Method and system for simulating multisystem synchronous numerical-control processing

A simulation method and technology of a simulation device, which are applied in educational appliances, instruments, teaching models, etc., can solve the problems of single training function, waste of training resources, and lack of realism, and achieve flexible and changeable training forms, improve utilization, and achieve The effect of optimizing the configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

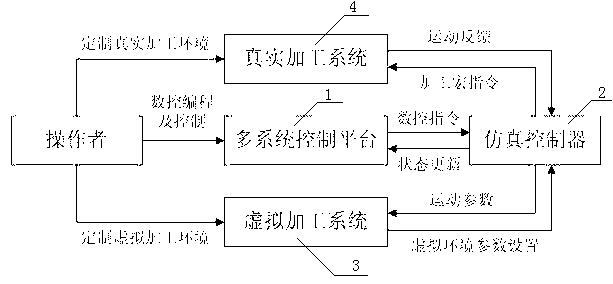

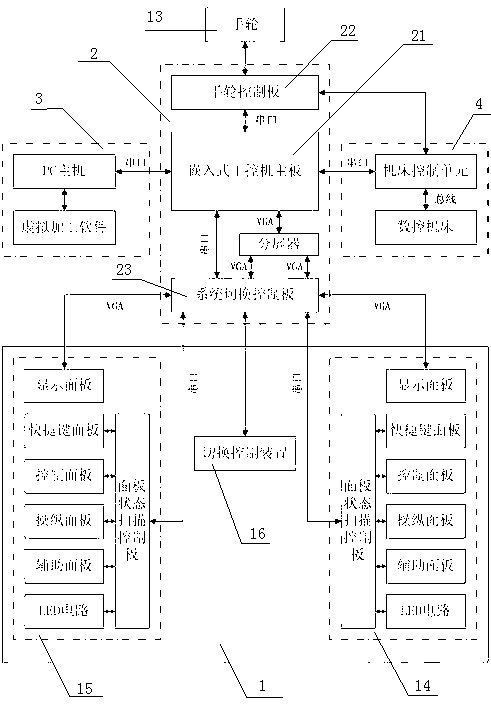

[0042] see figure 1 , the multi-system synchronous numerical control machining simulation method of the present invention, firstly, the operator uses the virtual machining system to order the virtual machining environment, customizes the real machining environment in the real machining system, and then uses the multi-system control platform to select a numerical control system panel, and proceeds NC programming and control, use the communication interface to send NC commands to the simulation controller, and the simulation controller performs simulation calculations. On the one hand, the tool motion parameters are sent to the virtual processing system, and the virtual processing system uses virtual cutting processing simulation algorithms to perform graphic simulation calculations. , to complete the virtual proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com