Large-size true triaxial hydraulic fracturing simulation test device and test method

A hydraulic fracturing and simulation test technology, which is applied to measuring devices, using stable tension/pressure testing materials, instruments, etc. Problems such as poor size applicability to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

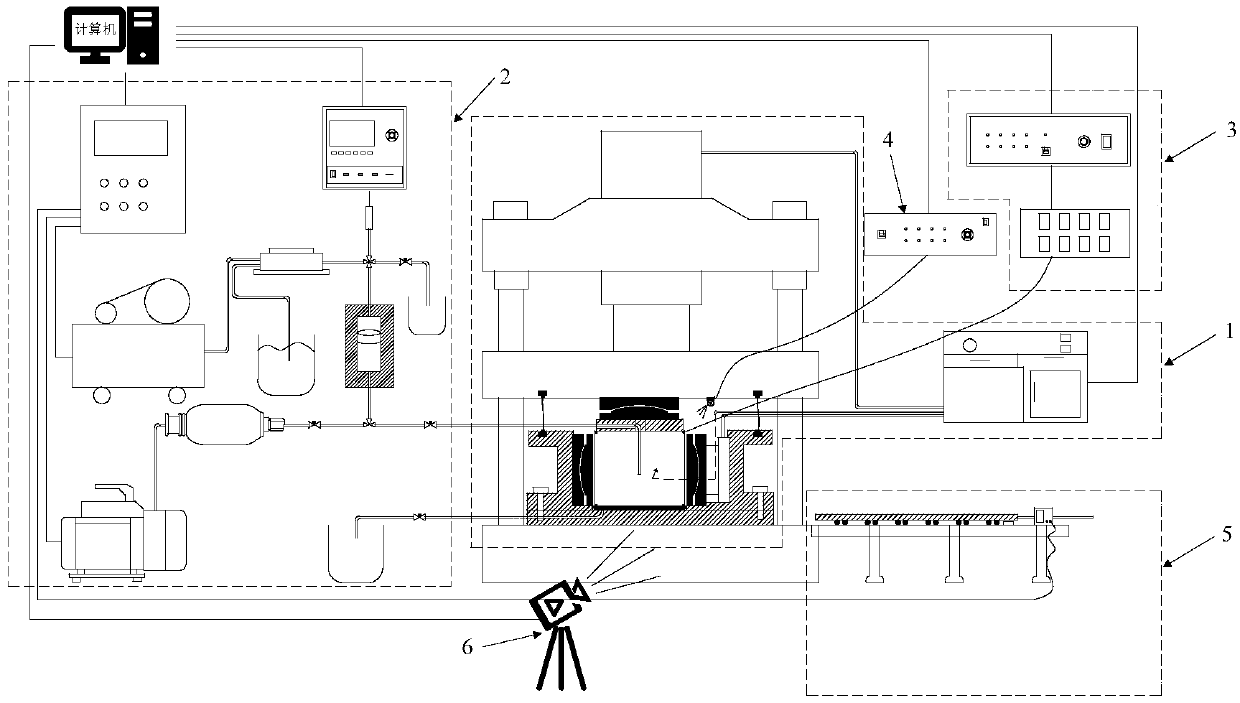

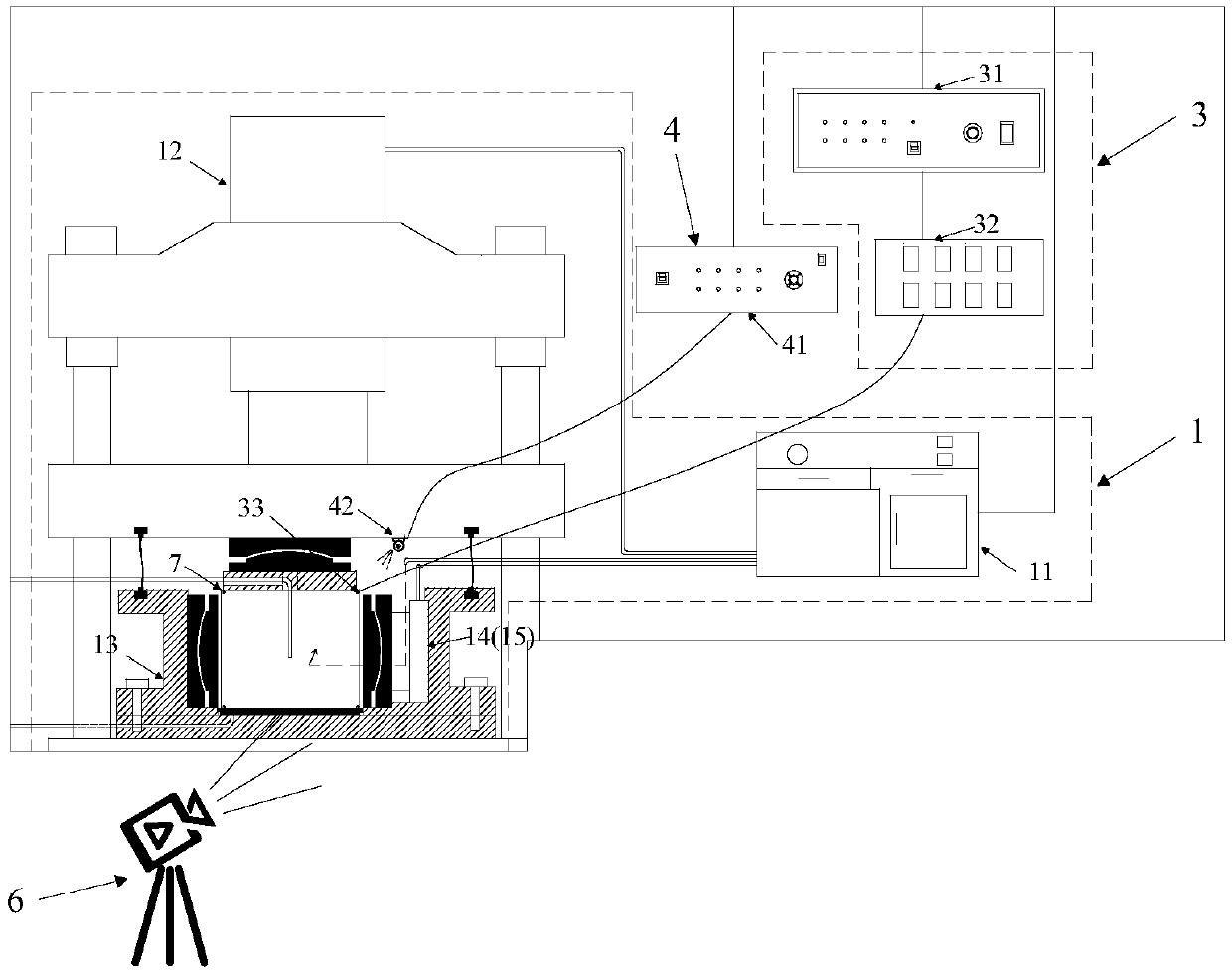

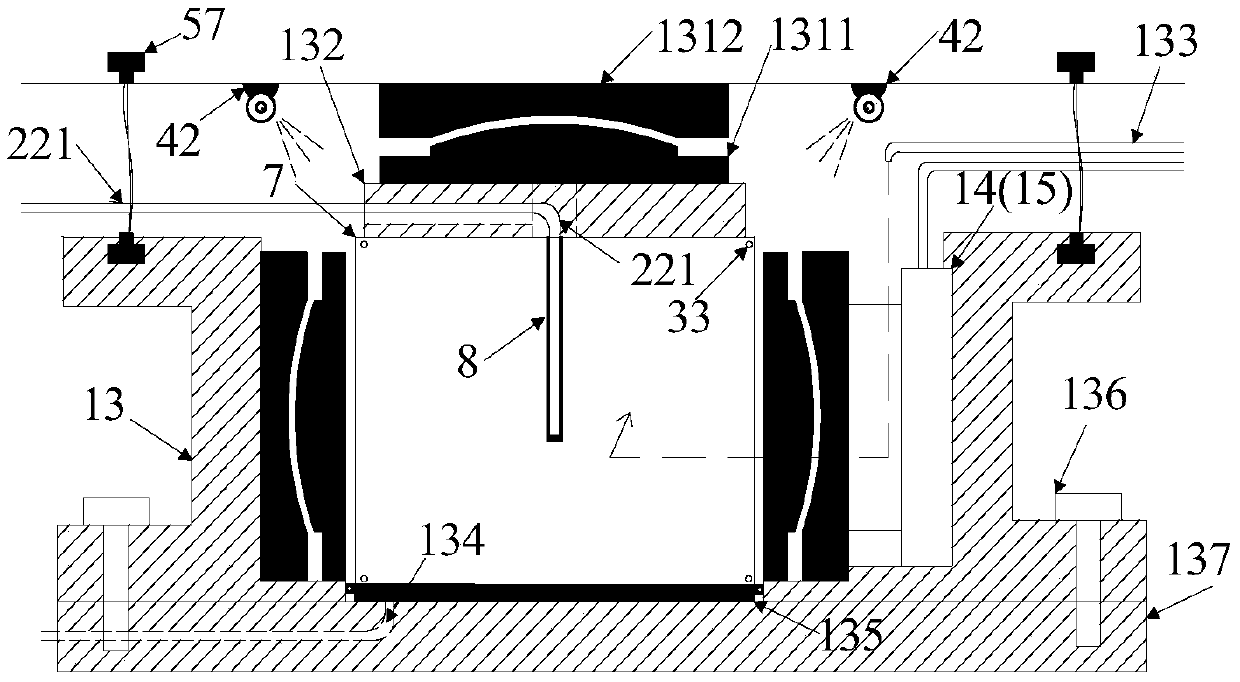

[0050] like figure 1 and figure 2 As shown, the large-scale true triaxial hydraulic fracturing simulation test device of this embodiment includes a large-scale true triaxial loading module 1 for applying triaxial loads to the large-scale cube sample 7 to simulate in-situ stress, and is used to apply a triaxial load to the sample. The hydraulic servo pumping module for internal delivery of high-pressure fracturing fluid 2, the acoustic emission positioning module for real-time monitoring of the hydraulic fracture expansion law in the hydraulic fracturing process 3, the sample loading and unloading module for sample loading and unloading 5, for In the test process, the infrared monitoring module 4 for real-time monitoring of the internal conditions of the triaxial loading chamber 13, the high-speed camera 6 and the computer for the uniaxial hydraulic fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com