Injection-type reactor for preparing gas hydrates

A technology of jet reactor and gas hydrate, applied in the direction of fluid mixer, mixer, chemical instrument and method, etc., can solve the problem of affecting the formation rate of gas hydrate, increasing blowing power and stirring power, gas hydrate The synthesis is not continuous, etc., to achieve the effect of shortening the hydration induction time, increasing the solubility, and improving the hydration reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

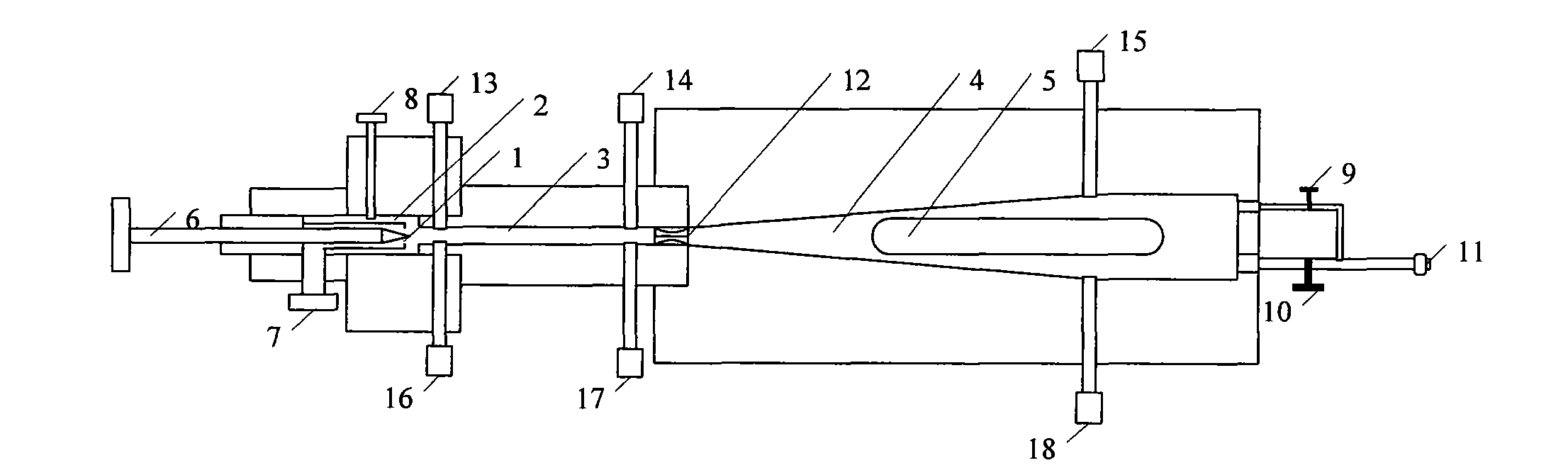

[0025] A jet reactor for preparing gas hydrate, which is composed of four parts: nozzle 1, entrainment chamber 2, throat pipe 3 and diffusion pipe 4, and its exterior is equipped with window 5, needle valve 6, reaction water inlet 7, and gas inlet 8. Gas valve 9, valve 10, gas-liquid outlet 11, flow control valve 12, temperature sensors (13, 14, 15) and pressure sensors (16, 17, 18).

[0026] A needle valve 6 for adjusting the area of the nozzle 1 is provided in the reactor water inlet pipe, and the needle valve 6 is screwed forward by rotating the valve handle of the needle valve 6, and the gap between the needle head and the nozzle 1 gradually decreases; The valve handle of the valve 6 makes the needle valve 6 rotate forward to adjust the size of the gap between the needle and the nozzle 1 to control the flow of water inflow, which can completely cut off the water flow in from the reaction water inlet 7. The gas inlet 8 connected to the suction chamber 2, the entrainment c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com