Coal gasification system and method of blast furnace slags

A technology of slag gasification and blast furnace slag, applied in the direction of granular/powdered fuel gasification, joint combustion mitigation, energy input, etc., can solve the problems of no safety guarantee, deteriorating working environment, air, water and soil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

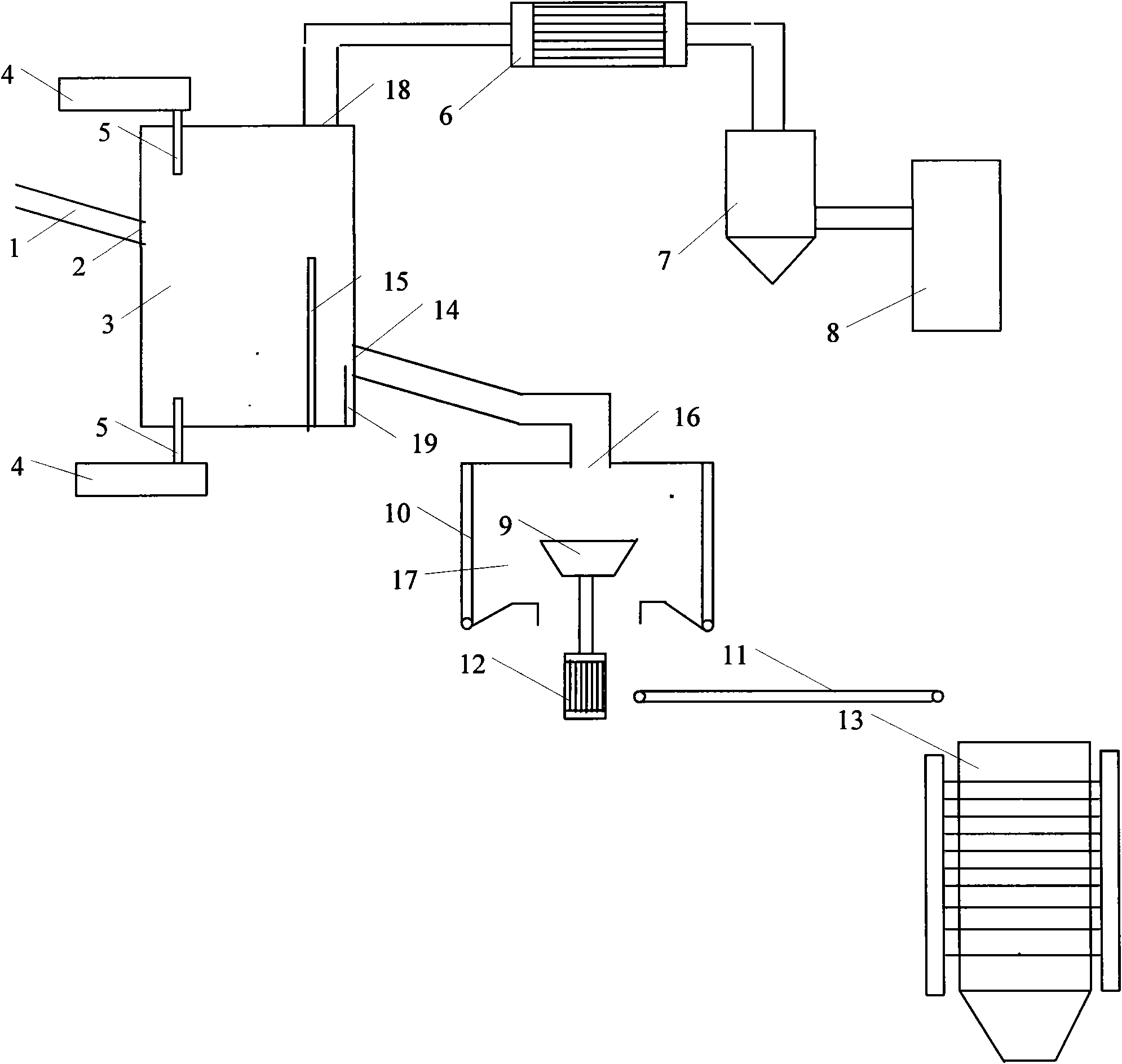

[0051] Blast furnace slag coal gasification system such as figure 1 As shown, it includes a slag gasifier 3, a coal feeding device 4, a spray gun 5, a heat exchanger 6, a gas dust collector 7, a gas storage tank 8, and a waste heat collection furnace 17; the slag gasifier 3 is provided with a slag inlet 2 , the slag outlet 14 and the gas outlet 18, the gas outlet 18 is communicated with the air inlet of the heat exchanger 6, the gas outlet of the heat exchanger 6 is communicated with the air inlet of the gas dust collector 7, and the gas outlet of the gas dust collector 7 is connected with the gas storage The gas tank 8 is connected; the slag outlet 14 is connected to the waste heat collection furnace 17 .

[0052] The interior of the slag gasifier 3 is provided with a partition wall 15, the two sides of the partition wall 15 are connected with the side walls of the slag gasifier 3, the bottom edge is connected with the bottom of the slag gasifier 3, and the partition wall 15 ...

Embodiment 2

[0064] The blast furnace slag coal gasification system is the same as that in Example 1, except that the horizontal distance between the axis of the slag gasifier and the partition wall is 80% of the diameter of the slag gasifier; (2) There are 6 coal feeding devices in the coal injection system and spray guns, where 4 spray guns are inserted into the slag gasifier at the side, 2 spray guns are inserted into the slag gasifier at the bottom, and the gas outlet diameter of the 4 spray guns inserted into the side is 8mm, and the gas outlet is connected to the furnace The distance from the bottom is 100mm, and the spray gun inserted into the side is arranged in a tangential circle, forming an angle of 15° with the horizontal plane; the diameter of the air outlet of the spray gun inserted into the bottom is 20mm, and the distance between the air outlet and the bottom of the furnace is 50mm, and the bottom spray gun is perpendicular to the horizontal plane. (2) The diameter of the sl...

Embodiment 3

[0068] The blast furnace slag coal gasification system is the same as in Example 1.

[0069] The blast furnace slag gasification method is the same as that in Example 1, except that the gasification agent is carbon dioxide, and the flow rate of carbon dioxide is 1.9-2.5 according to the ratio of the number of O atoms in carbon dioxide to C atoms in coal powder.

[0070] 43m CO produced per ton of blast furnace slag by the above method 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com