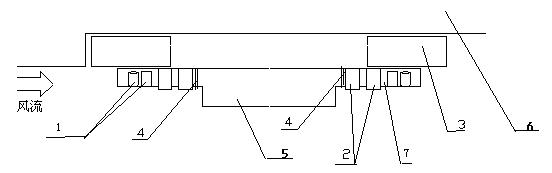

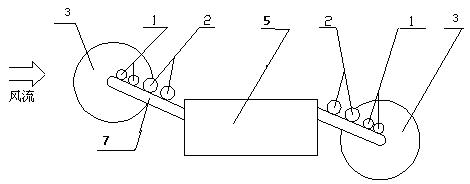

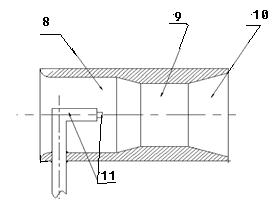

Induced draft water curtain dust removing device for intercepted coal mining machine

A technology of dust suppression device and shearer, applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of unreasonable number of nozzles, nozzle structure, dust reverse flow, poor atomization effect, etc., to increase the chances of capturing dust and Time, eliminate dust countercurrent, good effect of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now mainly introduce the implementation example of the present invention in the 3410 comprehensive mechanized coal mining face of Qinan Coal Mine.

[0023] The working face is located in the northern part of the minefield, the working face elevation is -552.9m ~ -612.4m, and it is located in the second section of the right wing of the 34 lower mining area. The volatile content of the coal seam is more than 30%, and the coal dust has the risk of explosion. It is a coal seam that is extremely prone to spontaneous combustion and non-spontaneous combustion. The gas content of the working face is 6.0-7.3ml / g, with an average content of 6.6ml / g, and there are local gas-enriched areas During coal mining, the gas concentration in the upper corner is 0.4-0.7%, and the gas concentration in the return air is 0.3-0.5%. Adopting the longwall comprehensive mechanized coal mining method, the full height is mined at one time, and the maximum mining height is 3.8m. When the coal thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com