Oriented rotational guide drilling tool

A rotary steerable drilling and pointing technology, which is applied in directional drilling, rotary drilling, rotary drilling rigs, etc., can solve the problems of restricting the control of the wellbore trajectory, relying on the softness of the formation, and low control accuracy, achieving simple structure, The effect of prolonging the service life and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the embodiments.

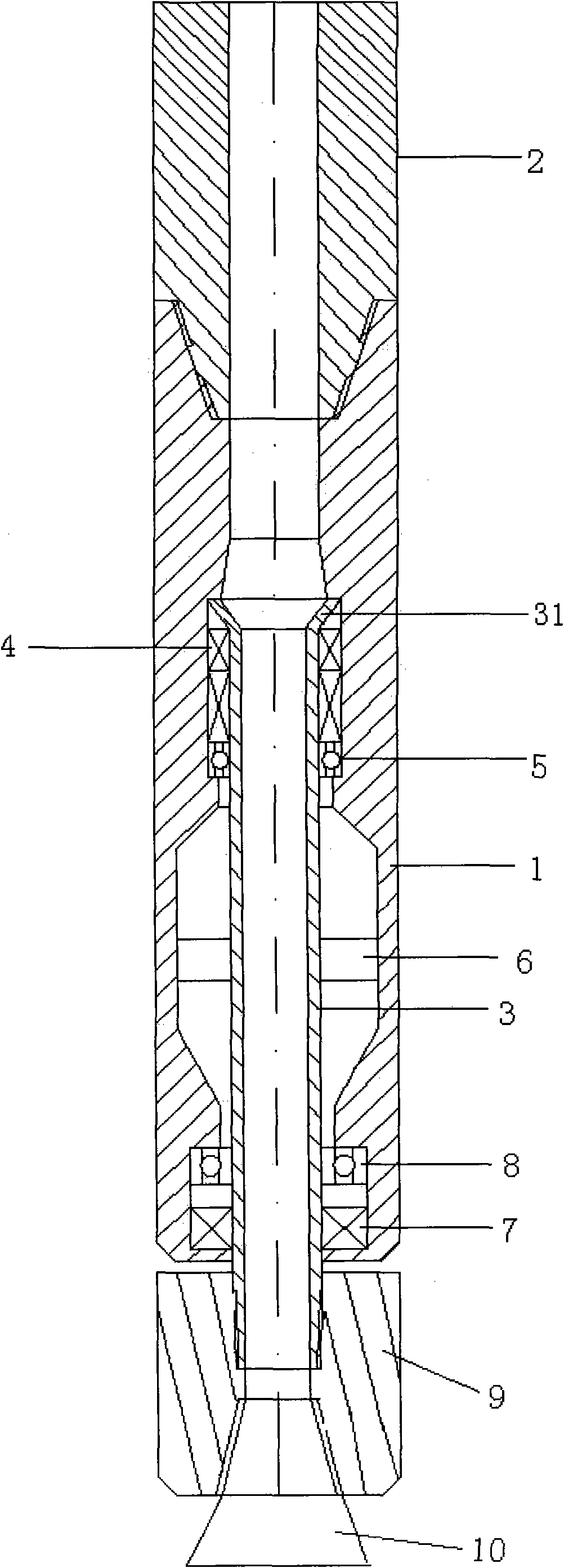

[0009] like figure 1 As shown, the present invention includes a hollow casing 1 with both ends transparent, and the casing 1 communicates with a hollow drill collar 2 through a female snap (not shown) at its upper end. A hollow mandrel 3 is inserted into the shell 1, and a cup-shaped mouth 31 is provided on the upper port of the mandrel 3, which is close to the inner wall of the shell. Close to the outer wall of the mandrel 3 of the cup-shaped mouth 31, an upper floating seal assembly 4 and an upper floating bearing 5 for supporting the mandrel 3 are fixed in turn from top to bottom, so that not only the mandrel in the drilling process can 3 does not bear the action of axial drilling pressure, but also enables the mandrel 3 to have a degree of freedom in the rotating state, and the dynamic friction force reaches the minimum during the rotating process. Because the cup-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com