Process for producing alcohol and selectively co-producing 2-butanol by utilizing acetate and matching process system thereof

An acetate, selective technology, applied in the preparation of organic compounds, separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the fluctuation of the price of ethanol or 2-butanol products, the whole process report of the hydrogenation process, Problems such as low conversion rate and selectivity, to achieve the effect of effective utilization of reaction heat, strong market adaptability, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1 produces ethanol and co-produces the process of 2-butanol

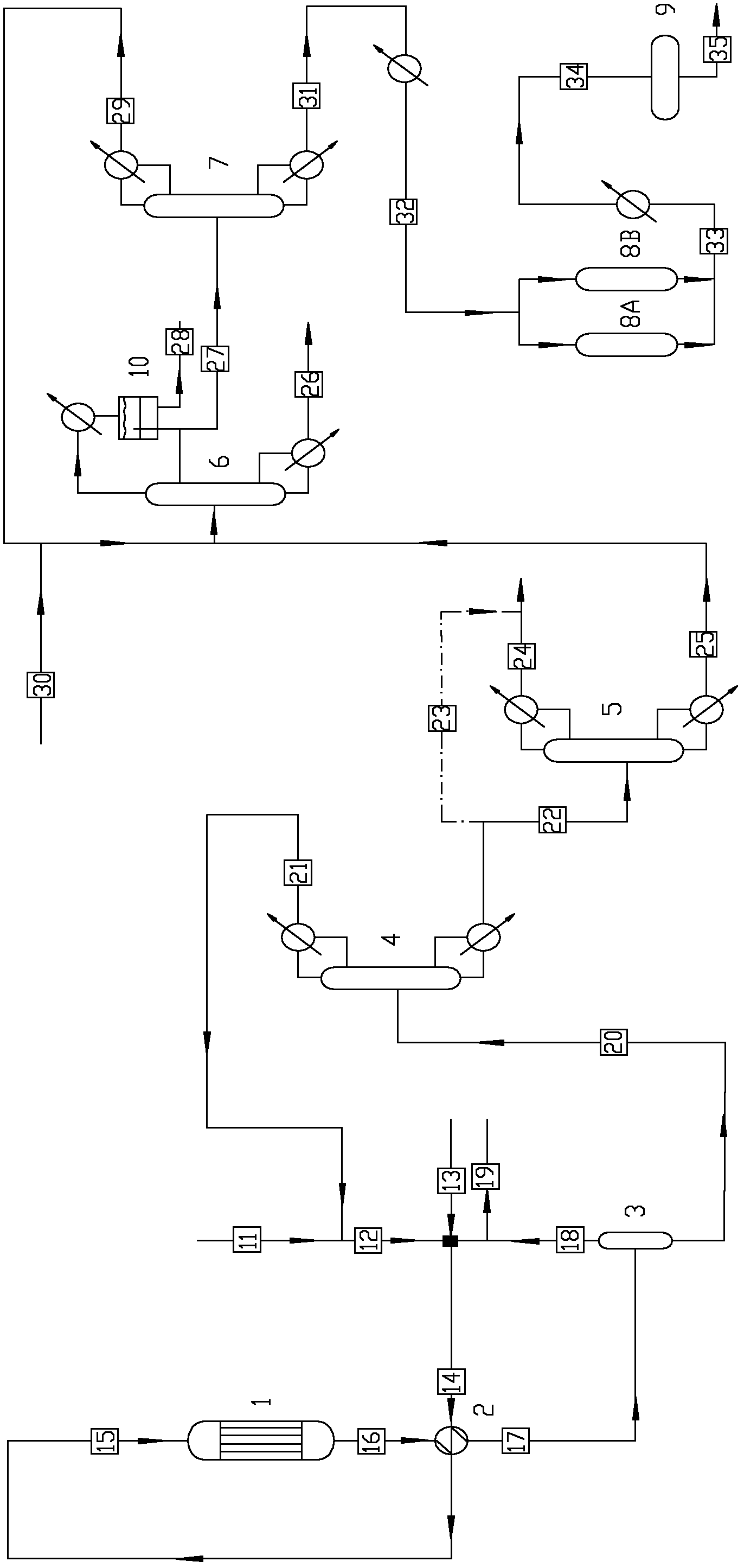

[0074] In this embodiment, various reaction components are set up with reference to the devices and processes shown in the accompanying drawings.

