Zinc-ferrite-based nanometer composite as well as preparation method and application thereof

A nano-composite material and nano-particle technology, which is applied in the field of lithium-ion battery anode materials and lithium-ion batteries, can solve the problems of poor compatibility of organic electrolytes, peeling of graphite layers, and low actual capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0070] (1) Dissolve the zinc salt and iron salt in deionized water until they are completely dissolved, then add the organic complexing agent into the iron-zinc mixed solution for constant temperature stirring to obtain a uniform slurry.

[0071] (2) Move the homogeneous slurry into the drying equipment, maintain a constant temperature in the range of 40~200°C to solidify, so that the slurry becomes a dry gel, and then cool naturally to room temperature.

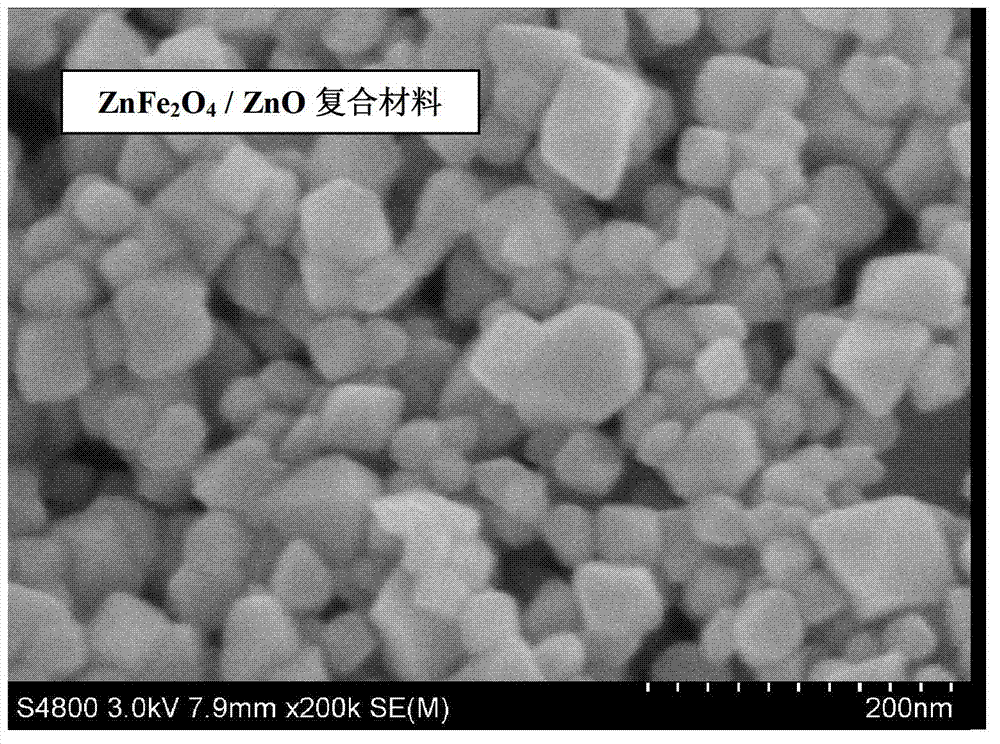

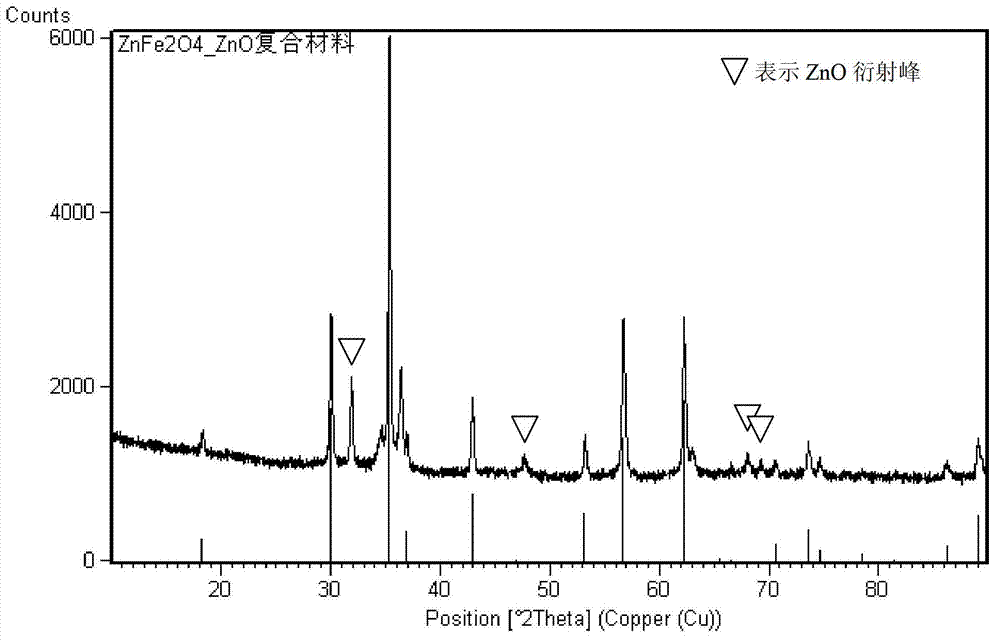

[0072] (3) Move the cooled xerogel into a calcination furnace, perform constant temperature calcination in an oxidizing atmosphere at 350-850°C, and then cool naturally to room temperature to obtain ZnFe 2 o 4 / MO (MO is ZnO or Fe 2 o 3 ) nanocomposite coarse material.

