Biodegradable nerve conduit with bilayer structure and preparation method thereof

A technology of nerve conduit and double-layer structure, which is applied in the field of biodegradable nerve conduit and its preparation, can solve problems such as the influence of mechanical properties, and achieve the effects of promoting regeneration and repair, high economic benefits, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

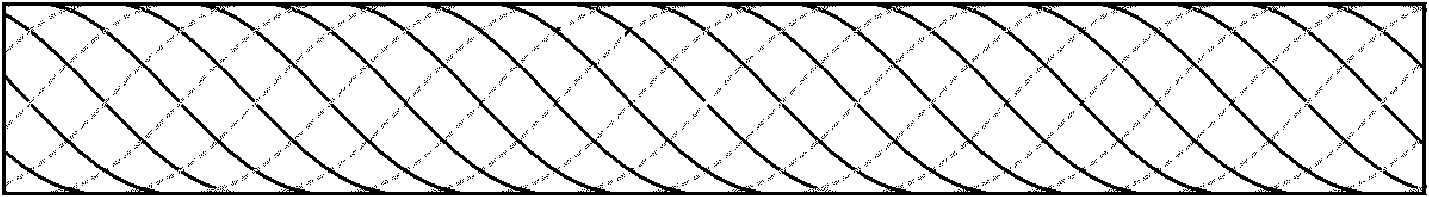

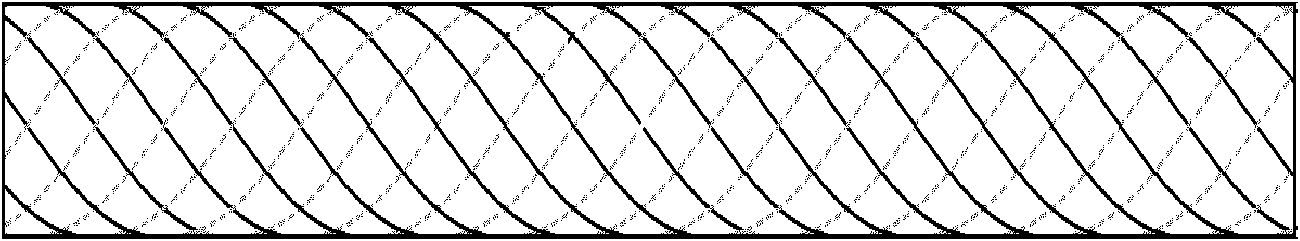

[0027] (1) The PGLA monofilament obtained by melt spinning is braided into a mesh circular tube with an inner diameter of 2 mm, which is inserted into the rotating receiving circular tube of the electrospinning machine device after being fixed-length and shaped, and the rotation speed is 4000 rpm;

[0028] (2) PLA is dissolved in tetrahydrofuran / DMF solution (tetrahydrofuran: the volume ratio of DMF=3: 1), after stirring, it is PLA / tetrahydrofuran / DMF solution with 6% PLA mass percentage to make; silk fibroin is dissolved in three In the fluoroacetic acid solution, the silk fibroin protein mass percentage is 10% spinning stock solution after stirring;

[0029] (3) Import the above two spinning stock solutions into two syringe pumps respectively. The two syringe pumps have two nozzles with the same axis inside and outside to carry out electrospinning. Adjust the flow rate of the propulsion pump to 1.3mL / h and apply high pressure. 10kv, the receiving distance is 18cm;

[0030] ...

Embodiment 2

[0032] (1) The PGLA monofilament obtained by melt spinning is braided into a mesh circular tube with an inner diameter of 2 mm, which is inserted into the rotating receiving circular tube of the electrospinning machine device after being fixed-length and shaped, and the rotation speed is 4000 rpm;

[0033] (2) Dissolve PBS / PCL (mass ratio 1:4) in chloroform solution, stir to make PBS / PCL / chloroform solution with solute mass fraction of 10%; dissolve gelatin in formic acid solution, stir to make Gelatin mass fraction is the spinning stock solution of 10%;

[0034] (3) Import the two kinds of spinning stock solutions into two syringe pumps respectively. The two syringe pumps have two nozzles with the same axis inside and outside to carry out electrospinning. The flow rate of the propulsion pump is adjusted to 1.3mL / h, and the high pressure is 7.53kv, the receiving distance is 18cm;

[0035] (4) After electrospinning, the nerve guide was removed, sterilized by cobalt 60 irradiat...

Embodiment 3

[0037] (1) The PGLA monofilament obtained by melt spinning is braided into a mesh circular tube with an inner diameter of 0.5mm, and after being fixed-length and shaped, it is inserted into the rotating receiving circular tube of the electrospinning machine device, and the rotation speed is 4000rpm;

[0038] (2) Dissolve PBS / PLA (mass ratio 1:4) in chloroform solution, stir to make PBS / PLA / chloroform solution with solute mass fraction of 10%; dissolve gelatin in formic acid solution, stir to make Gelatin mass fraction is the spinning stock solution of 10%;

[0039] (3) Import the two kinds of spinning stock solutions into two syringe pumps respectively. The two syringe pumps have two nozzles with the same axis inside and outside to carry out electrospinning. Adjust the flow rate of the propulsion pump to 1.3mL / h, and apply high pressure to 8kv, the receiving distance is 18cm;

[0040] (4) After the electrospinning, the nerve guide was removed, sterilized by irradiation with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com