Unconventional layout form air intake and exhaust pipeline device

An unconventional air intake and exhaust technology, which is applied in measuring devices, aerodynamic tests, instruments, etc., can solve the problem that the ejector-type air intake and exhaust pipelines cannot reach the air intake and exhaust analog values, and the aerodynamic stripping of the whole machine and other problems, to achieve the effect of good air tightness, stable operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

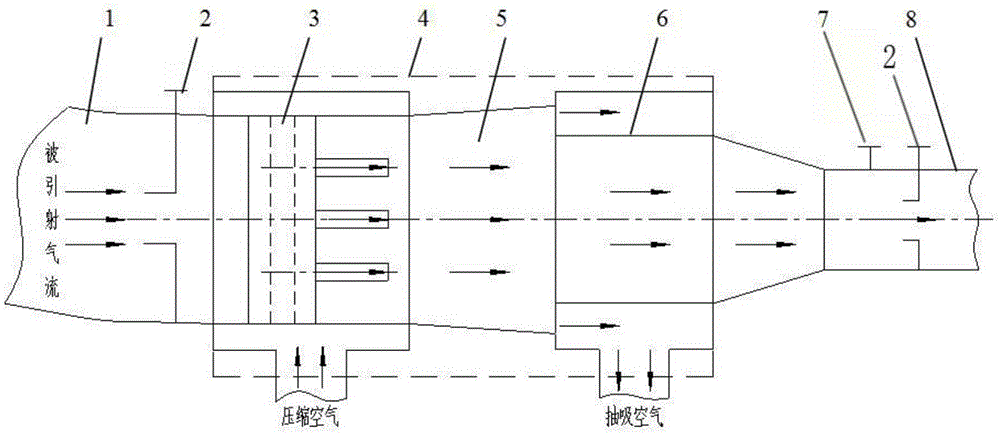

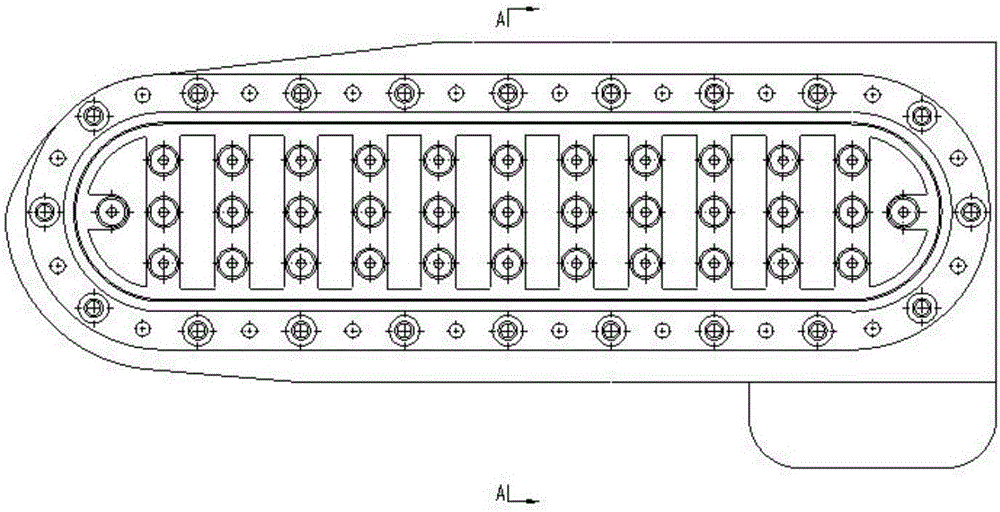

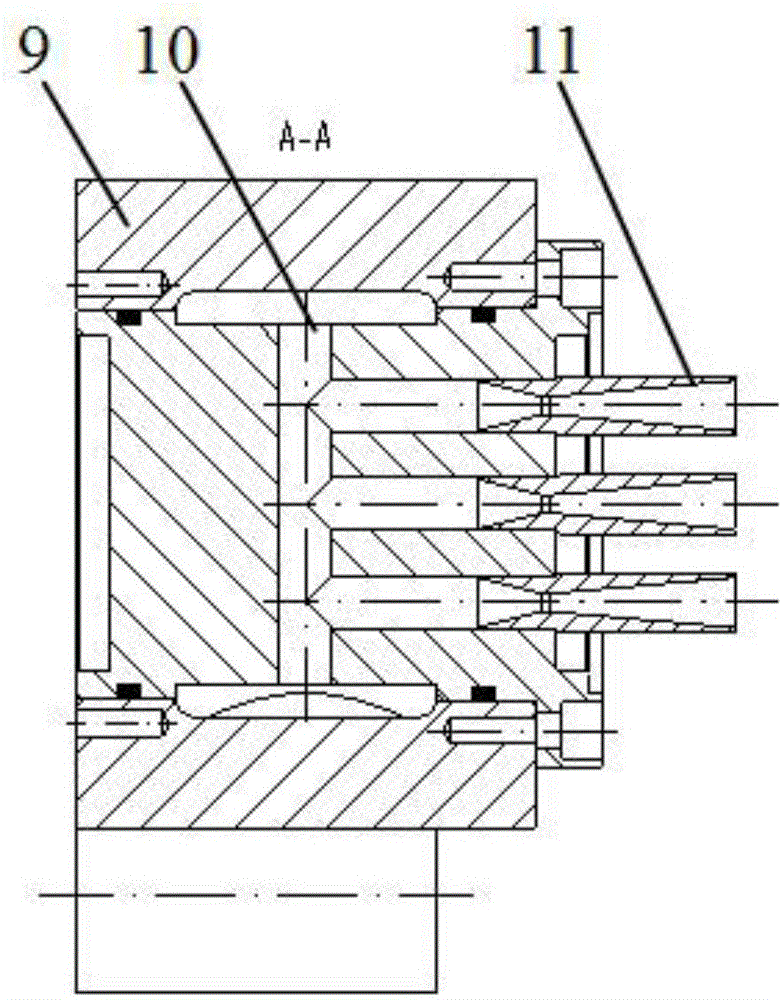

[0018] combine Figure 1-4 As shown, an intake and exhaust pipeline device with an unconventional layout, including an intake duct 1, two pressure sensors 2, an ejector 3, a core support member 4 inside the model, a diffuser tube 5, and a bypass suction pipeline 6. The temperature sensor 7 and the exhaust nozzle 8, the ejector 3, the diffuser pipe 5 and the bypass suction pipeline 6 are installed in the core support 4 inside the model, the air inlet 1 is connected with the ejector 3, and the ejector The diffuser 3 is connected with the diffuser 5, the diffuser 5 is connected with the bypass suction pipeline 6, and the bypass suction pipeline 6 is connected with the tail nozzle 8, the ejected air flow enters from the air inlet 1, and the compressed air enters from the induced The injector 3 enters, the bypass suction pipeline 6 uses the pressure difference inside and outside the pipeline to freely drain, the first pressure sensor 2 is installed on the inlet channel 1, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com