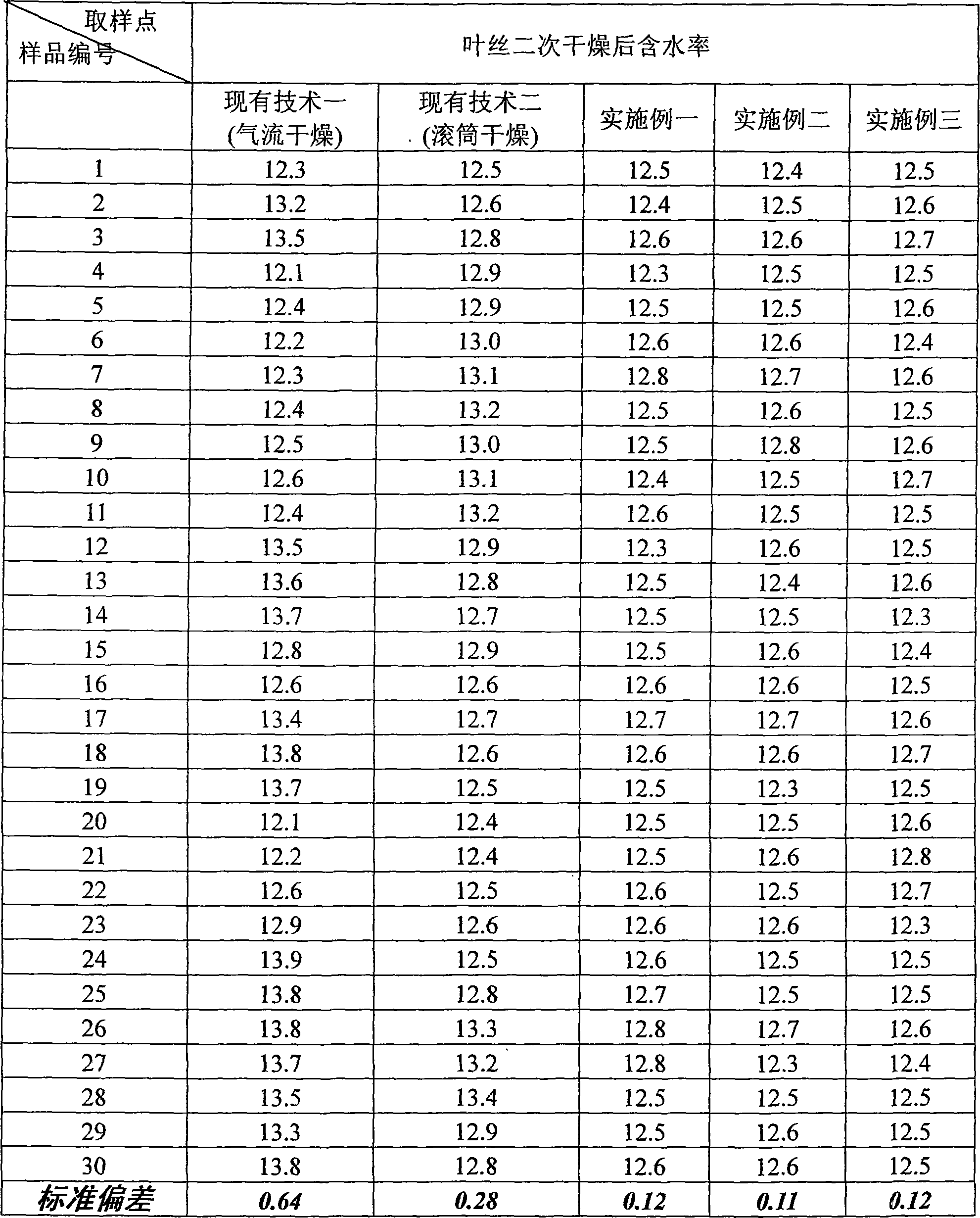

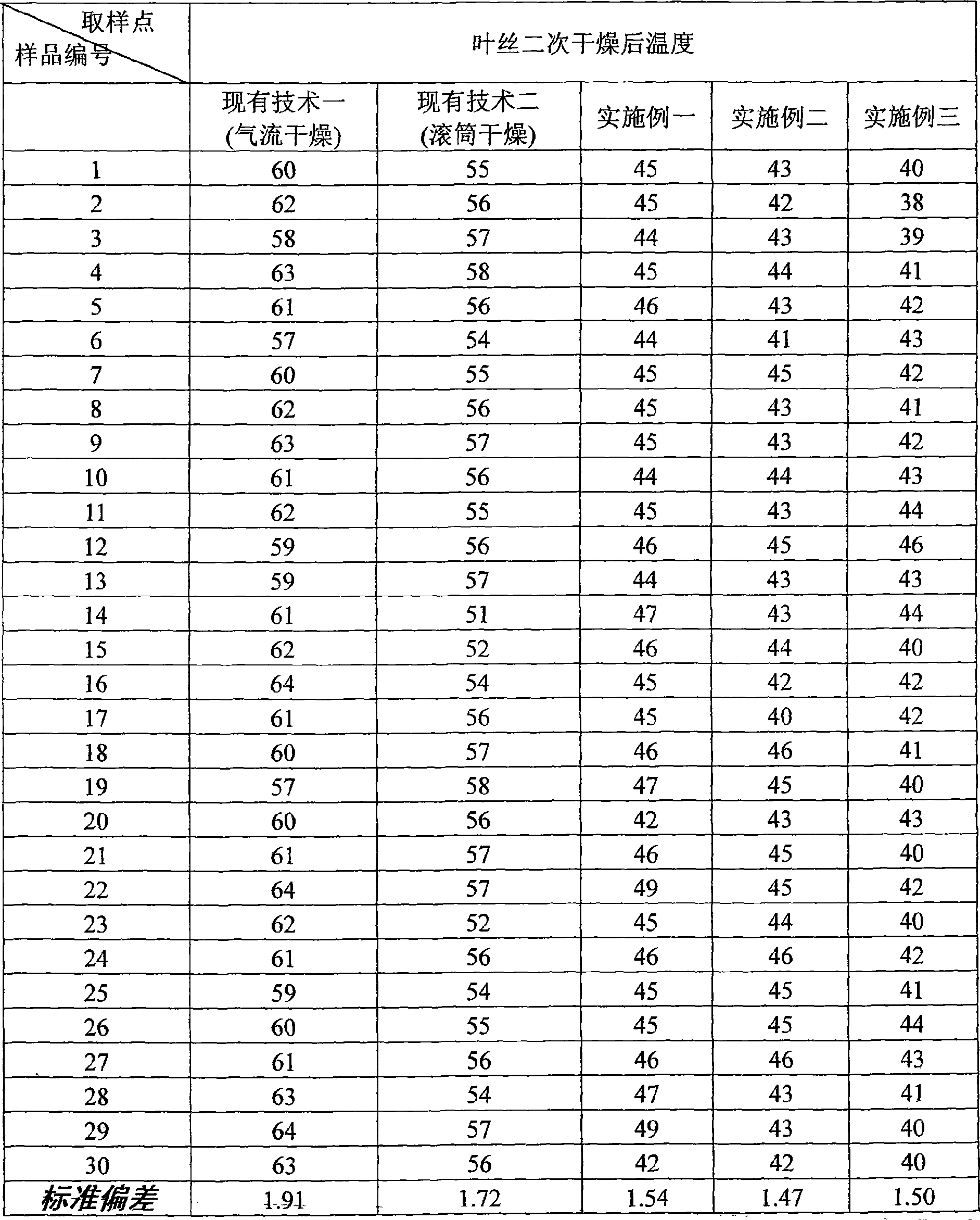

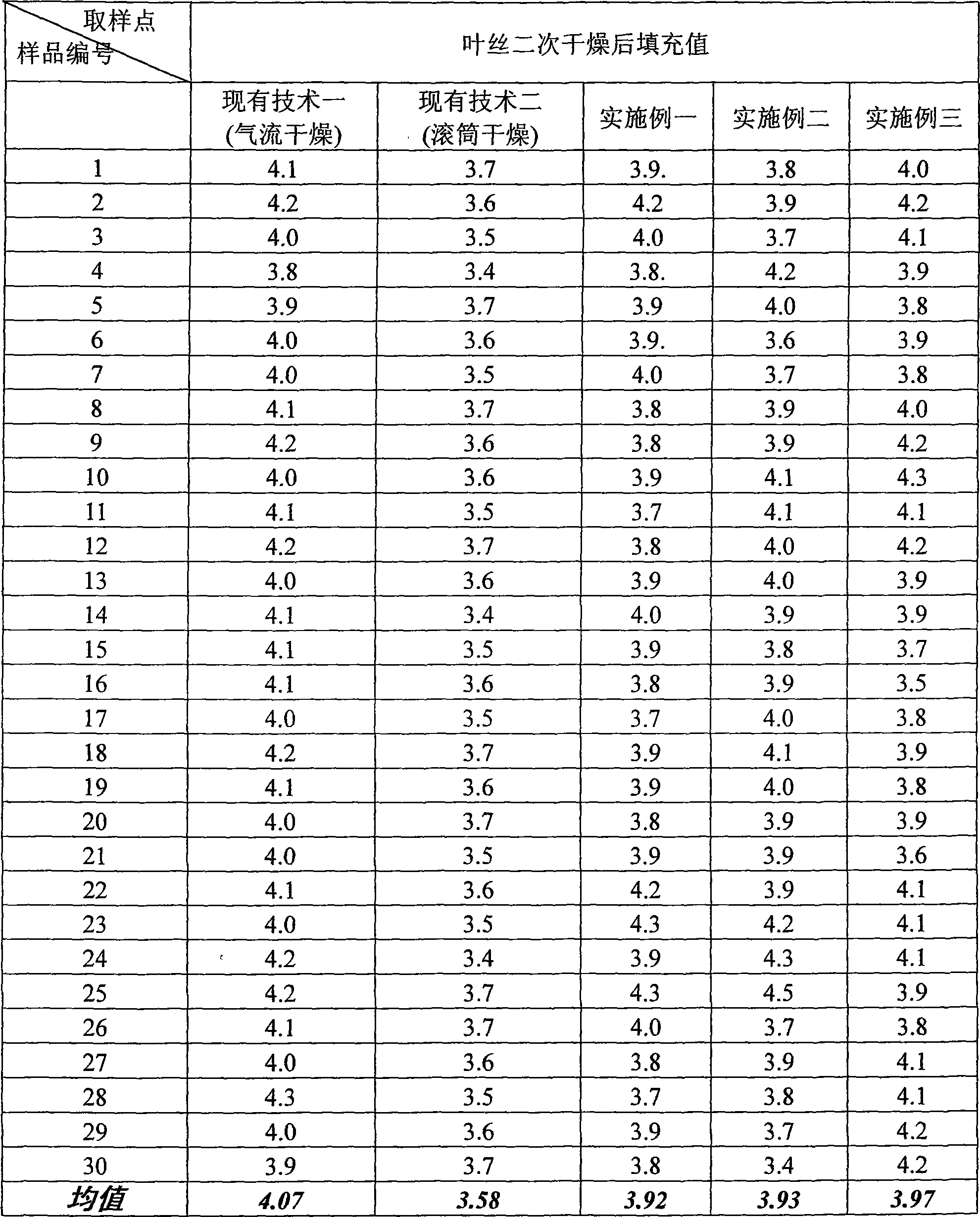

Embodiment 1

[0012] Experiment No. 1 leaf shreds 1800kg, balance the moisture content to 20%, and then import it into the airflow drying equipment by lifting the material belt. The temperature control range of the airflow in the first zone is 80-90℃; The temperature of the back leaf shreds is 40°C, and the moisture content is 16%. The leaf silk with a moisture content of 16% after drying is introduced into the drum drying equipment by lifting the material belt. The temperature of the cylinder wall is set at 80°C. After drying again, the outlet leaf silk temperature is 45.4°C and the moisture content is 12.55%. The water content of cut leaves after treatment in this example is shown in attached table 1, the temperature of cut leaves after treatment is shown in attached table 2, the filling value of shredded leaves after treatment is shown in attached table 3, and the sensory evaluation results of shredded leaves after treatment are shown in Table 2 As shown in Attached Table 4, the chemical...

