Adjustable multi-streaming type steam jet heat pump

A steam and heat pump technology, applied in the direction of jet pumps, pumps, non-volume pumps, etc., can solve the problems of large energy level difference, low heat pump efficiency, mechanical energy loss, etc., to reduce mechanical energy loss, improve heat pump efficiency, and reduce impact loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

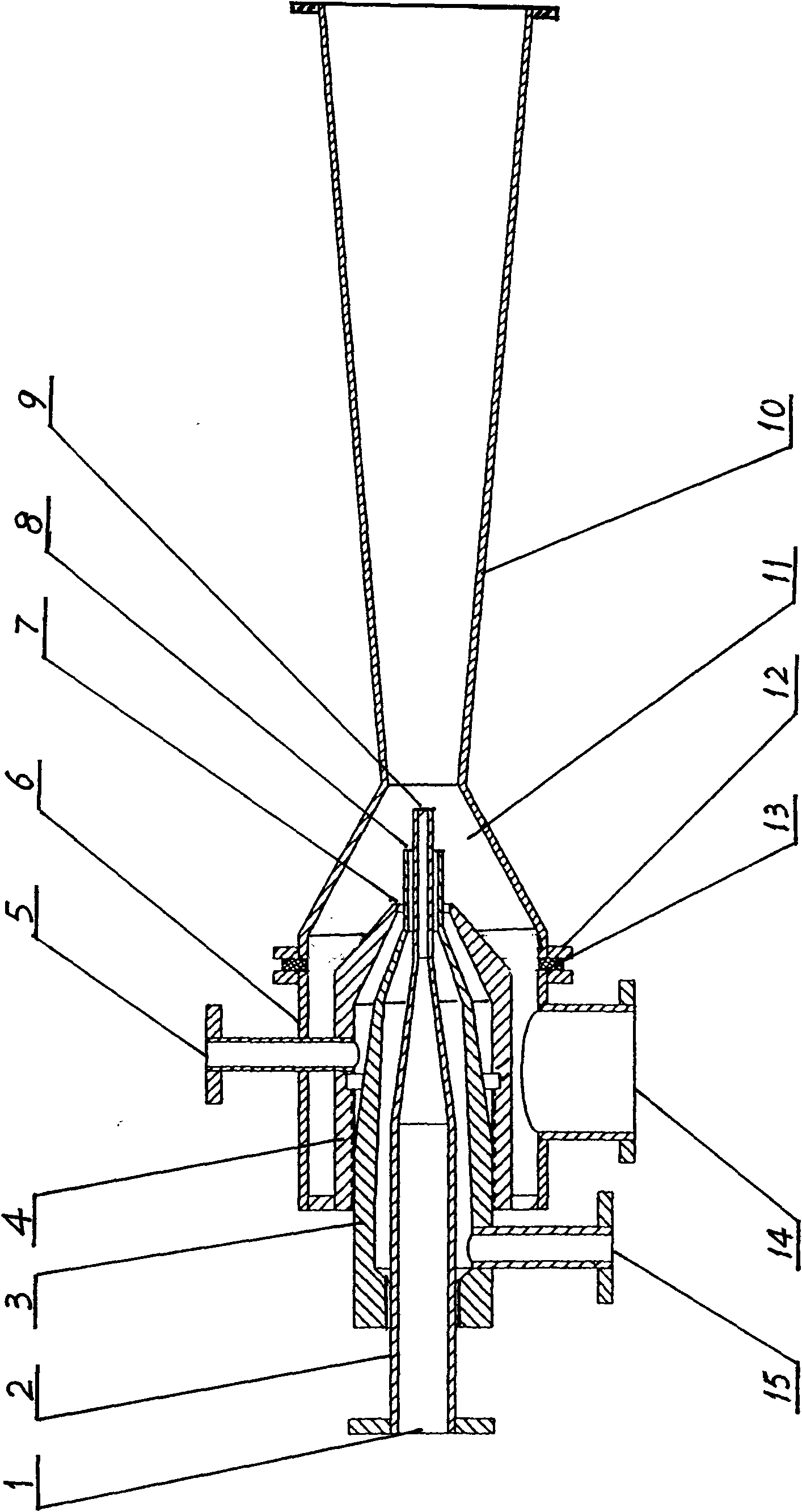

[0018] Such as figure 1 As shown, an adjustable multi-flow steam jet heat pump includes a pump body 6 in the structure. The pump body 6 is composed of a barrel-shaped shell and a cone-shaped pump port. The barrel-shaped shell and the cone-shaped pump port pass through The flange 12 is connected with a gasket 13 in the middle. By changing the thickness of the gasket 13, the distance between the outlet of the mixing chamber and the nozzle opening can be adjusted. The outer end of the cone-shaped central nozzle 2 located in the center of the pump body is provided with a working steam inlet 1. On the outer side of the cone-shaped central nozzle 2, one or more cone-shaped surrounding nozzles 3 with closed bottom ends are coaxially sleeved and fixed. 4. Commonly used are 2 to 3, the central nozzle and the surrounding nozzles and the surrounding nozzles are screwed together for easy installation and adjustment. A steam cavity is formed between the inner and outer cylinder walls of th...

Embodiment 2

[0020] This embodiment is an example of the use of an adjustable multi-flow steam jet heat pump. In the process of evaporation and concentration of a thermally sensitive material aqueous solution, the process requires that the evaporation temperature must be lower than 95°C. Double-effect evaporator is used. The first effect vacuum degree is 0.04MPa, the material temperature is 92°C, and the second steam temperature is 88°C; the second effect The vacuum degree is 0.095MPa, the material temperature is 80°C, and the secondary steam temperature is 70°C. The first effect uses 0.35MPa steam heating, and the second steam is pressurized by the steam jet heat pump as the second effect evaporator heating source. Using the adjustable three-flow steam jet heat pump described in Example 1 of the utility model, the working steam pressure of the central nozzle is 0.35MPa, the working steam pressure of the first annular nozzle is 0.25MPa, and the working steam pressure of the second annular n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com