Circulation type dismounting and washing free cooking-fume exhauster

A range hood, no dismantling and cleaning technology, applied in the removal of range hood, heating method, household stove/stove, etc., can solve the problems of noise pollution, uneven oil accumulation of fan impellers, decreased efficiency of hoods, etc., to reduce labor intensity , obvious energy-saving effect, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

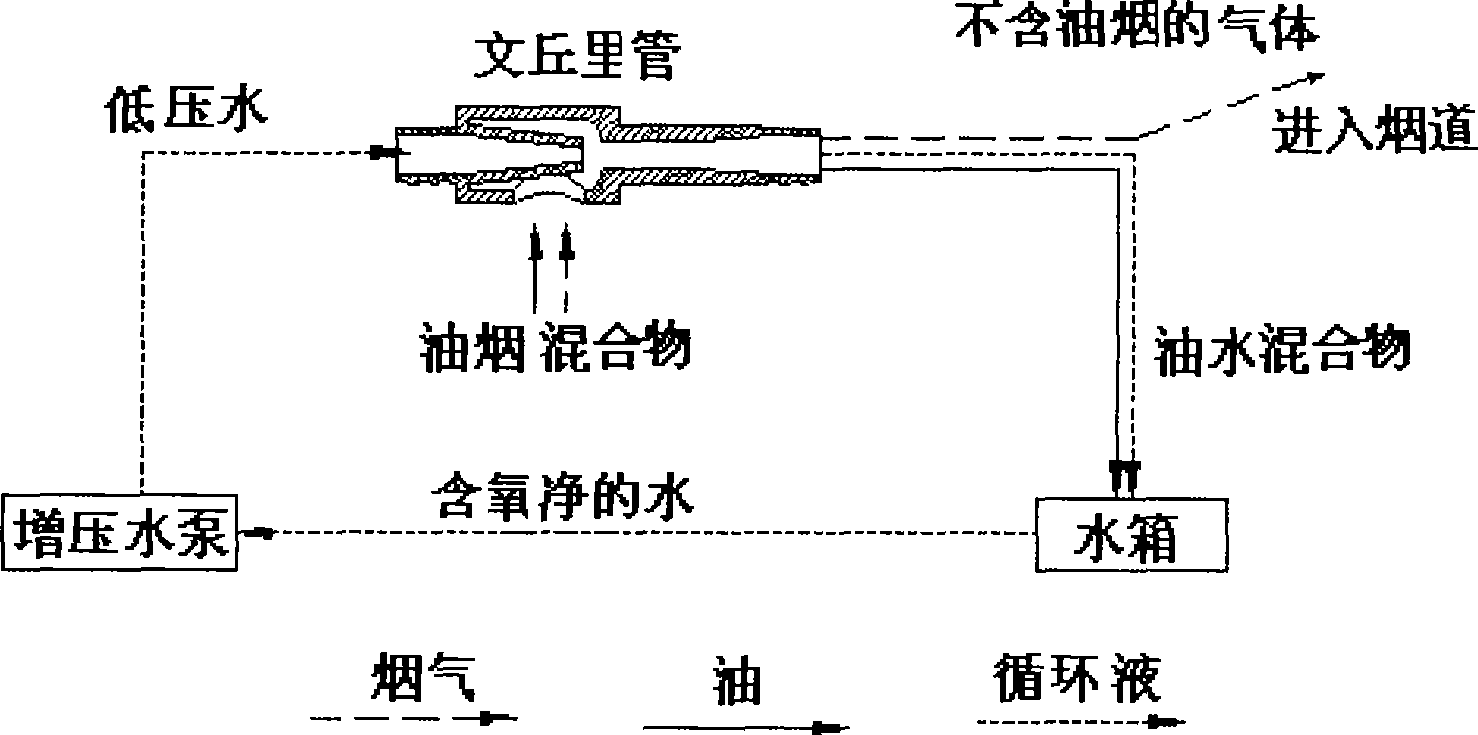

Method used

Image

Examples

Embodiment 1

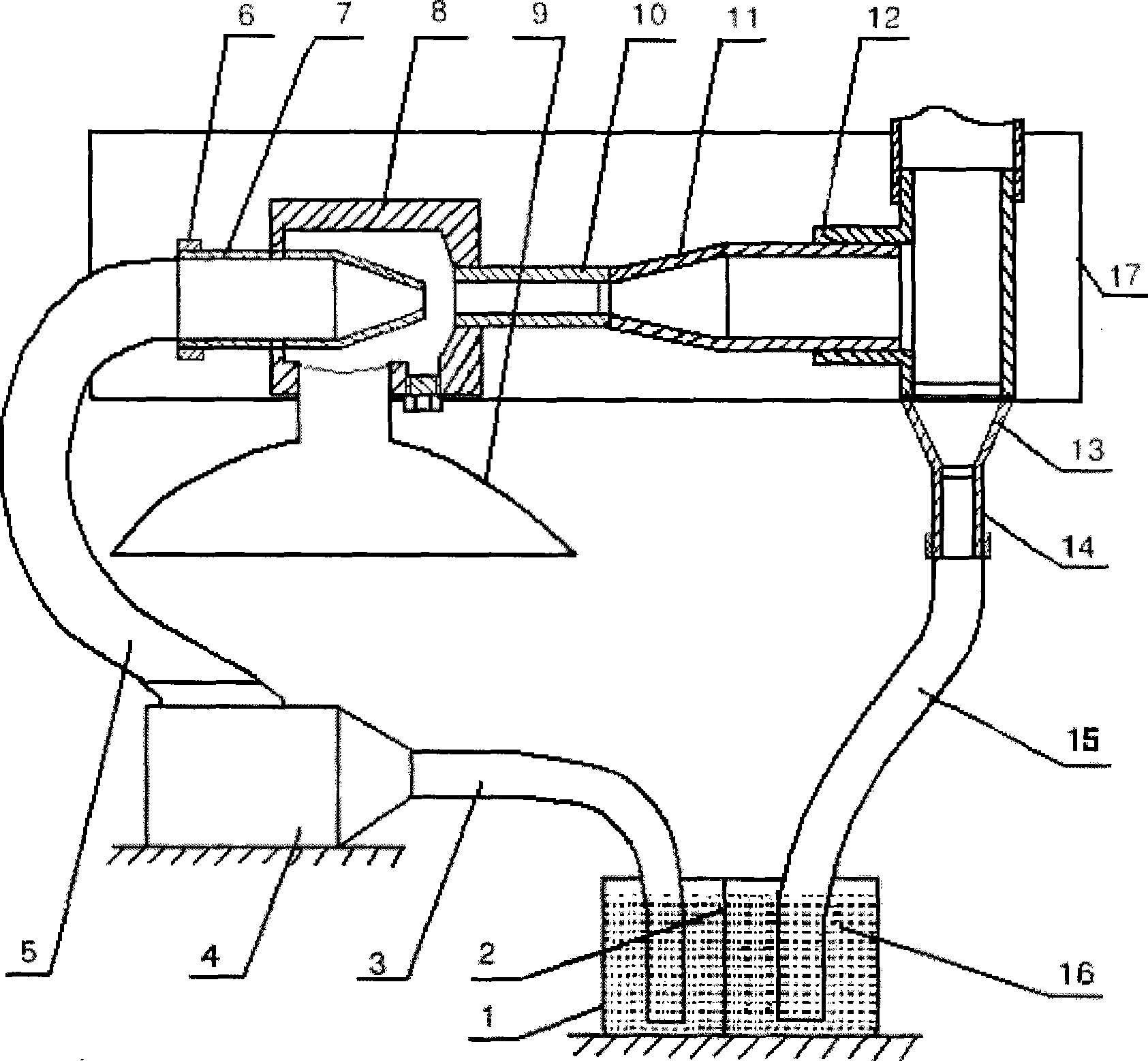

[0021] Embodiment 1: Assembling the circulating type non-disassembly and cleaning range hood of the present invention, the structure is as follows figure 2 As shown, the volume of the water tank 1 used: 200mm×350m×240mm, the grid plate 2 has a grid, and the automatic booster pump 4: power 125W; maximum head 33m; maximum flow 33L / min; water inlet pipe 3, outlet pipe 5, pipe clamp 6 and the return hose 15 are commercially available products; the nozzle 7, the mixing chamber 8, the mixing pipe 10 and the diffuser pipe 11 are made of engineering plastics, and the distance between the outlet of the nozzle and the inlet of the mixing chamber is twice the diameter of the outlet of the nozzle. The pipe diffusion angle is 9°, and the four parts are sealed and connected by thread and raw tape to form a Venturi tube structure. The oil fume collection cover 9 is fixed on the mixing chamber; the tee pipe 12, the big and small head 13, the straight pipe section 14, and the circulating water...

Embodiment 2

[0029] Embodiment 2: The effect of the range hood of the present invention compared with the traditional range hood is shown in the following table:

[0030] traditional range hood this invention Price (yuan) 2000~5000 (market selling price) 600 (cost price) Vacuum (Pa) 200~300 1200~1500 Motor power (W) 200~220 125 to clean washable Dismantling and washing Environmental friendly Oil fume direct exhaust pollutes the atmosphere No fume pollution

[0031] From the perspective of energy saving and emission reduction, a preliminary estimate, using the present invention, 1. the total amount of oil fume discharged by Chinese families every year can be reduced by about 3 × 10 14 cubic meter. ②Because it does not need to be disassembled and cleaned, the water resources, manpower and material resources for cleaning traditional range hoods are greatly reduced, and Chinese families can save about 9 million tons of water resources ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com