Embodiment 2

[0014] Experiment No. 2 shredded leaf is 1800kg. After the moisture content is balanced to 20%, it is introduced into the airflow drying equipment by lifting the material belt. The temperature control range of the airflow in the first zone is 85-95℃; The temperature of the back leaf shreds is 42°C, and the moisture content is 15%. The leaf silk with a moisture content of 15% after drying is introduced into the drum drying equipment by lifting the material belt. The temperature of the cylinder wall is set at 75°C. After drying again, the outlet leaf silk temperature is 43.6°C and the moisture content is 12.55%. The water content of cut leaves after treatment in this example is shown in attached table 1, the temperature of cut leaves after treatment is shown in attached table 2, the filling value of shredded leaves after treatment is shown in attached table 3, and the sensory evaluation results of shredded leaves after treatment are shown in Table 2 As shown in Attached Table 4,...

Embodiment 3

[0016] Experiment No. 3 leaf shreds 1800kg, balance the moisture content to 20%, and then import the material belt into the air drying equipment through the lifting material belt. The temperature control range of the air flow in the first area is 90-100°C; The temperature of the back leaf shreds is 45°C, and the moisture content is 14%. The leaf silk with a moisture content of 14% after drying is introduced into the drum drying equipment by lifting the material belt. The temperature of the cylinder wall is set at 70°C. After drying again, the outlet leaf silk temperature is 41.9°C and the moisture content is 12.54%. The water content of cut leaves after treatment in this example is shown in attached table 1, the temperature of cut leaves after treatment is shown in attached table 2, the filling value of shredded leaves after treatment is shown in attached table 3, and the sensory evaluation results of shredded leaves after treatment are shown in Table 2 As shown in Attached Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com