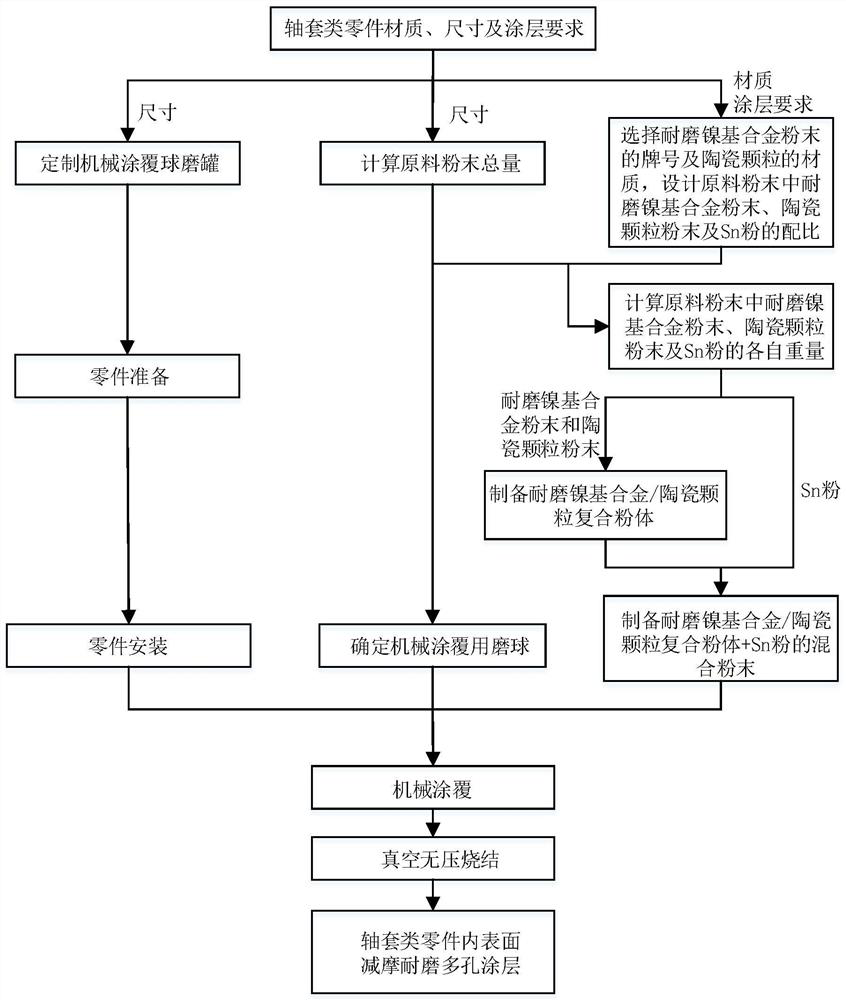

A method for preparing a friction-reducing and wear-resistant porous coating on the inner surface of a shaft sleeve part

A technology of porous coating and inner surface, applied in coating, metal material coating process and other directions, can solve the problems of large residual stress, high working temperature of heat source, weakened coating performance, etc., to achieve easy industrial production, coating heat Effects of low stress and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

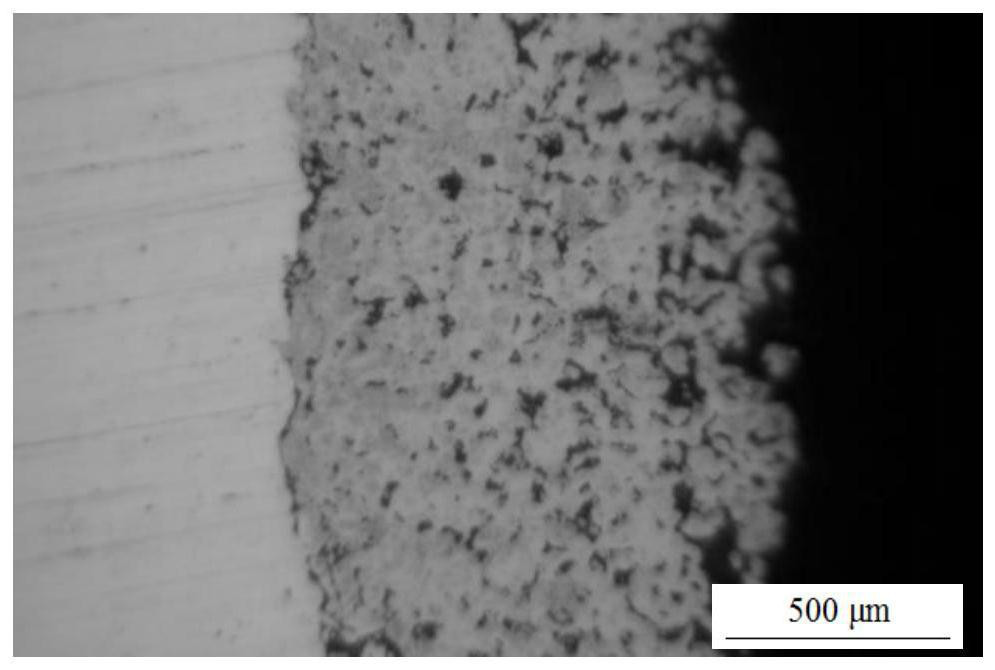

Examples

Embodiment 1

[0060] The material of the shaft sleeve parts is copper, the inner diameter is 100mm, the height is 100mm, the thickness is 10mm, and the inner surface area is 31400mm 2 , the coating hardness is required to be greater than HRC20, the porosity is 10-14%, and the coating thickness is 0.8-1.2mm.

