Tobacco peduncle granule production process

A technology of tobacco stems and granules, which is applied in the fields of tobacco, tobacco processing, and application, can solve the problems of increasing the smoking resistance of cigarettes, poor cutting effect, and unstable tobacco stem pressure, so as to reduce woody smell, improve efficiency, and reduce tobacco shreds. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

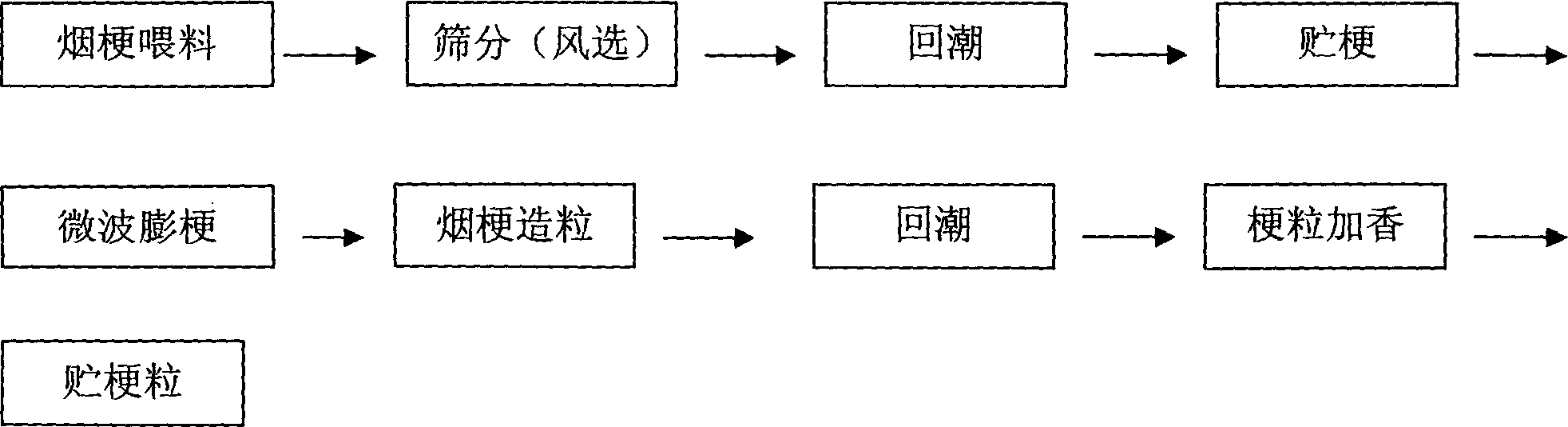

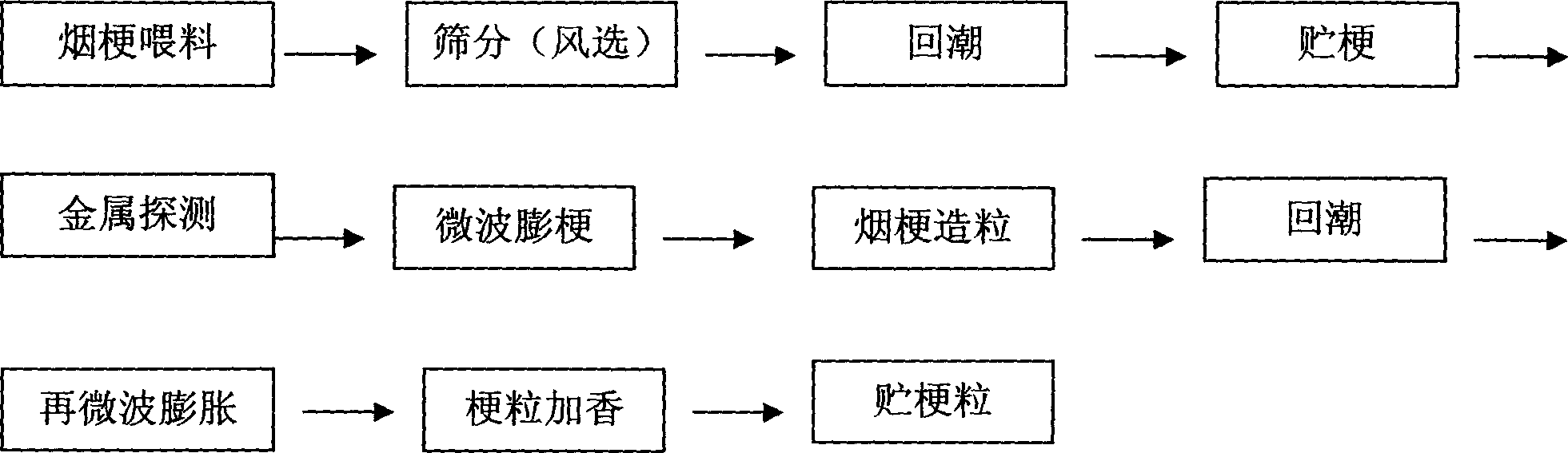

[0018] Such as figure 1 As shown, the present invention feeds the rebaked tobacco stems into the production line as raw materials, first sieves or winnows the minced powder, and then adopts moisture regaining equipment (such as tunnel type tobacco stem moisture regainers, drum type tobacco stem moisture regainers or water washing). stem equipment) to remoisturize the tobacco stems to increase the moisture content of the tobacco stems to 13% to 30%; the rehydrated tobacco stems are stored in the storage cabinet to balance the moisture, and at the same time adjust the production flow before and after. Afterwards, carry out the stalk-expanding granulation process again, and the stalk-expanding granulation process is carried out according to the following steps:

[0019] (1) Microwave stem expansion: use microwave drying equipment to expand and dry the tobacco stems, and control the moisture content of the dried tobacco stems between 4% and 10%;

[0020] (2) Tobacco stem granulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com