Automatic spraying robot outside of tube

An automatic spraying and robot technology, applied in the direction of coating, manipulator, spraying device, etc., to achieve the effect of easy guarantee of operation quality, convenient and simple operation, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

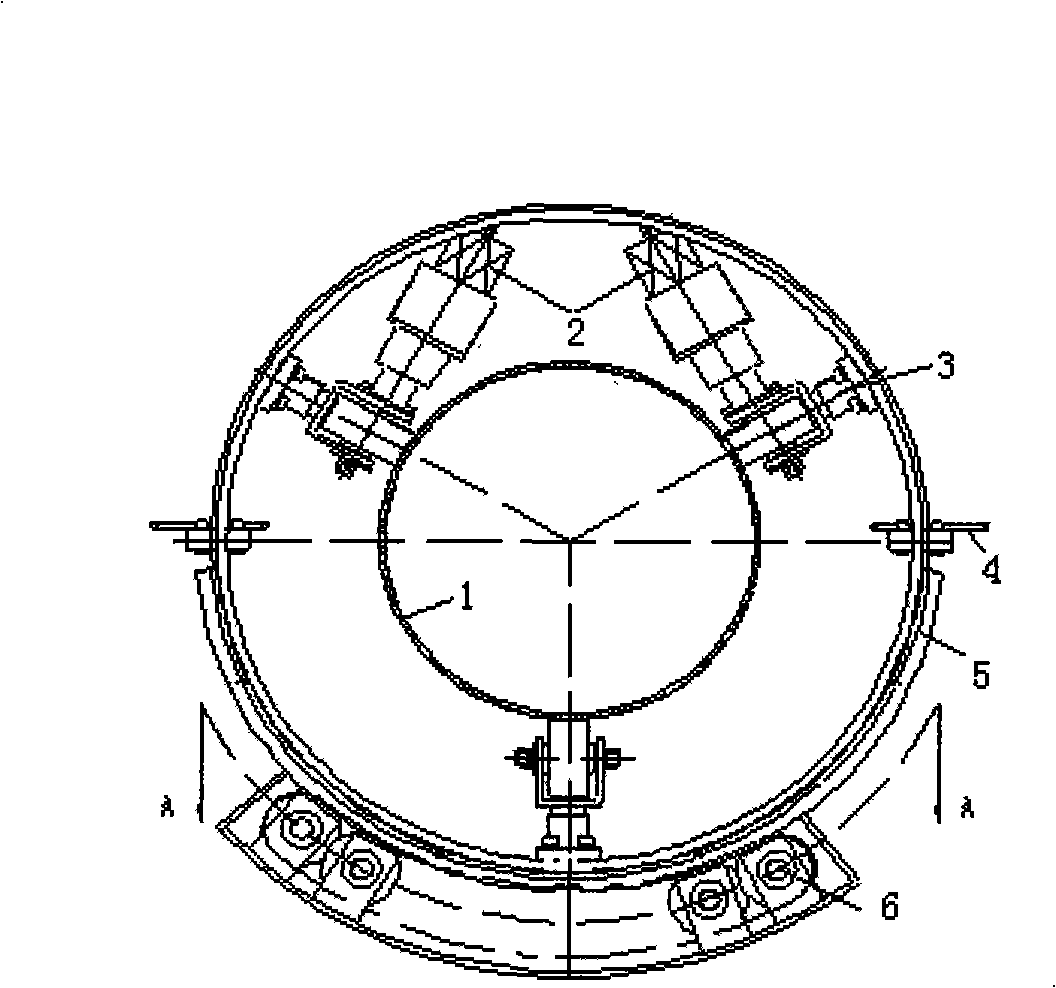

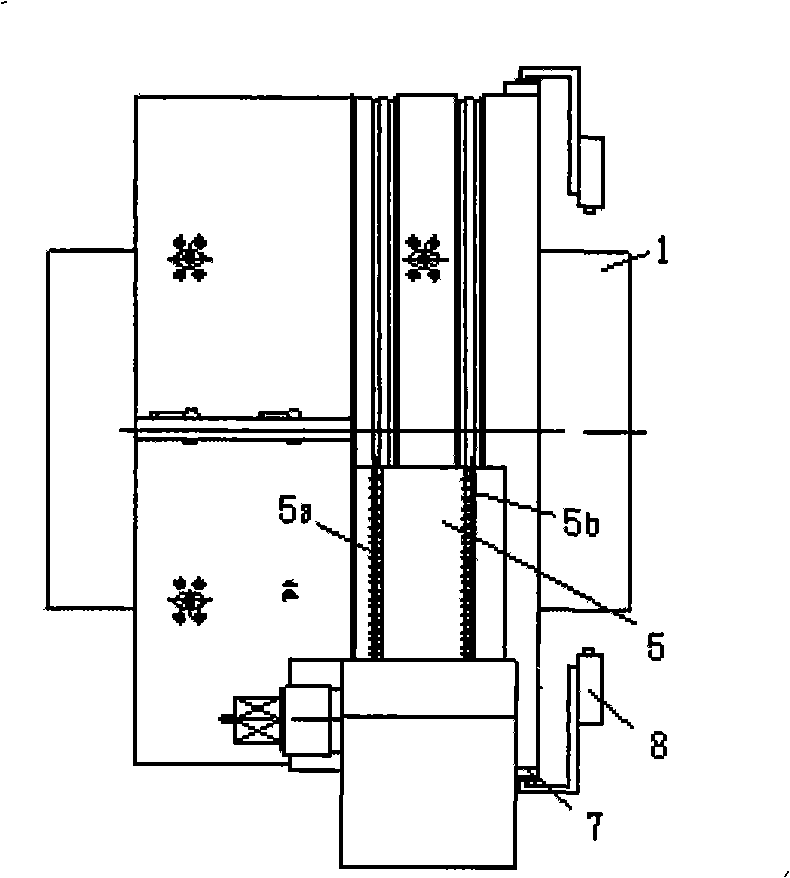

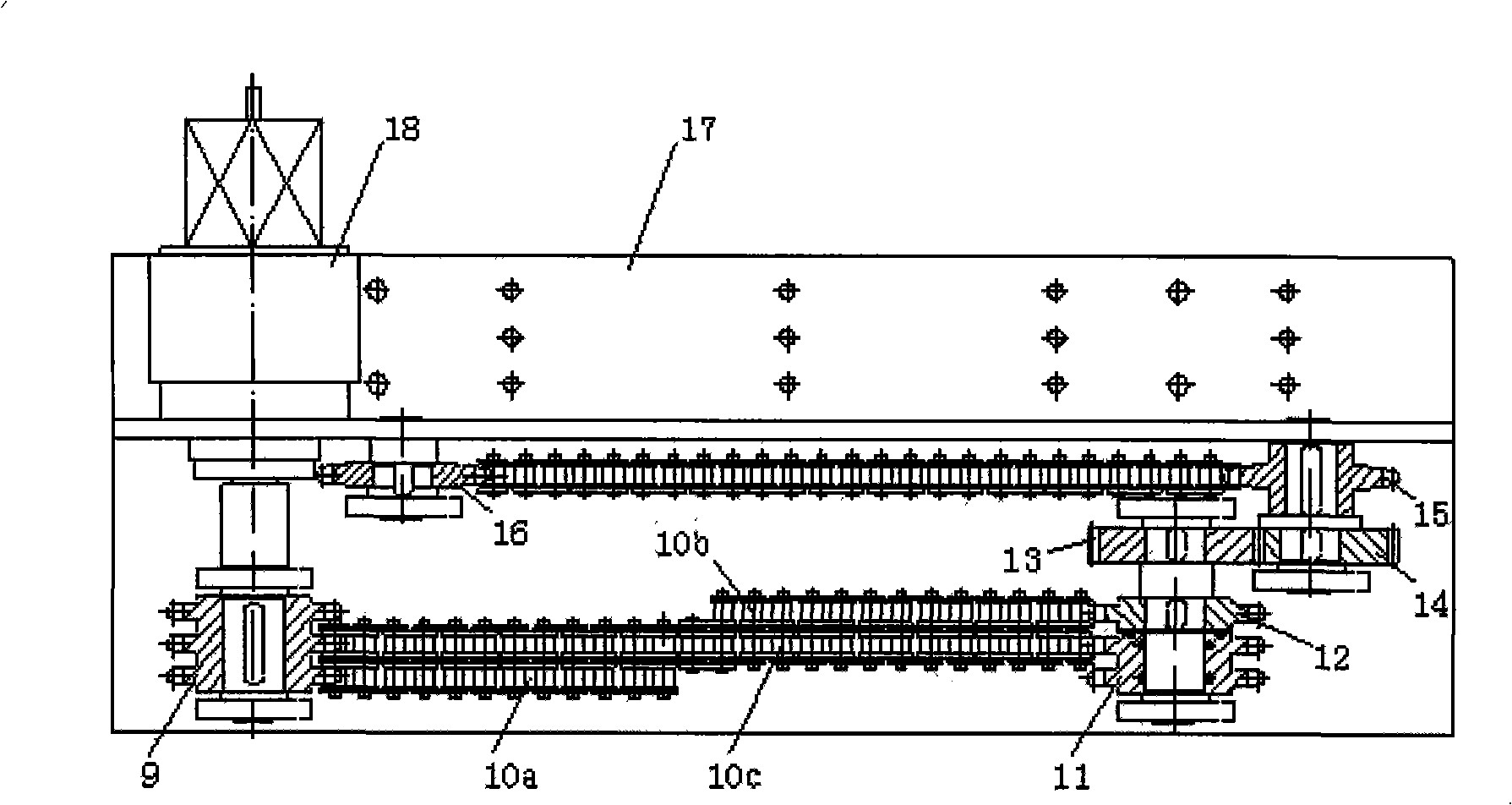

[0019] Such as figure 1 and figure 2 It is a structural principle diagram of a free-spraying robot outside the pipe adopted in the present invention. The walking part of the robot shown in the figure adopts a wheel structure and double motor drive; the circumferential motion system 6 in the figure is a reciprocating swing mechanism composed of an incomplete chain transmission system; four spray guns 8 are evenly arranged and fixed along the circumference On No. 3 sprocket 5; the robot body adopts a split structure, and the upper and lower parts (respectively called the upper body and the lower body of the pipeline robot) realize the rapid installation and disassembly of the robot through the quick operation handle 4. The quick operation handle adopts Eccentric clamping mechanism for fast clamping. Four spray guns are respectively fixed on the spray gun fixing frames of two semicircular rings, and two spray guns are installed on each semicircular fixing frame. One of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com