Self-oscillation pulsed liquid-gas jet pump

A technology of liquid-air jet pump and self-excited oscillation, which is applied in jet pumps, pumps, non-volume pumps, etc., can solve the problems of low energy transfer efficiency and limit popularization and application, and achieve simple structure, high efficiency, and sufficient liquid-gas mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

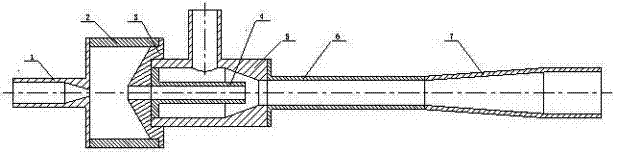

[0014] see figure 1 , the self-excited oscillation pulse liquid-air jet pump includes an upper nozzle (1), a self-excited oscillation chamber (2), a collision body (3), a lower nozzle (4), a suction chamber (5), a throat (6), The diffusion pipe (7), characterized in that the upper nozzle (1), the self-excited oscillation chamber (2), the collision body (3), and the lower nozzle (4) are sequentially connected to form a self-excited oscillation pulse jet nozzle; the self-excited oscillation The pulse jet nozzle, the suction chamber (5), the throat pipe (6), and the diffusion pipe (7) are connected in sequence to form a jet pump.

Embodiment 2

[0016] This embodiment is basically the same as Embodiment 1, and the special feature is: the self-excited oscillating pulse liquid-air jet pump, which is characterized in that: one end of the collision body (3) is designed as a concave hole, and is directly connected to the suction chamber ( 5) One end is connected; the lower nozzle (4) is located inside the suction chamber (5); the ratio of the area of the lower nozzle (4) to the area of the throat (6) is 1:3-8; the throat (6) ) ratio of inner diameter to length is 1:6-8; the ratio of cavity length to cavity diameter of the self-excited oscillation cavity (2) is 1:0.4-0.7; the upper end of the collision body (3) is a cone, the The taper of the cone is 120°±10°; the diameter ratio of the upper nozzle (1) and the lower nozzle (4) is 1:2.0~2.2;

Embodiment 3

[0018] Such as figure 1 As shown, the self-excited oscillation pulse liquid-air jet pump includes an upper nozzle (1), a self-excited oscillation chamber (2), a collision body (3), a lower nozzle (4), a suction chamber (5), a throat (6 ), diffusion pipe (7), characterized in that the upper nozzle (1), self-excited oscillation cavity (2), collision body (3), and lower nozzle (4) form a self-excited oscillation pulse jet nozzle; self-excited oscillation The pulse jet nozzle is connected to the suction chamber (5), and the lower nozzle (4) is located inside the suction chamber (5); one end of the throat pipe (6) is connected to the suction chamber (5), and the other end is connected to the diffuser pipe (7) to form a jet pump.

[0019] The working process of the self-excited oscillating pulse liquid-air jet pump is: the constant jet flow from the upper nozzle (1) enters the self-excited oscillation cavity (2), and the vorticity disturbance in the jet flow within a certain freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com