Comprehensive experiment table for performance parameters of harmonic reducer of robot

A technology of harmonic reducer and robot, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problem that the data is not accurate enough, cannot truly reflect the performance parameters of the harmonic reducer, etc., and achieve the effect of accurate performance parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

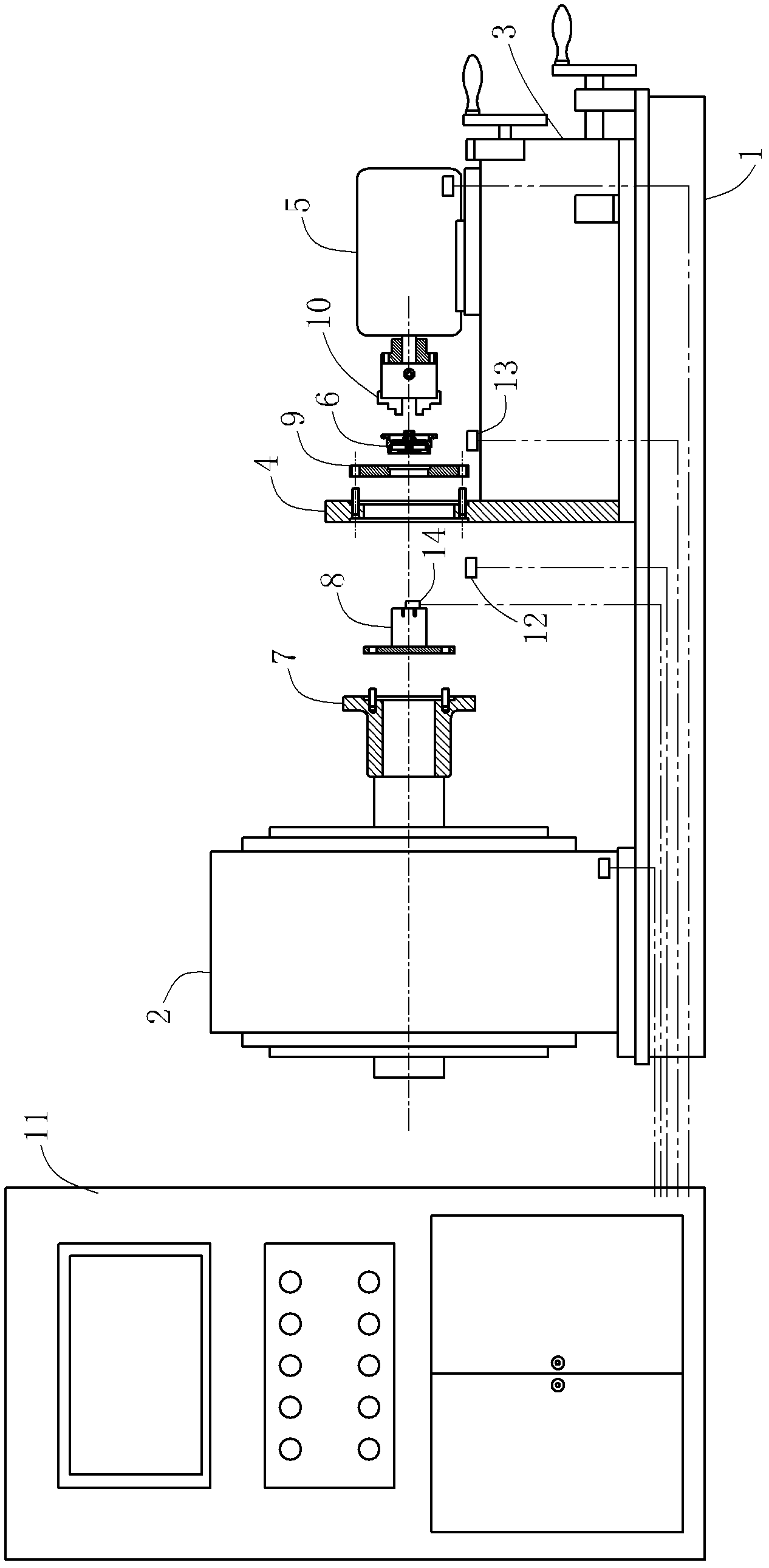

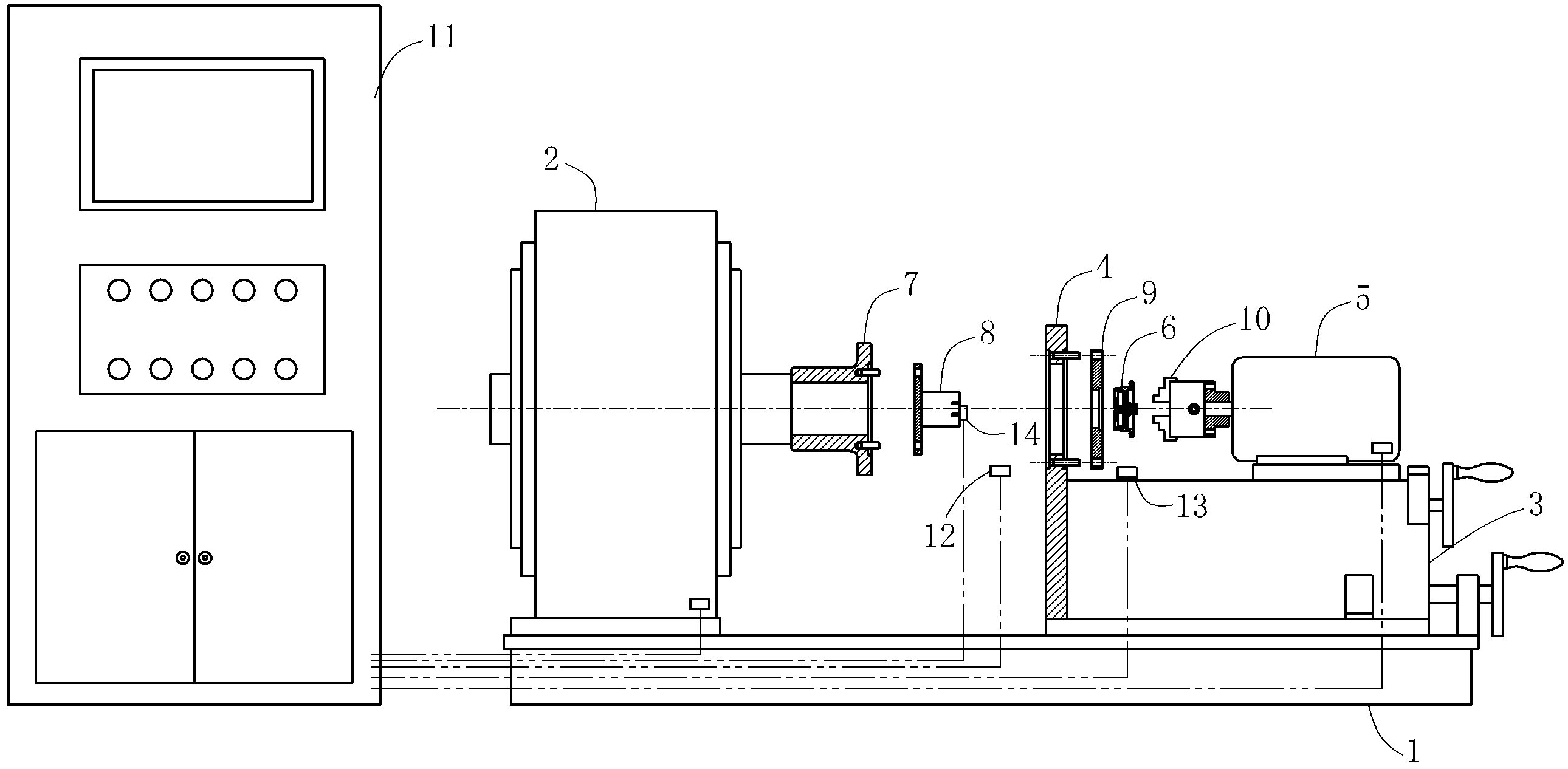

[0020] As shown in the figure, a comprehensive test bench for the performance parameters of a robot harmonic reducer mainly includes a base 1, a load loading device, a sliding seat 3, a servo motor 5 and a control unit 11. Wherein, the load loading device is installed on the base 1, the input end of the load loading device is connected to the flexspline of the harmonic reducer 6; the sliding seat 3 is slidably installed on the base 1 and sliding For the load loading device, usually the sliding seat 3 is slidably mounted on the base 1 through a sliding rail. The sliding seat 3 is provided with a fixing bracket 4 for fixing the rigid wheel of the harmonic reducer 6; the servo motor 5 Slidingly mounted on the sliding seat 3, the servo motor 5 slides to the fixed bracket 4, usually the servo motor 5 is slidingly mounted on the sliding seat 3 through a sliding rail, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com