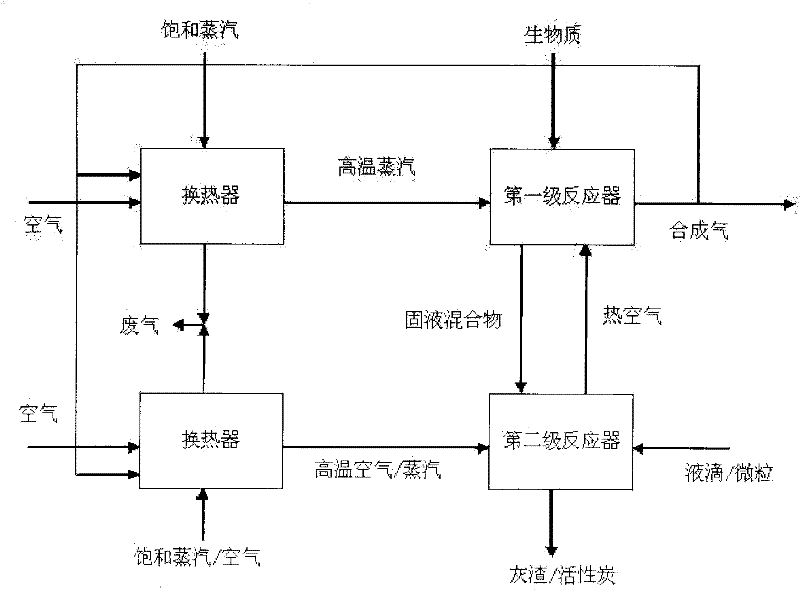

Two-stage high-temperature preheated steam biomass gasification furnace

A high-temperature steam and gasification furnace technology, which is applied in the gasification of granular/powdered fuel, inorganic chemistry, chemical industry, etc., can solve the problems of lack of sufficient research on the high-temperature air gasification process, and the lack of a relatively complete experimental system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

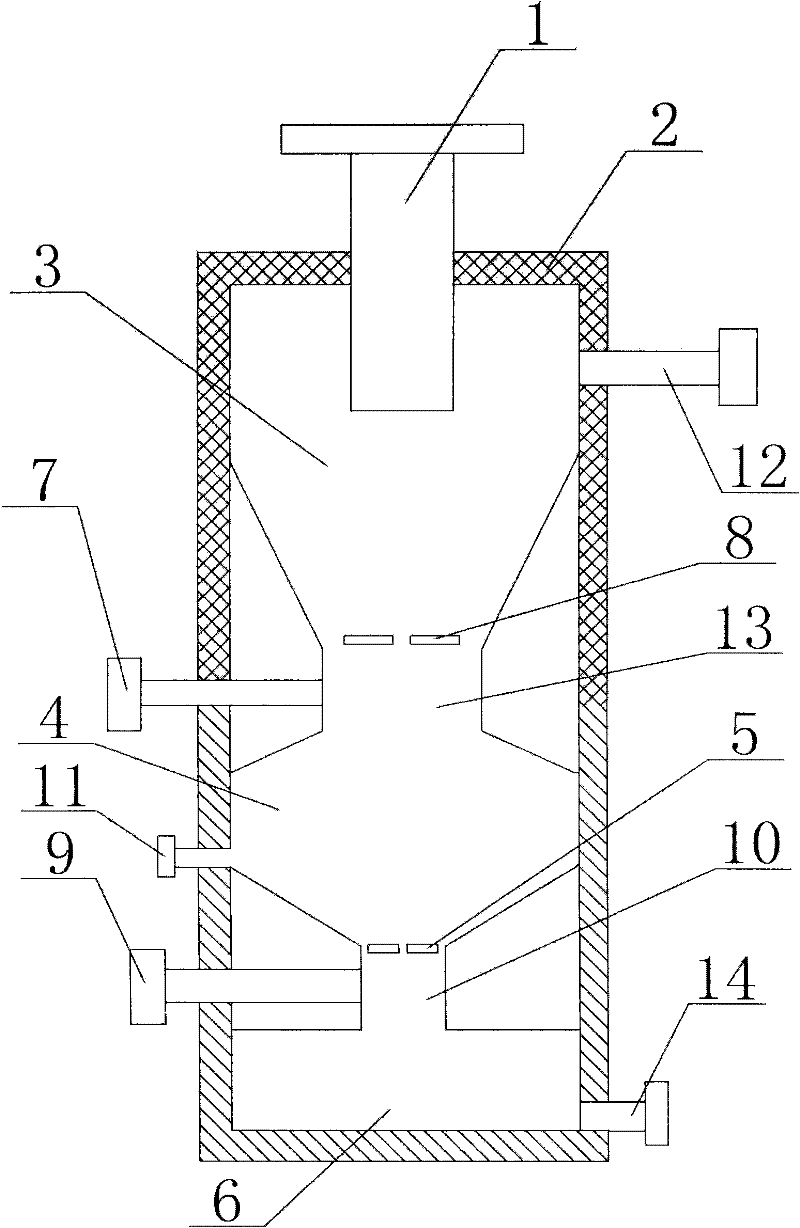

[0068] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0069] In the embodiment, the selected material is solid pellets, so the liquid and particulate feed material injection port 11 in the lower part of the furnace body is in a closed state.

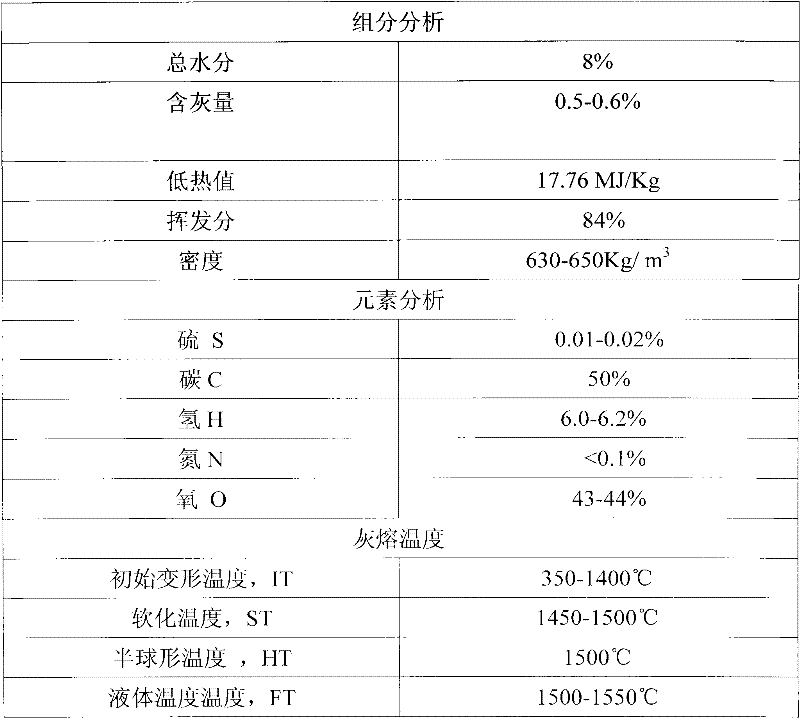

[0070] In the present embodiment, the diameter of the selected solid pellets is about 8mm (the parameters of the wooden pellets are listed in Table 1), and the wooden pellets under the room temperature of 15° C. The mass flow rate is supplied to the first-stage reactor 3 from the solid feed feed end 1, passes through the upper fire grate 8 after passing through the first-stage reactor 3, then enters the second-stage reactor 4, and then passes through the lower fire grate 5 until The molten slag formed in the slag collection chamber 6 is discharged at the slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com