Sealing system of vehicle window glass

A technology for window glass and sealing system, which is applied in the direction of engine sealing, sealing device, vehicle parts, etc. Low price, improving bond strength, and the effect of enhancing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

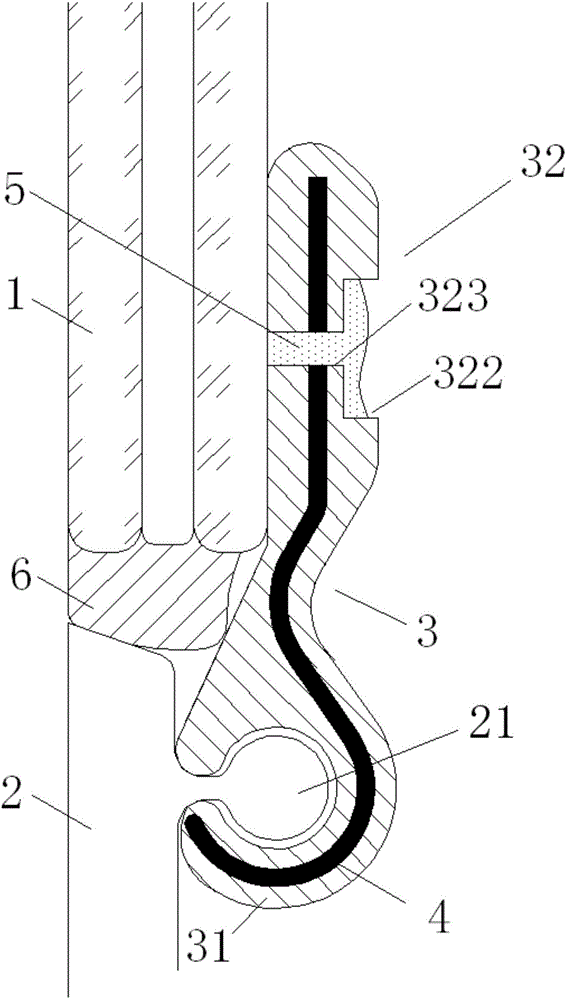

Embodiment 1

[0045] Such as figure 1 As shown, a sealing system for the window glass that is used to connect the windshield 1 and the water tank cover 2 together includes a hook-shaped seal 3 and a sealing lip 6 that are hook-shaped in cross section, and the hook-shaped seal 3 includes a holding part 32 and an elastic arm 31, the outer side of the holding part 32 is connected to the inner side of the windshield 1 in a bonding manner, and the elastic arm 31 is tightly fastened with the rib 21 of the water tank cover 2, The sealing lip 6 is tightly fitted between the lower edge of the windshield 1 and the upper edge of the water tank cover 2 and is flush with the outer surfaces of the windshield 1 and the water tank cover 2. The inside of the holding part 32 is provided with a A glue storage tank 322 for storing the adhesive 5 , at least one row of through holes 323 arranged longitudinally along the holding portion 32 is opened between the glue storage tank 322 and the windshield 1 .

[004...

