Robot operated on surface of oil storage tank

A technology for working robots and oil storage tanks, which is used in motor vehicles, crawler vehicles, transportation and packaging, etc., can solve the problems of large adsorption force limitation, easy disconnection of crawlers, and large application limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

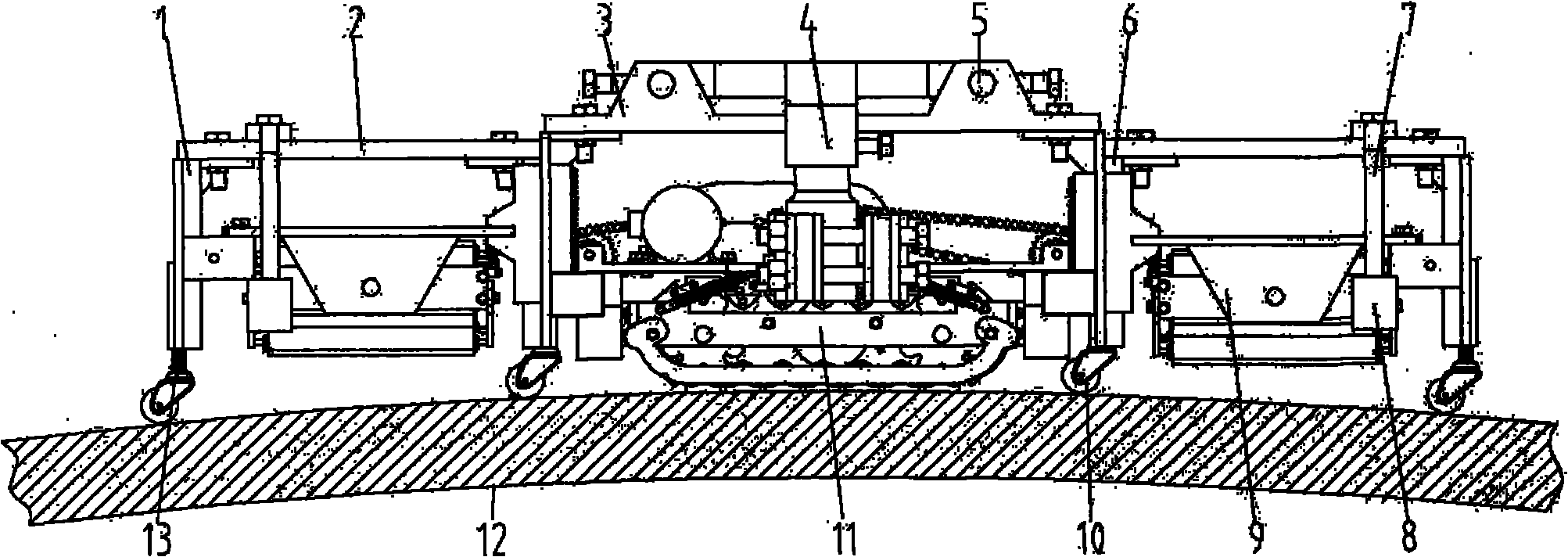

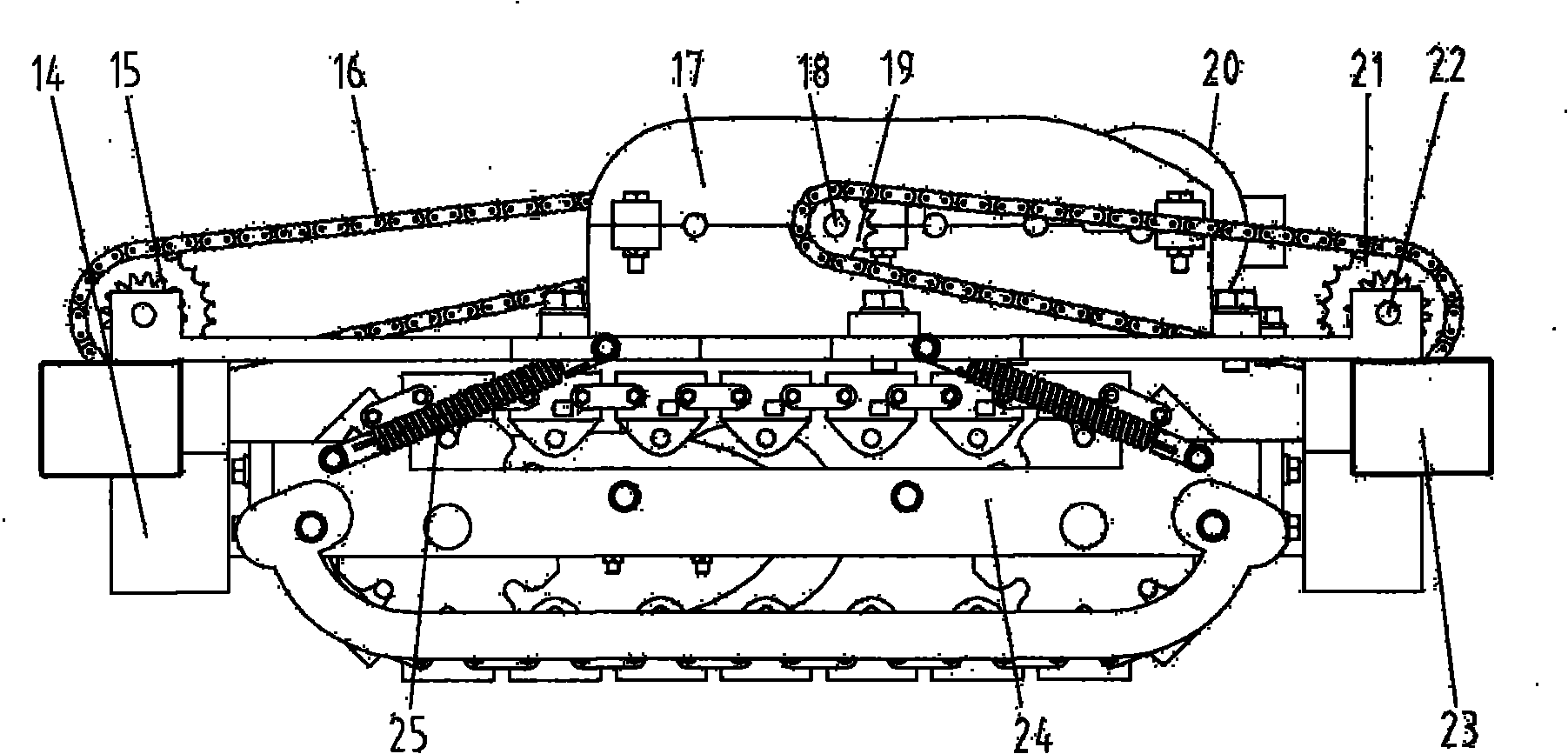

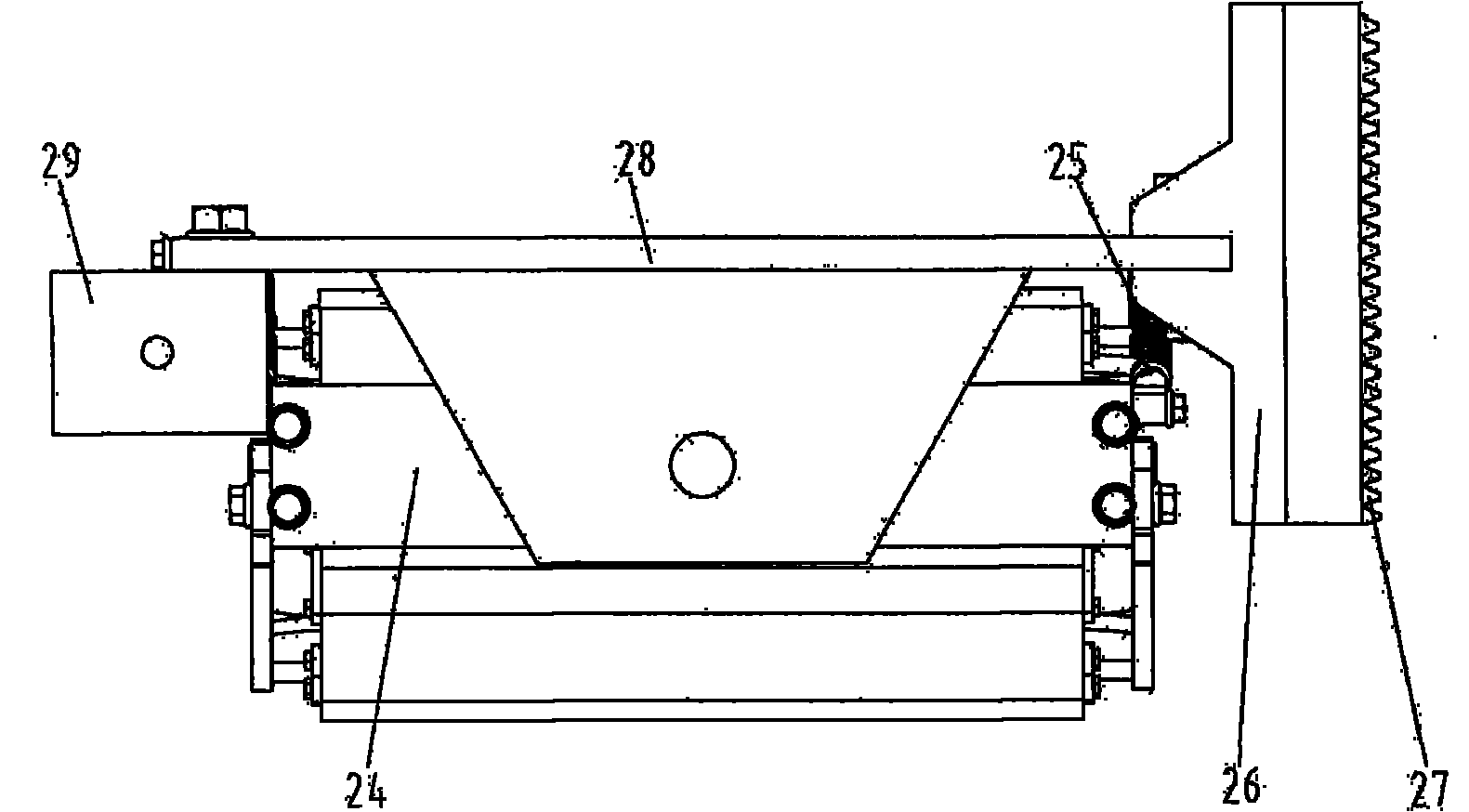

[0023] Attached below Figure 1-7 This embodiment will be described in detail.

[0024] Such as figure 1 , Figure 4 , Image 6 As shown, the utility model oil storage tank surface operation robot has a symmetrical structure, mainly composed of a pair of main sliding guide rails 6, a pair of auxiliary sliding guide rails 1, public installation platforms 2, 3, X walking unit 11, and two Y walking units. Unit 9 is composed of eight universal wheels 10.

[0025] The public installation platform is composed of a main installation platform 3 and two auxiliary installation platforms 2, and each platform is respectively connected with the corresponding main sliding guide rail 6 and the auxiliary sliding guide rail 1 by screws; two slide bars 5 are installed on the main installation platform 3, The public installation sliding block 4 is slidably connected with the slide bar 5, and the sliding adjustment screw 44 adjusts the sliding position of the public installation sliding block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com