Closed test device for NPSH of submersible pump

A technology of closed-type and test device for NPSH, applied in the field of fluid machinery, can solve the problem that the total suction head cannot be measured, the measurement method of the NPSH of the submersible pump is not specifically provided, and the test method of the cavitation performance of the submersible pump is not provided, etc. problem, to achieve the effect that the solution cannot be carried out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

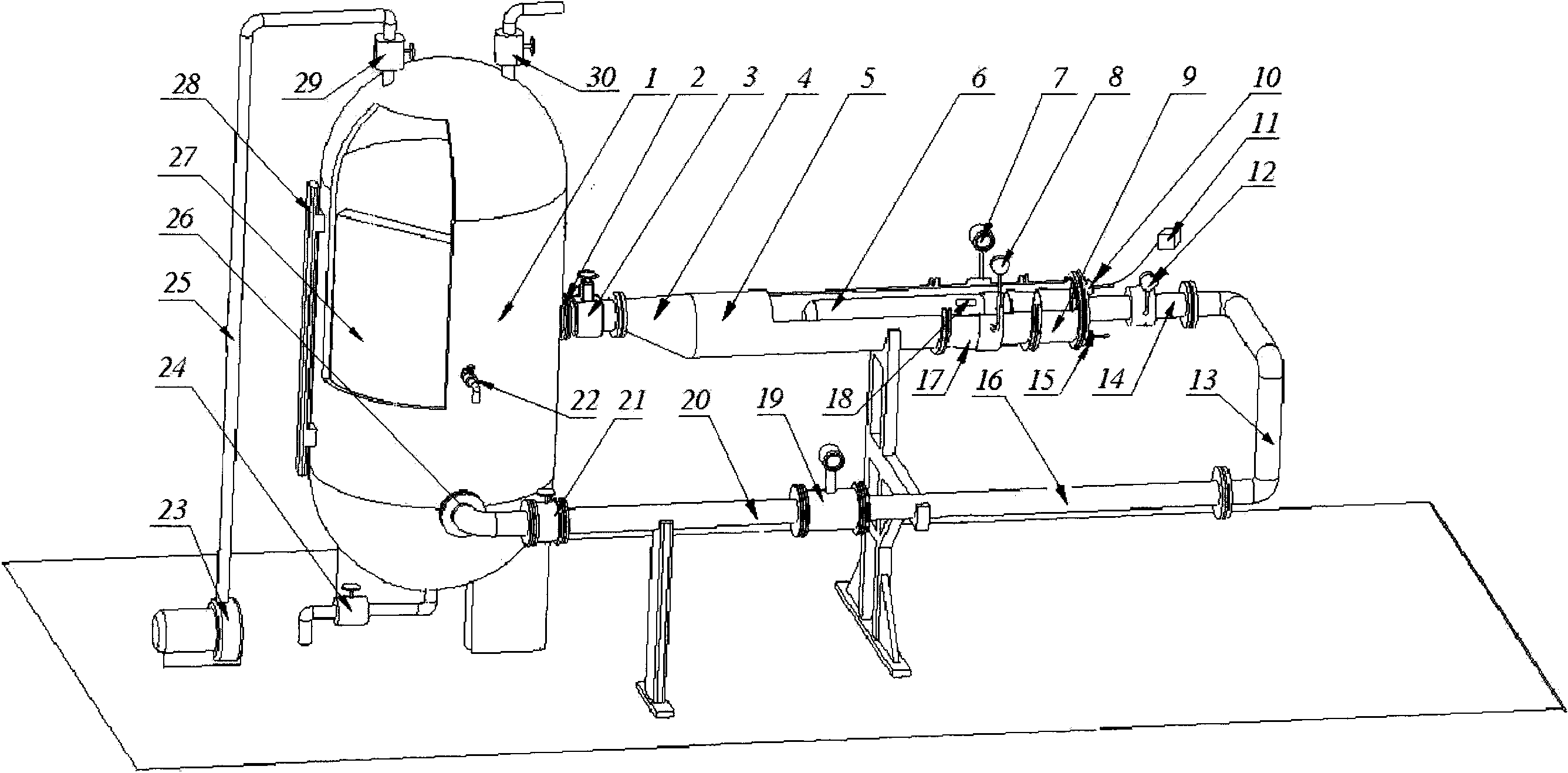

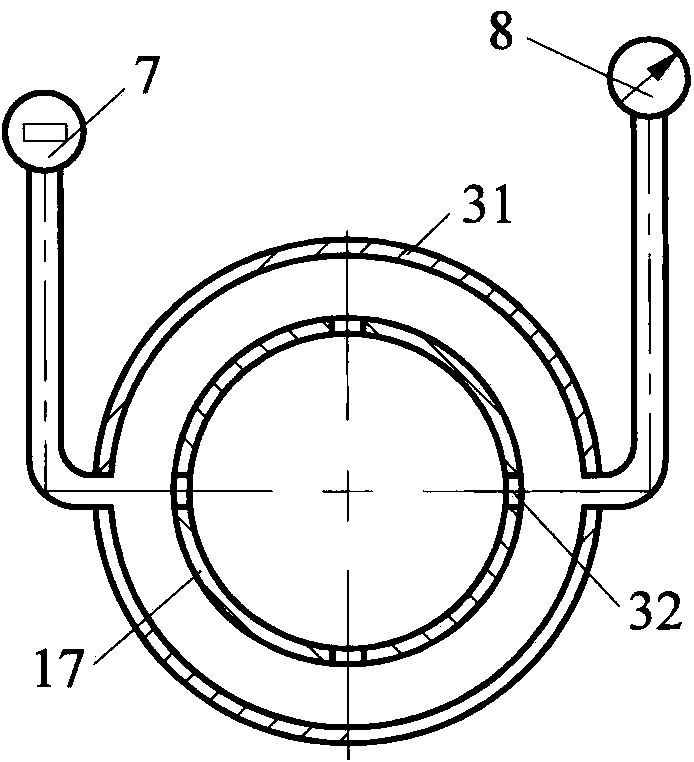

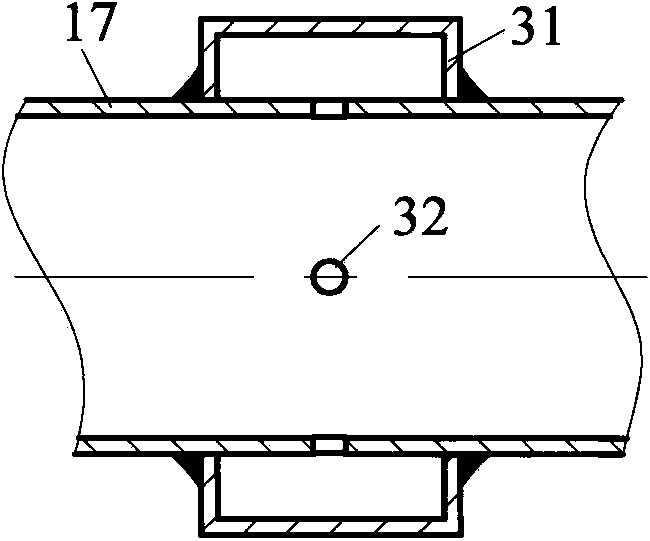

[0016] see figure 1 , submersible pump NPSH closed-type test device consists of cavitation tank 1, outlet 2, inlet valve 3, non-centric diffusion pipe 4, suction pipe 5, submersible pump 6, thermometer 7, inlet pressure gauge 8, transition pipe 9 , sealing joint one 10, speed measuring instrument 11, outlet pressure gauge 12, drain pipe 13, outlet pressure measuring tube 14, sealing joint two 15, flow meter upstream straight pipe section 16, inlet pressure measuring tube 17, speed sensor 18, flow meter 19. The straight pipe section 20 downstream of the flow meter, the flow regulating valve 21, the water injection valve 22, the vacuum pump 23, the drain valve 24, the air extraction pipe 25, the separator 27, the liquid level gauge 28, the air extraction valve 29, and the exhaust valve 30. One end of the inlet valve 3 is flanged to the outlet 2, and the other end is flanged to the heterocentric diffusion pipe 4. The diffusion end of the heterocentric diffusion pipe 4 is welded t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com