Vertical pyrolysis gasifier

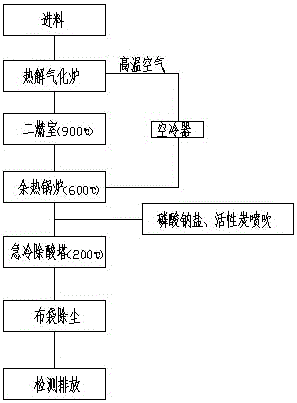

A technology of pyrolysis gasification and pyrolysis gas is applied in the field of vertical pyrolysis gasifier, which can solve the problems of easy pollution of working environment by ash, easy leakage of pyrolysis gasifier, easy blockage of controllable exhaust pipe, etc. To avoid the hidden danger of furnace explosion, improve the gasification efficiency and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

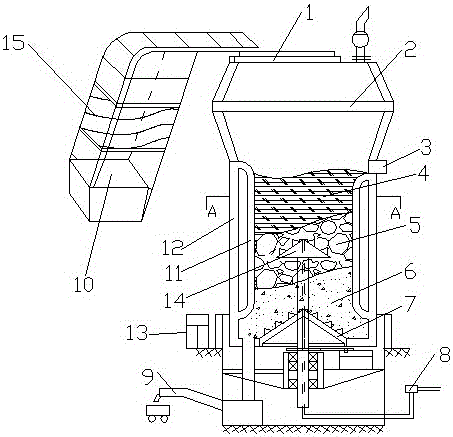

[0031] A vertical pyrolysis gasifier, comprising a feeding mechanism 10 and a slag discharge mechanism 9, the vertical pyrolysis gasifier

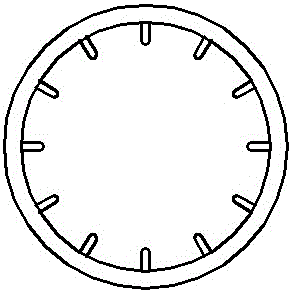

[0032] Several guide pipes 11 are evenly arranged on the inner wall of the furnace to avoid the blockage of the pyrolysis gas flow. The guide pipes 11 communicate with the water jacket 12 to form backflow. The vertical pyrolysis gasifier also It includes a sealing mechanism, a working area and a stirring mechanism. The sealing mechanism includes a first sealing door 1 and a second sealing door 2. The second sealing door 2 is arranged at the V-shaped protrusion at the upper end of the furnace body. The first The airtight door 1 and the second airtight door 2 cannot be opened at the same time; the working area includes a drying area 4, a pyrolysis gasification area 5, and a combustion area 6, and the furnace body at the upper end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com