High-lift multi-stage side channel pump with gas-liquid mixed flow

A high-lift, side channel technology, applied to radial flow pumps, parts of pumping devices for elastic fluids, pumps, etc., can solve the problems affecting reliability and safety, side channel pumps cannot operate, Poor cavitation ability and other problems, to avoid energy loss, improve hydraulic performance and anti-cavitation ability, eliminate backflow or deflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

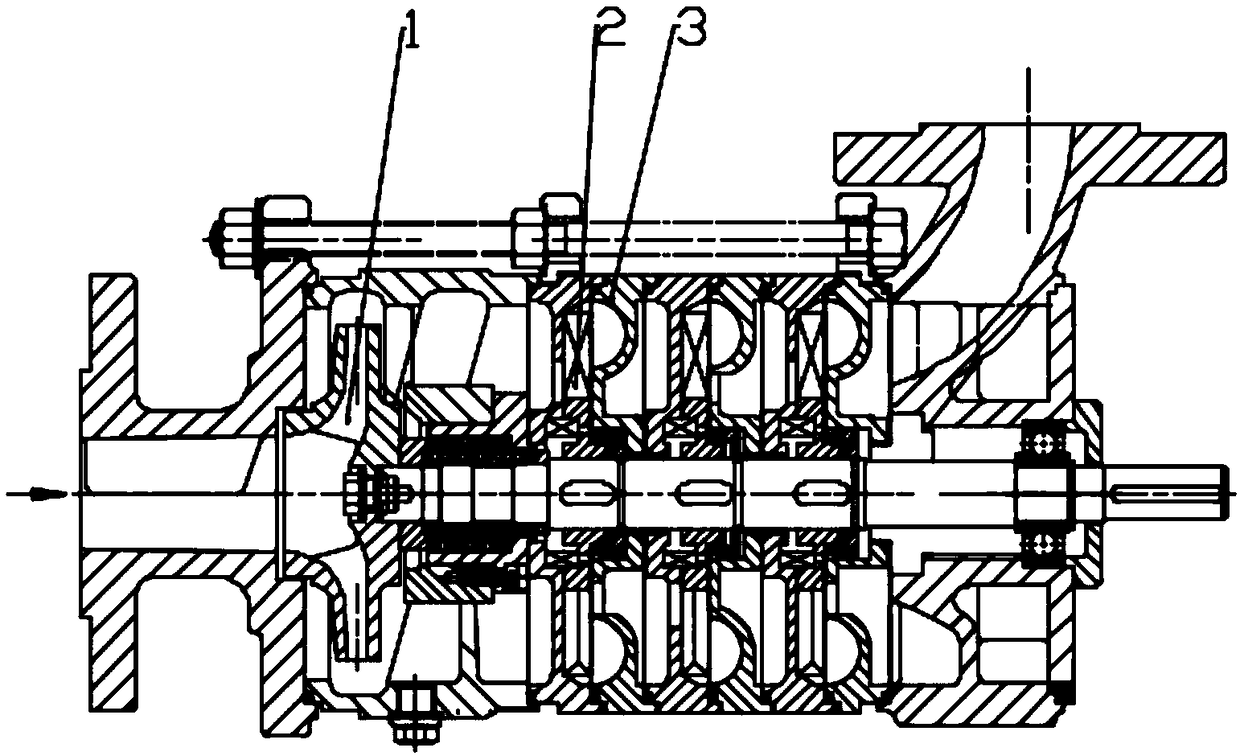

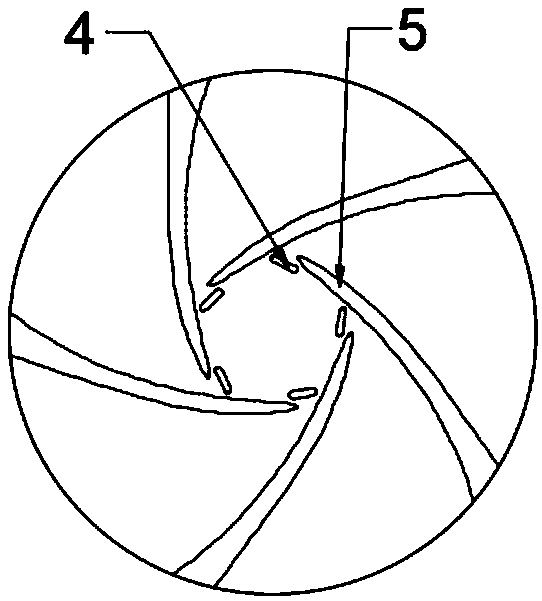

[0022] combined with figure 1 The schematic diagram of the structure of the multi-stage side channel pump is shown. The main components of the multi-stage side channel pump are the first stage impeller 1, the radial star impeller 2, and the arc flow channel 3; the fluid enters from the first stage impeller 1, and the gap drainage impeller shows Such as figure 2 As shown, when the fluid flows into the first-stage impeller 1, because there is a gap between the leading vane 4 and the trailing vane 5, part of the fluid will flow from the pressure side of the blade to the suction side through the gap, and because the deflection of the leading vane 4 If the position is set, the area of the inlet area of the flow channel will increase, making the distribution of the velocity field inside the flow channel more uniform, which will also eliminate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com