[0075] Industrial-grade reaction ethyl acetate raw material, after being pressurized to 2MPa, after mixing with the ethyl acetate coming out of the top of the acetate recovery tower 4, mixed with hydrogen (99.2%vol hydrogen, 0.1%volN 2 , 0.7% vol ethane) mixed, gasified and preheated to 280 ° C, added to the hydrogenation reactor 1 (inner diameter 40 mm, height 1800 mm), cooled to 50 ° C after the reaction into the gas-liquid separator 3, the gas-liquid Condensate (weight composition: 93.26% ethanol, 3.59% ethyl acetate, 0.98% water, 3.10% 2-butanol) comes out from the bottom of the separator 3, on the other hand, non-condensable gas (98.2%vol Hydrogen, 0.1%volN 2 , 1.7% vol ethane) is recycled as hydrogen raw material, and 1% of non-condensable gas i...

Embodiment 2

[0077] The process of embodiment 2 unit production ethanol products

[0078] In this embodiment, various reaction components are set up with reference to the devices and processes shown in the accompanying drawings.

[0079] Industrial-grade reaction ethyl acetate raw material, after being pressurized to 2MPa, mixed with the acetate from the top of the acetate recovery tower 4, mixed with hydrogen (99.6% vol hydrogen, 0.1% volN2, 0.3% vol ethane) After mixing, the gasification is preheated to 160°C, and it is added to the hydrogenation reactor 1 (inner diameter 40mm, height 1800mm). After the reaction, it is cooled to 50°C and enters the gas-liquid separator 3, and the condensate comes out from the bottom of the gas-liquid separator 3 (weight composition is 99.7% ethanol, 0.3% water), on the other hand, the non-condensable gas (99.3%vol hydrogen, 0.1%volN 2 , 0.6% vol ethane) is recycled as hydrogen raw material, and 1% of non-condensable gas is discharged from the system.

...

