Continuous casting method of liquid-phase composite slab

A composite slab and continuous casting technology, which is applied in the field of layered metal composite material preparation, can solve the problems of product size, composite layer thickness limitation, low bonding strength of composite interface, large surface deformation of composite sheet, etc., achieving remarkable social benefits, Short production process and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

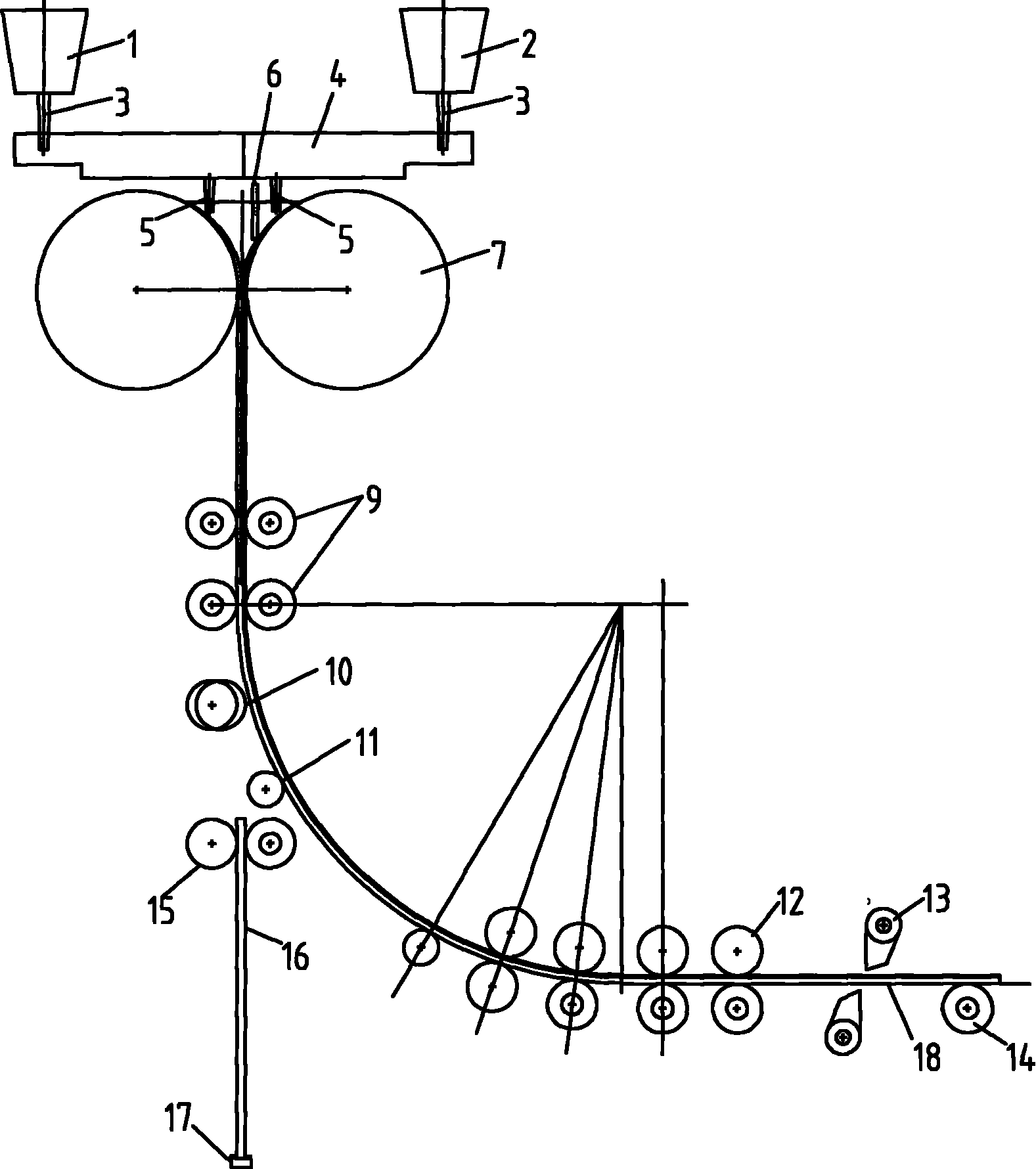

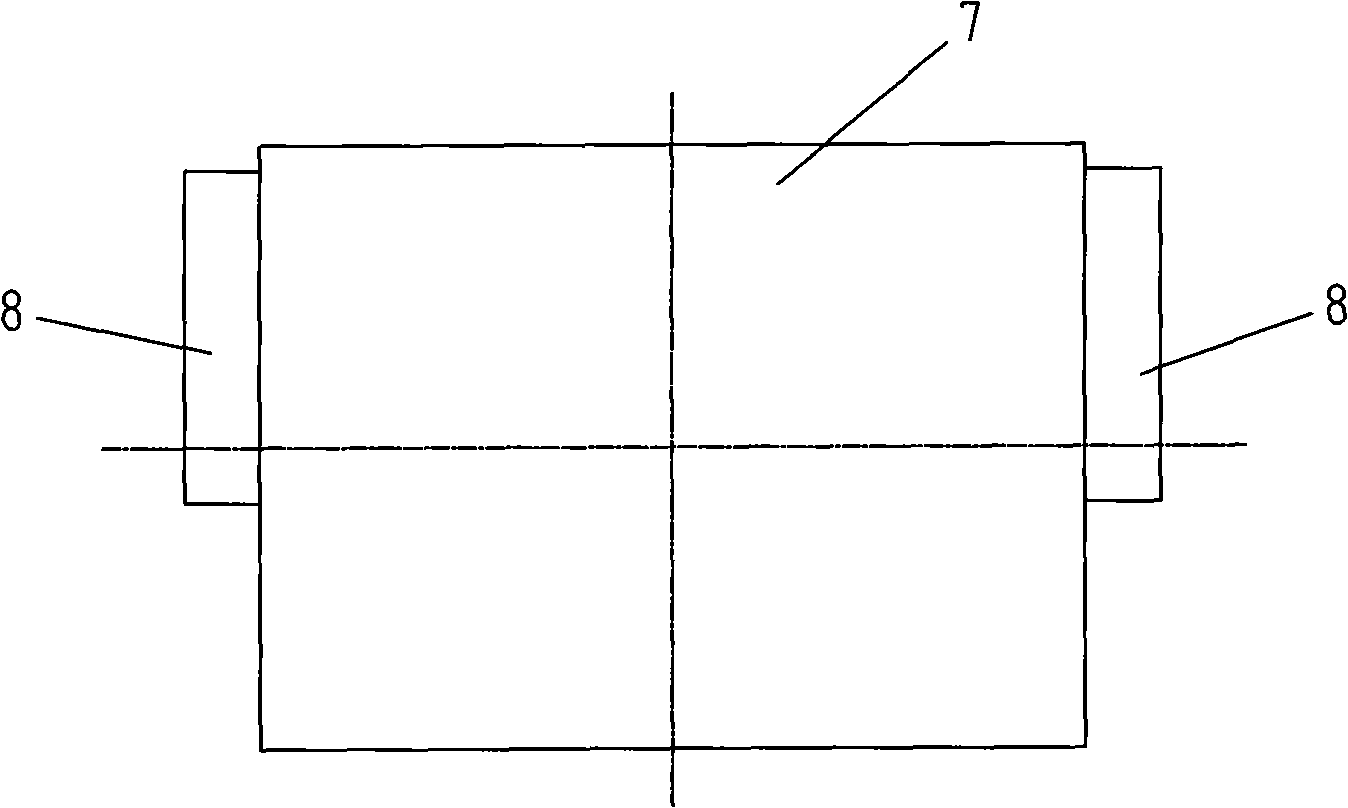

