Filter tip additional material capable of reducing harmful ingredients as well as preparation method and application thereof

A technology of adding materials and filters, which is applied in the direction of nanotechnology for materials and surface science, applications, e-liquid filter elements, etc., can solve the problems of complex preparation process, high price, single component, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

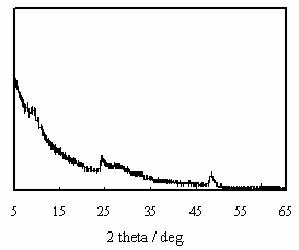

[0019] The preparation method of titanate nanotube is:

[0020] 0.5 ~ 100 grams of cheap TiO 2 After fully mixing the raw material with an alkali solution with a concentration of 10-1000 ml of 5-15 mol / liter, react in a polytetrafluoroethylene container at 373-423K for 1-3 days; the pH value of the generated product is adjusted to 1-7 After fully washing with distilled water, drying at 323-373K under normal pressure for 1-40 hours to prepare the titanate nanotube additive material.

[0021] The pH value of the generated product is adjusted using 0.1-0.5 mol / liter of hydrochloric acid or nitric acid.

[0022] Described drying adopts normal pressure drying.

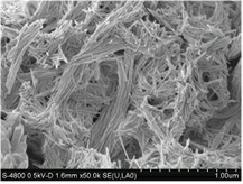

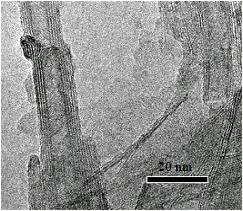

[0023] The prepared titanate nanosheet additive material has a layered structure with a specific surface of 300 m 2 .g -1 Above, the short ones are hundreds of nanometers long, and the long ones can reach the micron level, arranged randomly. The inner diameter of the tube is about 5 nm and the outer diameter is about 1...

Embodiment 1

[0025] Inexpensive TiO at 0.5 g 2 After fully mixing the raw material with a concentration of 10 milliliters of 5 mol / liter alkali solution, react for 1 day at 373K in a polytetrafluoroethylene container; The titanate nanotube additive material was obtained by pressing and drying for 5 hours.

Embodiment 2

[0027] 1 gram of cheap TiO 2 After fully mixing the raw material with a concentration of 20 milliliters of 10 mol / liter alkali solution, react at 393K in a polytetrafluoroethylene container for 1 day; The titanate nanotube additive material was obtained by pressing and drying for 10 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com