Efficient multipurpose metal cleaning agent

A metal cleaning agent and multi-functional technology, applied in the field of chemistry, can solve the problems of unreasonable chemical composition of metal cleaning agents and cannot meet the requirements at the same time, and achieve the effects of fast degreasing and decontamination, low production cost and small usage amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

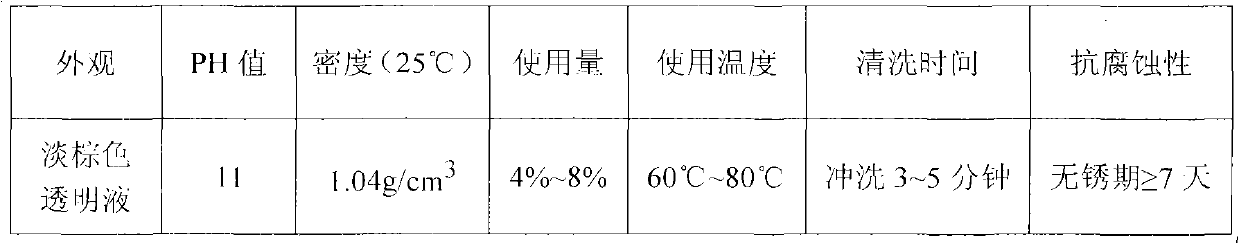

Embodiment 1

[0049] Embodiment 1: The preparation method of efficient multifunctional metal cleaning agent is as described above, and its chemical composition is as follows: OP-10 7%, AEO-9 7%, 6501 7%, C 6 h 14 o 2 7%, C 18 h 34 o 2 4%, N(CH 2 CH 2 Oh) 3 6%, Na 2 SiO 3 3%, NaBO 2 4H 2 O 1.5%, Na 2 MoO 4 2H 2 O 0.8%, H-580 0.2%, H 2 O 56.5%. Rinse the steel parts with an aqueous solution with a working temperature of 70°C and a cleaning agent dosage of 5% for 3-5 minutes, and the surface of the steel parts will be clean; the steel parts will not corrode after 24 hours at 55.6°C (100°F) and a relative humidity of 100%. Indoor hanging piece: no rust period ≥ 7 days.

Embodiment 2

[0050] Embodiment 2: The preparation method of high-efficiency multifunctional metal cleaning agent is as described above, and its chemical composition is as follows: OP-106%, AEO-96%, 65016%, C 6 h 14 o 2 7%, C 18 h 34 o 2 4%, N(CH 2 CH 2 Oh) 3 6%, Na 2 SiO 3 3%, NaBO 2 4H 2 O 1.5%, Na 2 MoO 4 2H 2 O 0.8%, H-580 0.2%, H 2 O 59.5%. Rinse the steel parts with an aqueous solution with a working temperature of 70°C and a cleaning agent dosage of 5% for 3-5 minutes, and the surface of the steel parts will be clean; the steel parts will not corrode after 24 hours at 55.6°C (100°F) and a relative humidity of 100%. Indoor hanging piece: no rust period ≥ 7 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com