Embodiment 3-6

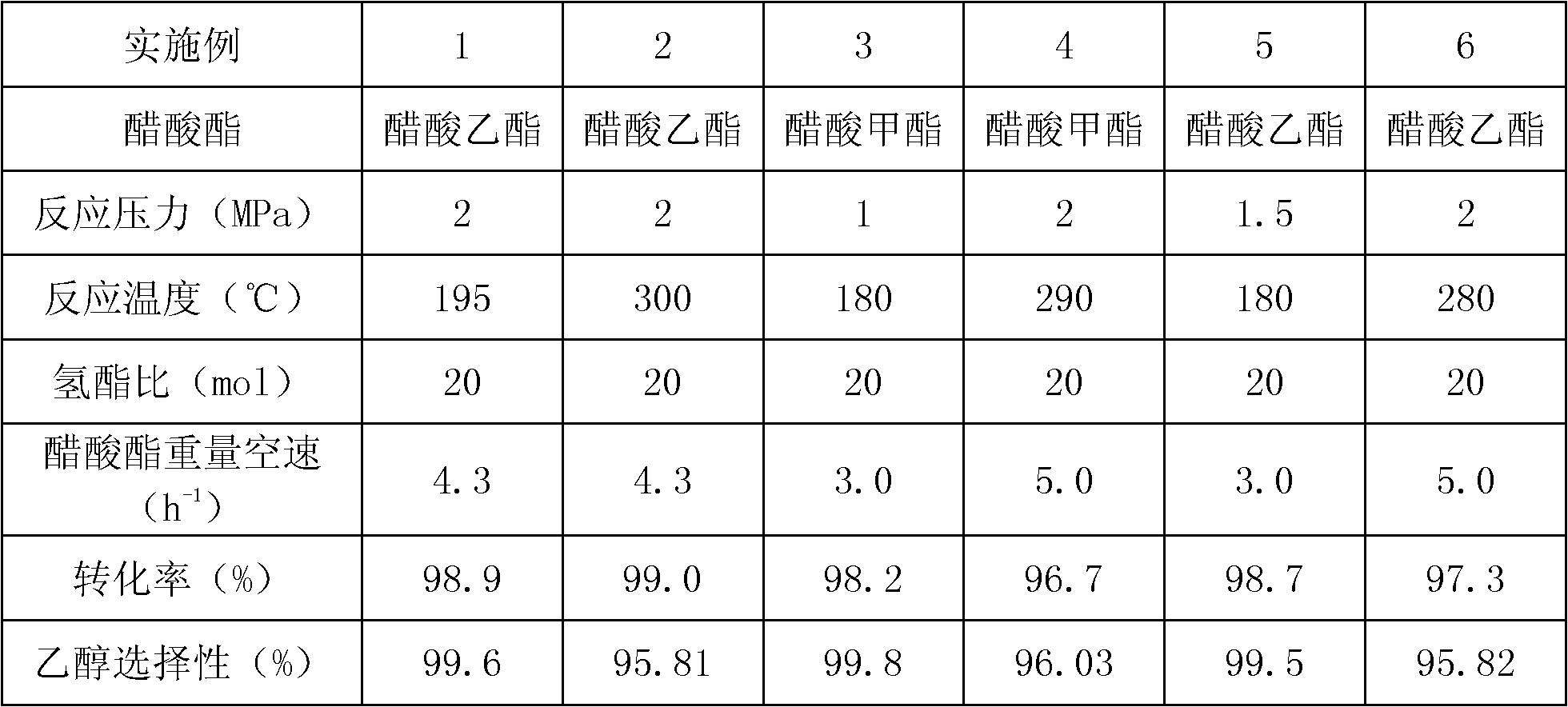

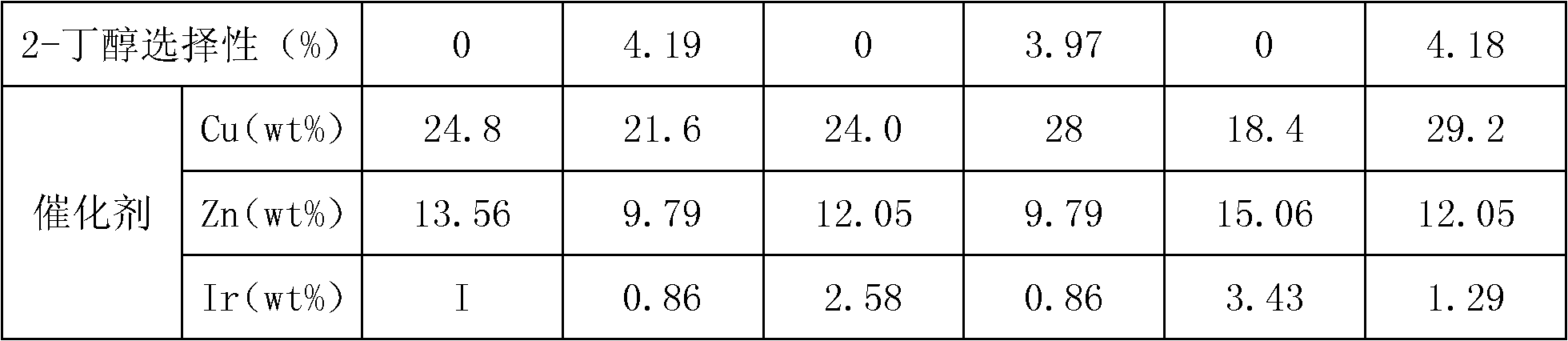

[0082] Embodiment 3-6 is the same as above-mentioned embodiment process, just wherein specific technological condition changes to some extent, see Table 1 for details (the carrier of catalyst in each embodiment is silicon dioxide).

[0083] Table 1

[0084]

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com