Harmless waste plastic treatment equipment and method

A technology of harmless treatment and waste plastics, which is applied in the treatment of hydrocarbon oil, hydrocarbon oil treatment products, preparation of liquid hydrocarbon mixture, etc., can solve the problems of secondary pollution, insufficient cracking, high equipment cost, etc., and prolong the service life , Improve safety, and have a wide range of practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

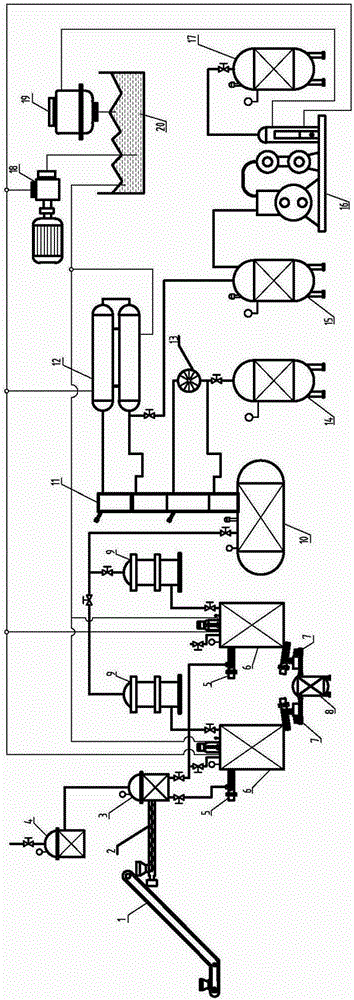

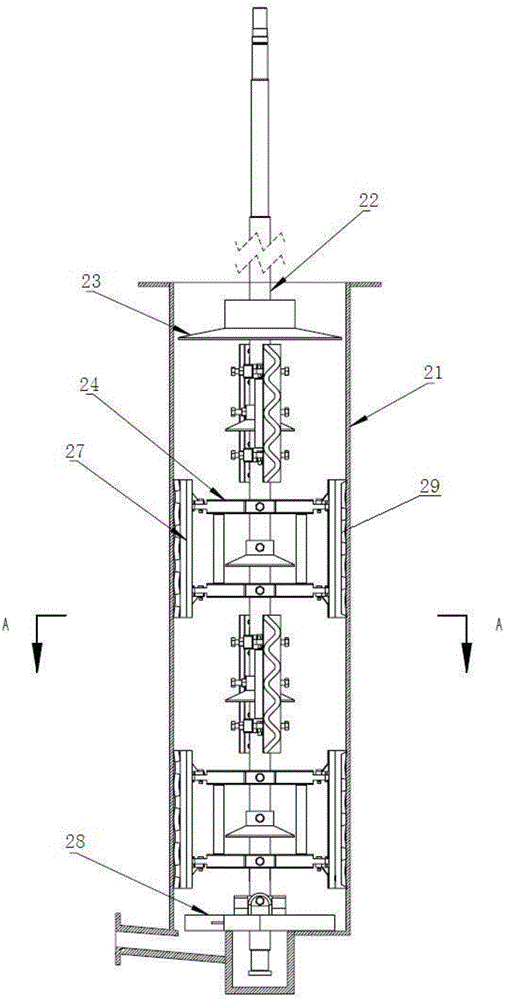

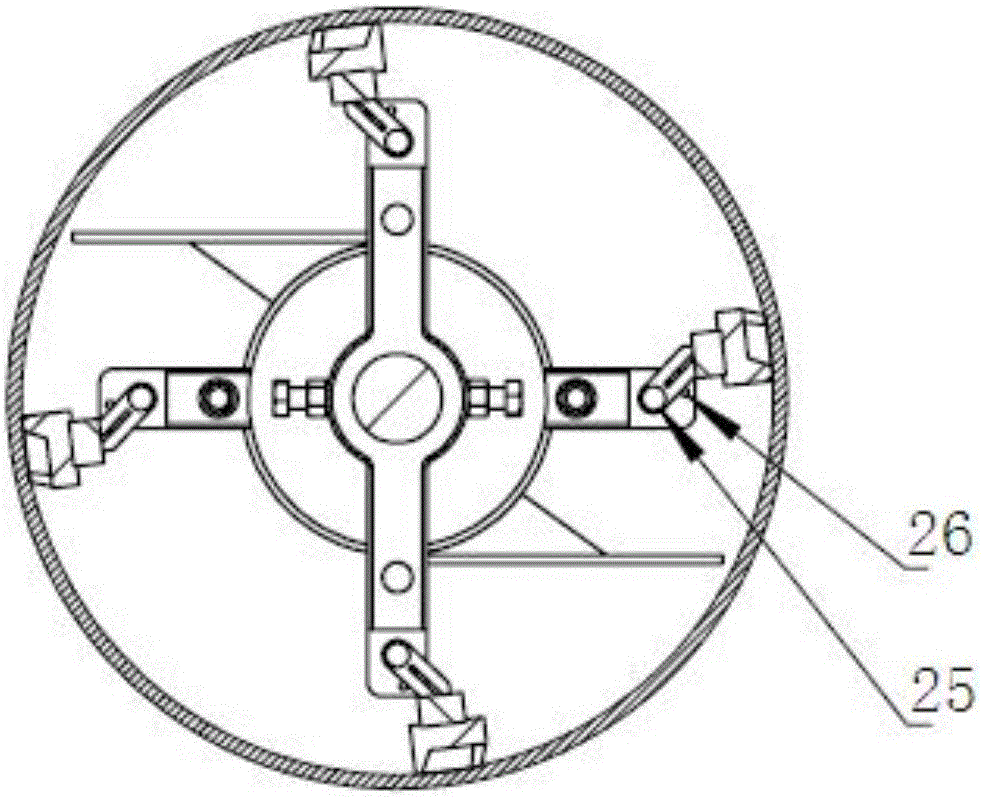

[0029] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0030] as attached figure 1 As shown, the present invention consists of belt conveyor 1, large screw feeder 2, dechlorination splitter 3, lye neutralization tank 4, small screw feeder 5, cracking kettle 6, carbon outlet system 7, carbon powder collection Tank 8, catalytic reforming tower 9, reboiler 10, fractionating tower 11, condenser 12, air cooler 13, diesel storage tank 14, gasoline storage tank 15, compressor unit 16, non-condensable gas storage tank 17, water pump 18 , a cooling tower 19 and a pool 20, each part of the whole set of equipment is placed in a frame composed of multiple steel supports, the belt conveyor is connected with the hopper of the large screw feeder, and the flange at one end of the large screw feeder is connected to the ejector Flange connection on the side of the chlorine splitter; there are two outlets at the bottom of the dechlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com