Compound coal gasification system and method of blast furnace slags

A technology of slag gasification and blast furnace slag, which is applied in the direction of granular/powdered fuel gasification, joint combustion mitigation, recycling technology, etc. soil pollution etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

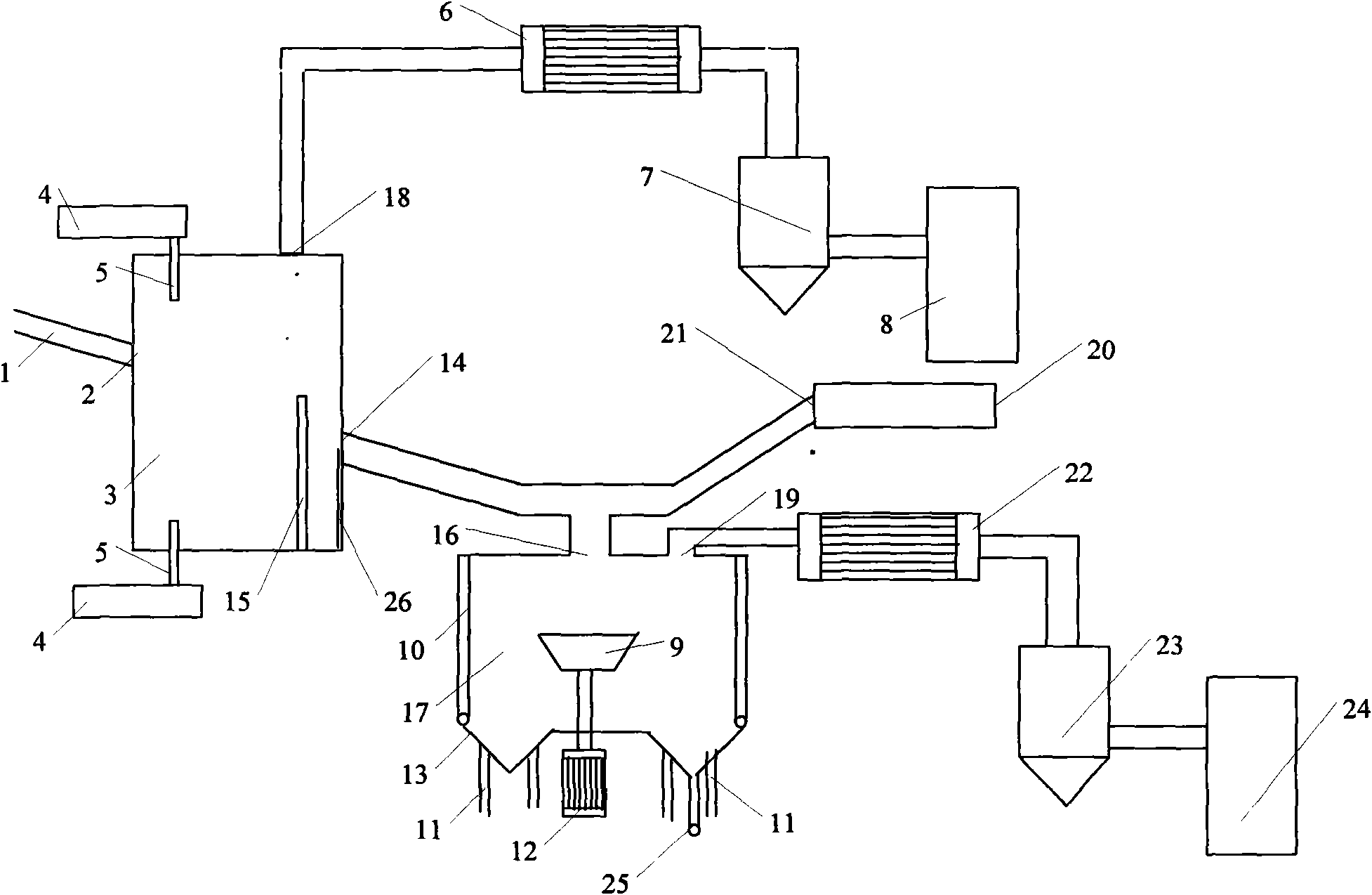

[0068] Blast furnace slag composite coal gasification system such as figure 1 As shown, it includes a slag gasifier 3, a heat exchanger 6, a gas dust collector 7, a gas storage tank 8, a coal feeding device 4, a spray gun 5, a secondary coal feeding device 20 and a particle gasifier 17; The furnace 3 has a diameter of 1m and a height of 1.5m. Its side wall is provided with a slag inlet 2 and a slag outlet 14 , a gas outlet 18 is provided at the top, and a partition wall 15 is provided inside. The height difference between the slag outlet 14 and the bottom of the slag gasifier 3 is 100mm. The diameter of the slag inlet 2 and the slag outlet 14 is 100mm, and the height difference between them is 500mm. Partition wall 15 is rectangular, and its two sides are connected with the side wall of slag gasifier 3, and its bottom edge is connected with the bottom of slag gasifier 3, and partition wall 15 height is 550mm; Partition wall 15 and slag The horizontal distance of the 3 axes o...

Embodiment 2

[0082] The blast furnace slag composite coal gasification system adopted is the same as in Example 1, the difference is that: (1) the diameter of the slag gasifier is 3m, and the height is 6m; the distance between the slag outlet and the bottom of the slag gasifier is 500mm, and the slag The height difference between the inlet and the slag outlet is 4m; (2) the horizontal distance between the axis of the slag gasifier and the partition wall is 1.2m; the height of the partition wall is 3m, (3) the spray gun inserted into the slag gasifier is 6 4 spray guns are located at the side of the slag gasifier, two spray guns are located at the bottom of the slag gasifier, the spray guns at the bottom are perpendicular to the horizontal plane, and the 4 spray guns at the side are distributed around the side, arranged in a tangential circle, and the spray guns are aligned with the horizontal plane The included angle is 15°; the diameter of the air outlets of the four spray guns on the side...

Embodiment 3

[0086] The blast furnace slag composite coal gasification system used is the same as that in Example 1.

[0087] The blast furnace slag gasification method is the same as in Example 1, the difference is: (1) when pulverized coal and gasification agent are blown into the slag gasification furnace through the spray gun, the gasification agent is water vapor, and within the same time, it enters the slag gasification furnace. The number ratio of the O atoms in the water vapor of the slag gasifier to the C atoms in the coal powder is 0.9-1.5. (2) The gasification agent injected into the particle gasifier through the bottom spray gun is water vapor, and the flow rate is 30m / s. At the same time, the O atoms in the water vapor and The number ratio of C atoms is 0.9-1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com