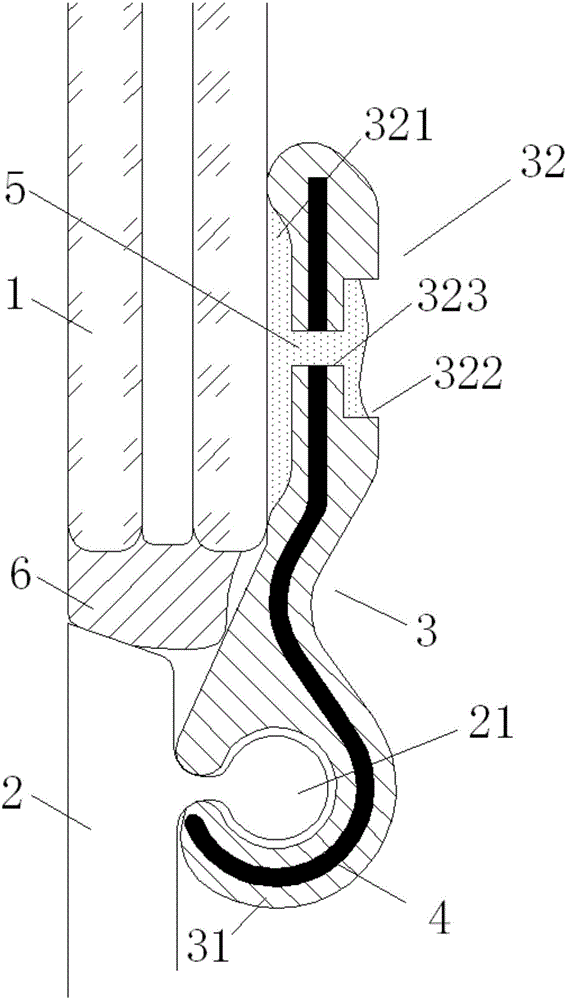

Embodiment 2

[0049] Such as figure 2 As shown, a sealing system for the window glass that is used to connect the windshield 1 and the water tank cover 2 together includes a hook-shaped seal 3 and a sealing lip 6 that are hook-shaped in cross section, and the hook-shaped seal 3 includes a holding part 32 and an elastic arm 31, the outer side of the holding part 32 is connected to the inner side of the windshield 1 in a bonding manner, and the elastic arm 31 is tightly fastened with the rib 21 of the water tank cover 2, The sealing lip 6 is tightly fitted between the lower edge of the windshield 1 and the upper edge of the water tank cover 2 and is flush with the outer surfaces of the windshield 1 and the water tank cover 2. The outer side of the holding part 32 is provided with a A glue-holding tank 321 for accommodating the adhesive 5, a glue-storing tank 322 is provided on the inside of the holding portion 32, and at least one row is provided between the glue-holding tank 321 and the glu...

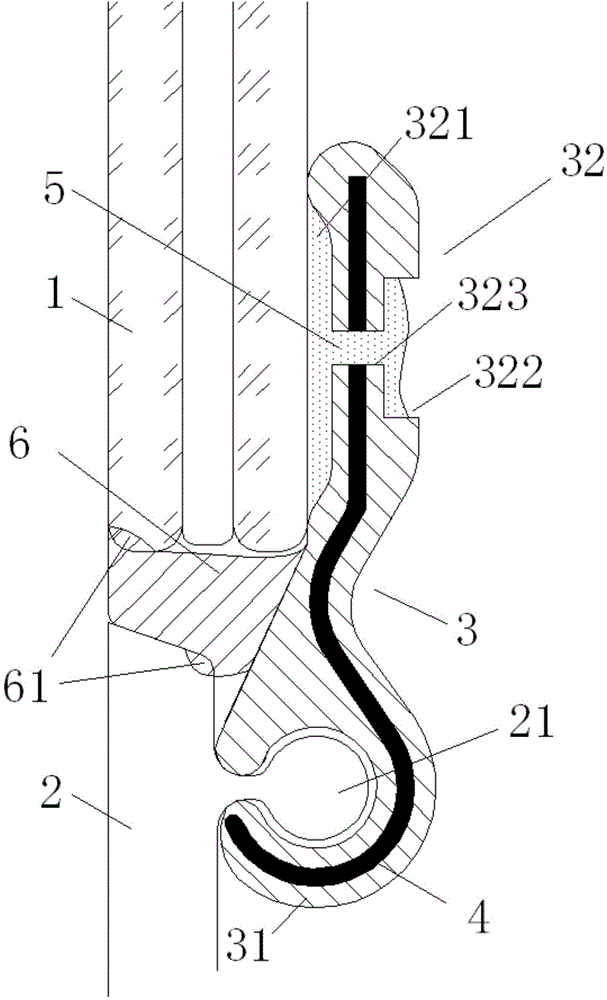

Embodiment 3

[0053] Such as image 3 As shown, a sealing system for connecting the windshield 1 and the water tank cover 2 together, the window glass includes a hook-shaped seal 3 and a sealing lip 6 with a hook-shaped cross section, and the hook-shaped seal 3 It includes a holding part 32 and an elastic arm 31, the outer side of the holding part 32 is connected to the inner side of the windshield 1 in a bonding manner, and the elastic arm 31 is sealed and fastened with the rib 21 of the water tank cover 2, so The sealing lip 6 is tightly fitted between the lower edge of the windshield 1 and the upper edge of the water tank cover 2 and is flush with the outer surfaces of the windshield 1 and the water tank cover 2. The glue holding tank 321 of the adhesive 5, the inside of the holding part 32 is provided with a glue storage tank 322, and at least one row is provided between the glue holding tank 321 and the glue storage tank 322 along the holding part. 32 longitudinally arranged through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com