[0073] (4) Move the cooled coarse material into a ball mill or pulverizer to disperse the particles, crush them, and finally sieve the powder to obtain the negative electrode material of the lithium ion battery. The negative electrode material of the lith...

Embodiment 5~13

[0082] (1) Add the complexing agent to tap water to make an organic solution, and then add the pure phase ZnFe 2 o 4 Nano-powder and MO nano-powder are added to the solution in different proportions, and dried until the water evaporates completely to obtain a dry powder.

[0083] (2) Move the dry powder into a calcination furnace, perform constant temperature calcination in an oxidizing atmosphere at 250-850°C, and then cool naturally to room temperature to obtain a ZnFe 2 o 4 Nanoparticles with MO (MO as Fe 2 o 3 , ZnO, CoO, NiO, CuO, MnO, TiO 2 , CrO 3 、VO 2 One or a combination of at least two) nanoparticles are evenly agglomerated to form a nanocomposite material.

[0084] The specific process conditions are shown in Table 2 and Table 3.

[0085] Table 2

[0086]

[0087]

[0088] table 3

[0089]

[0090]

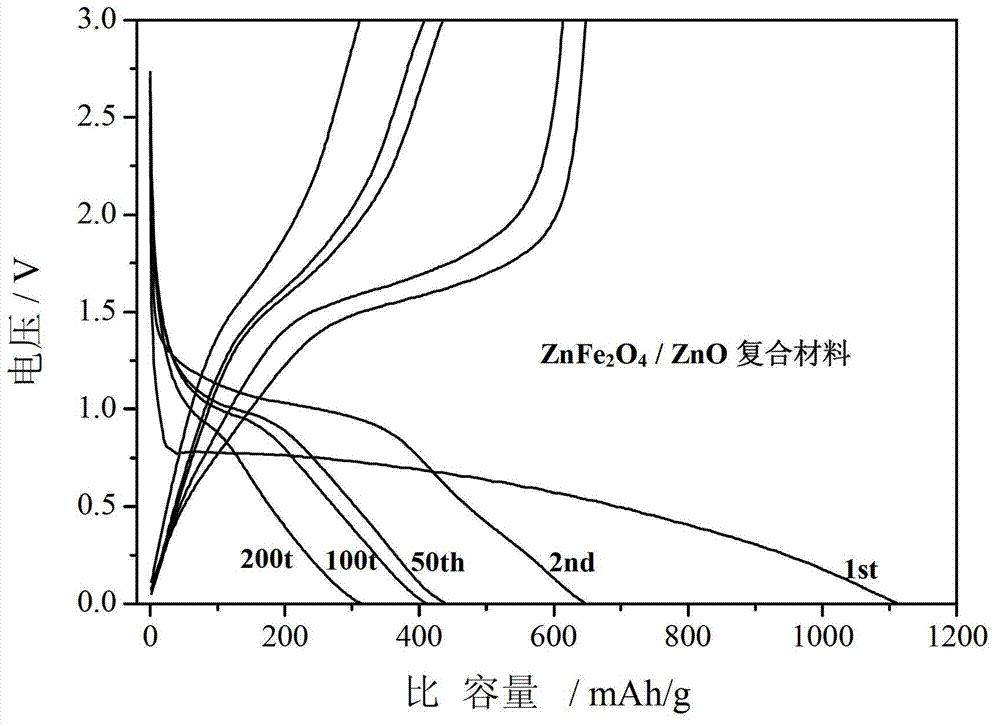

[0091] The nanocomposites prepared in Examples 1 to 13 and Comparative Examples 1 to 4 were subjected to the following performance measurements...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com