Method for preparing cellulose fiber using ion liquid as solvent

A technology of cellulose fibers and ionic liquids, applied in spinning solution preparation, fiber treatment, textiles and papermaking, etc., can solve the problems of strong corrosion and volatility of solvents, reduce production costs, shorten process flow, and facilitate recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

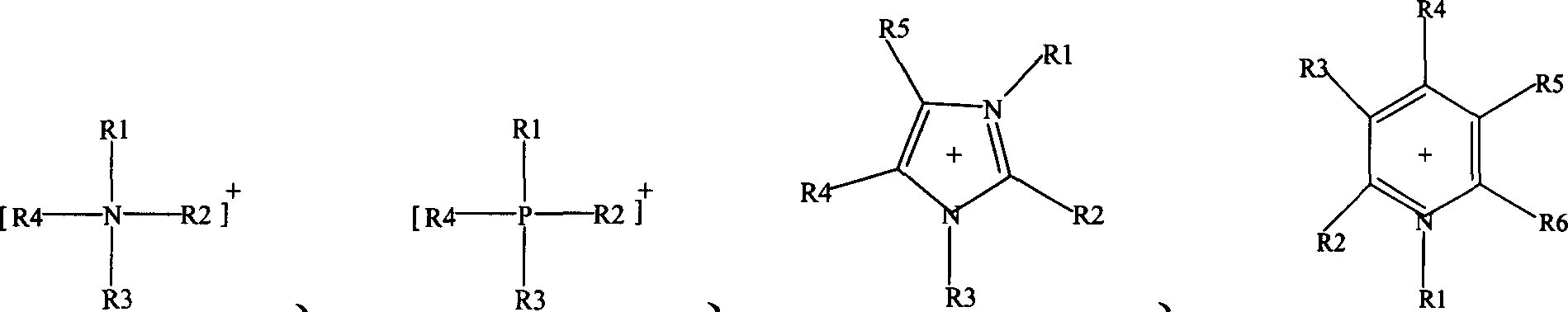

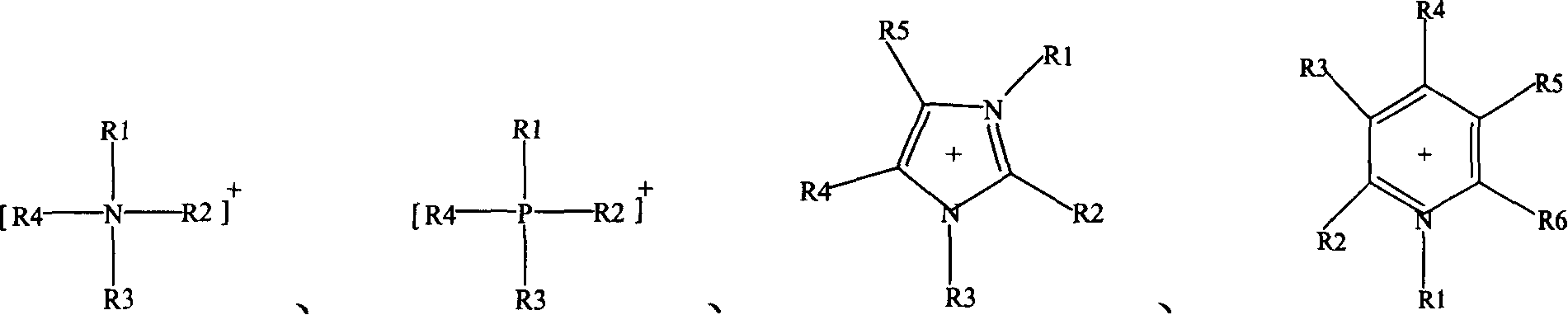

Method used

Image

Examples

Embodiment 1

[0027] Mix the pulverized wood pulp and ionic liquid evenly, and dissolve it at 90°C for 24 hours to form a uniform and stable spinning stock solution. The concentration of the spinning stock solution is 5%. The spinning stock solution is filtered and defoamed before wet spinning , the coagulation bath is an aqueous solution of [BMIM]Cl (the Chinese name is 1-butyl-3-methylimidazolium chloride), the concentration of the ionic liquid in the coagulation bath is 10%, and the temperature is 30°C.

[0028] The spinning speed is 10m / s, and the solidified fiber is processed by washing, stretching, oiling, drying and other procedures to obtain a cellulose fiber with a strength of 5.8cN / dtex.

Embodiment 2

[0030] Mix the pulverized bamboo pulp and ionic liquid evenly, and dissolve it for 100 hours at 50°C to form a uniform and stable spinning stock solution. The concentration of the spinning stock solution is 35%, and the spinning stock solution is filtered and defoamed for melt-blown wet spinning , the coagulation bath is [AMIM]Cl (Chinese name 1-propenyl-3-methylimidazolium chloride) ionic liquid aqueous solution, the concentration of the ionic liquid in the coagulation bath is 50%, and the coagulation bath temperature is 90°C.

[0031] The spinning speed is 8m / s, and the solidified fiber is processed by washing, stretching, oiling, drying and other procedures to obtain a cellulose fiber with a strength of 4.3cN / dtex.

Embodiment 3

[0033] Mix the pulverized cellulose acetate pulp and ionic liquid evenly, and dissolve it for 1 hour at 150°C to form a uniform and stable spinning stock solution. The concentration of the spinning stock solution is 20%, and the spinning stock solution is filtered and defoamed before spinning. Silk, the coagulation bath is [BMIM]Br (Chinese name 1-butyl-3-methylimidazolium bromide) ionic liquid aqueous solution, the concentration of the ionic liquid in the coagulation bath is 5%, and the coagulation bath temperature is 0°C.

[0034] The spinning speed is 15m / s, and the coagulated fiber is processed by washing, stretching, oiling, drying and other procedures to obtain a cellulose fiber with a strength of 2.3cN / dtex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com