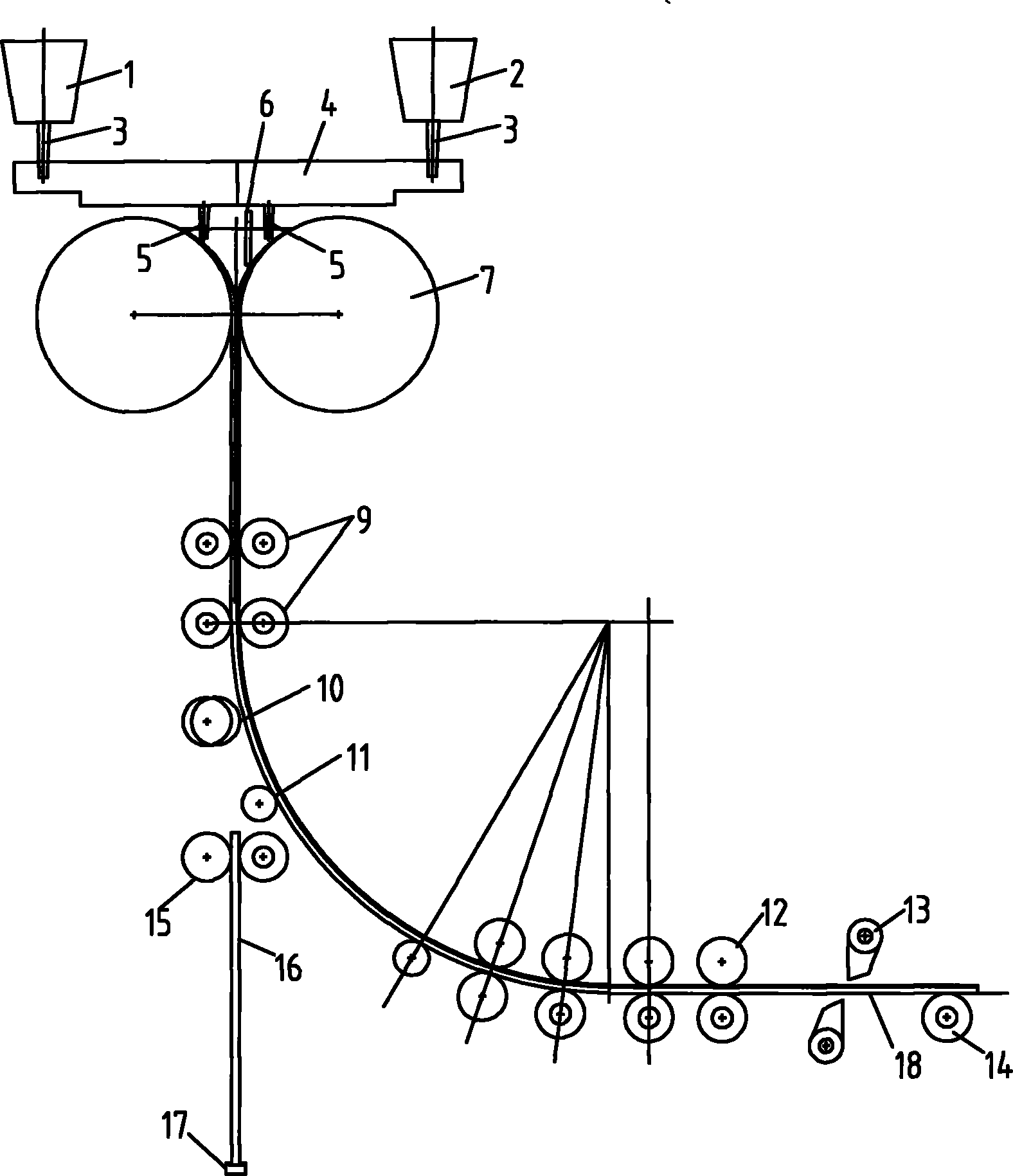

[0018] Specific examples of the present invention are attached figure 1 As shown, the liquid-phase composite slab continuous casting method is composed of a composite casting system, a roller crystallizer, a pinch top bending device, a tension straightening device, a shearing device, and a dummy bar system. It is characterized in that the composite casting system is installed above the roller mold, the pinch top bending device is installed under the roller mold, the dummy bar system is installed under the pinch and top bend device, the tension leveling device , The shearing device is installed at the rear. The composite casting system is composed of base metal casting ladle 1 , composite metal casting ladle 2 , pouring nozzle 3 , composite casting tundish 4 , and submerged nozzle 5 . The base metal casting ladle 1 and the composite metal casting ladle 2 are arranged on both sides, and a pouring nozzle 3 is installed below it. The two metal liquids are poured into the composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com