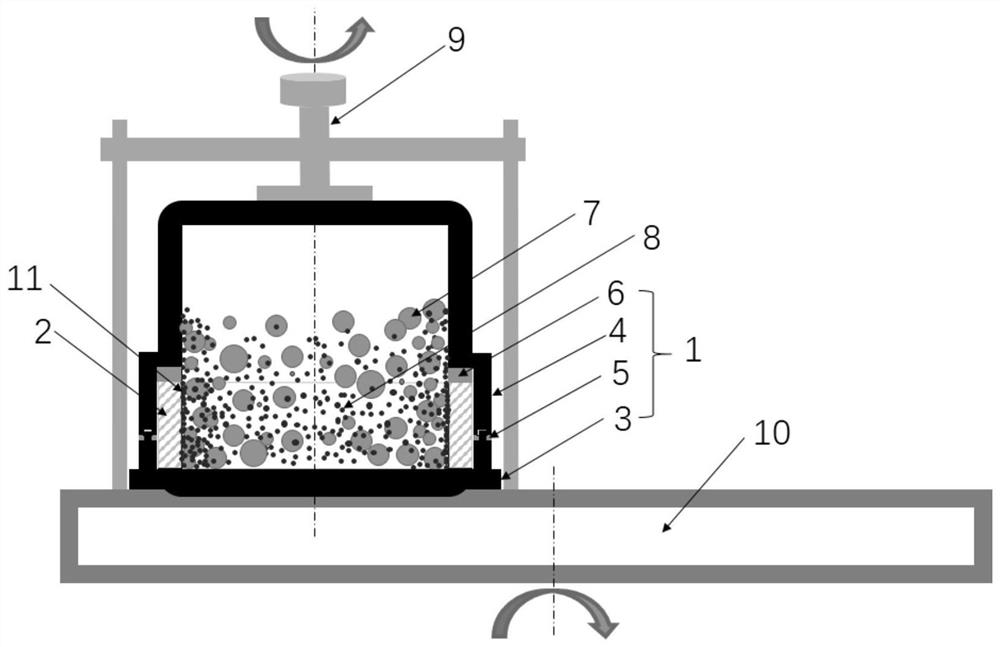

[0061] The structure of the ball mill is as follows figure 2 As shown, the height of the tank body is 220mm, the thickness of the rubber sealing gasket is 0.5mm, and the thickness of the rubber compression gasket is 5mm.

[0062] The total amount of raw material mixed powder is: 31400*0.010=314(g).

[0063] The grade of wear-resistant nickel-based alloy powder is selected as Ni25, and the mass percentage of Ni25 is composed of: C 0.1%, Cr 0, Fe≤8%, Si 3.5%, B 1.5%, Ni balance; the material of ceramic particle powder is WC.

[0064] The ratio of three components such as Ni25 powder, WC powder and Sn powder in the raw material mixed powder is: (Ni25 0.85 WC 0.15 ) 0.84 sn 0.16 , w...

Embodiment 2

[0073] The shaft sleeve parts are made of low carbon steel Q235, with an inner diameter of 100mm, a height of 100mm, a thickness of 10mm, and an inner surface area of 31400mm 2 , the coating hardness is required to be greater than HRC45, the porosity is 10-14%, and the coating thickness is 0.8-1.2mm.

[0074] Using the same parameters as in Example 1, the grade of wear-resistant nickel-based alloy powder is selected as Ni60, and the mass percentage of Ni60 is composed of: C 0.8%, Cr 16%, Fe≤15%, Si 4.5%, B 3.5%, Ni balance ; Select the material of the ceramic particle powder as WC.

[0075] The ratio of three components such as Ni60 powder, WC powder and Sn powder in the raw material mixed powder is: (Ni60 0.8 WC 0.2 ) 0.84 sn 0.16 , wherein, the particle size of Ni60 powder is less than 50 μm; the particle size of WC powder is less than 5 μm; the particle size of Sn powder is less than 20 μm, and the purity is greater than 99.5%.

[0076] The raw material mixed powder ...

Embodiment 3

[0079] The material of the shaft sleeve parts is copper, the inner diameter is 100mm, the height is 100mm, the thickness is 10mm, and the inner surface area is 31400mm 2 , the coating hardness is required to be greater than HRC20, the porosity is 18-25%, and the coating thickness is 0.8-1.2mm.

[0080] Using the same parameters as in Example 1, the grade of wear-resistant nickel-based alloy powder is selected as Ni25, and the mass percentage of Ni25 is composed of: C 0.1%, Cr 0%, Fe≤8, Si 3.5%, B 1.5%, Ni balance; Select the material of the ceramic particle powder as WC.

[0081] The ratio of three components such as Ni25 powder, WC powder and Sn powder in the raw material mixed powder is: (Ni25 0.85 WC 0.15 ) 0.73 sn 0.27 , wherein, the particle size of Ni25 powder is less than 50 μm; the particle size of WC powder is less than 5 μm; the particle size of Sn powder is less than 20 μm, and the purity is greater than 99.5%.

[0082] The raw material mixed powder contains 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com